Surface Mount Technology (SMT) offers several advantages over Through-Hole Technology (THT), making it a superior choice for modern electronic manufacturing. SMT's compact design enables higher component density, miniaturization, and reduced material consumption, resulting in cost savings and space efficiency. Automation in SMT accelerates production cycles, improves product quality, and reduces labor costs. With SMT, designers have more flexibility to optimize for performance and space efficiency. As the electronics industry continues to evolve, understanding the benefits of SMT is vital for manufacturers seeking to improve production efficiency and stay competitive – and there's more to explore in the world of SMT.

Key Takeaways

- SMT components are up to 75% smaller than through-hole counterparts, enabling compact designs and higher component density on PCBs.

- Automation in SMT accelerates manufacturing cycles, improves product quality, and reduces labor costs by up to 60% compared to THT.

- SMT technology enables faster production times, with the ability to assemble up to 50,000 components per hour, reducing time-to-market for electronic products.

- SMT's higher component density and miniaturization capabilities make it ideal for space-constrained applications, such as portable electronics and wearables.

- SMT's automated process minimizes human error, ensuring consistent quality and reducing defect rates, making it a more reliable choice than THT.

Space-Saving Design Advantages

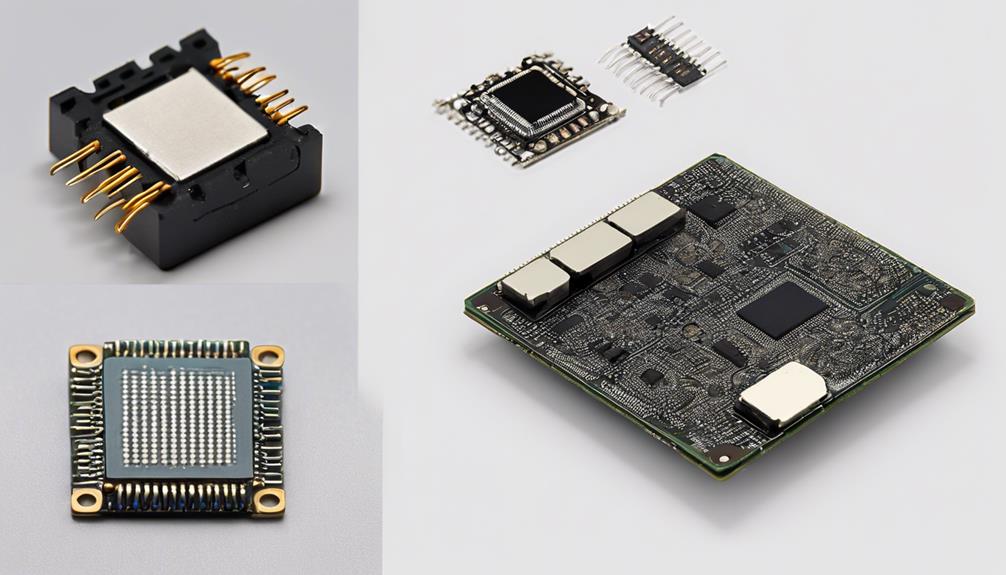

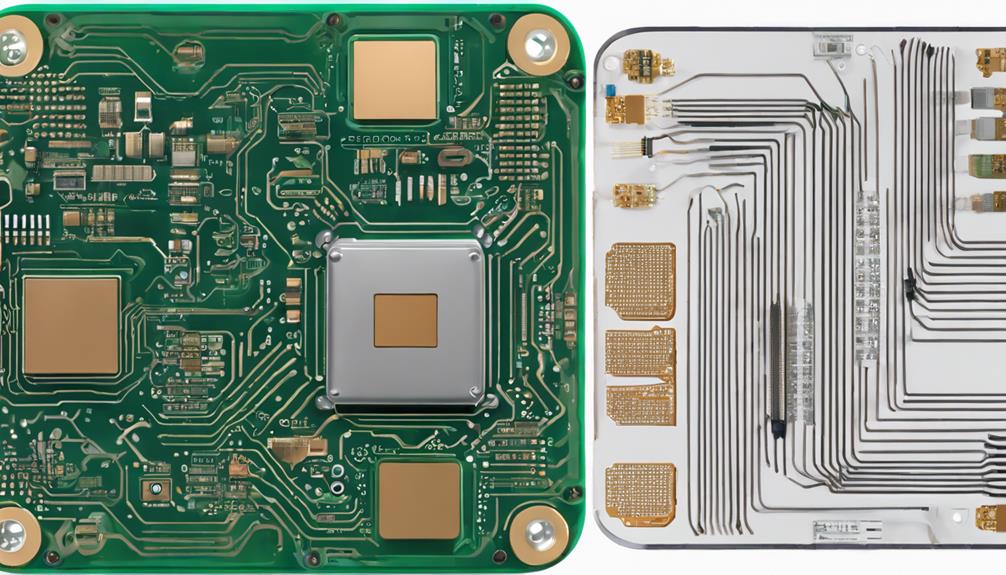

Compact SMT components, which can be up to 75% smaller than their through-hole counterparts, enable designers to create more efficient and space-conscious electronic devices. This space-saving design advantage allows for higher component density on printed circuit boards (PCBs), thereby increasing the overall functionality of the device while reducing its physical footprint.

The elimination of drilled holes in the PCB, a requirement for through-hole technology, further contributes to the space-saving benefits of SMT components. This miniaturization of electronic devices has a direct impact on manufacturing costs, as smaller devices require less material and are more energy-efficient.

The increased component density and space-saving design of SMT components also enable more intricate and advanced circuit designs, pushing the boundaries of what is possible in electronic device development. By leveraging these advantages, designers can create innovative products that are both powerful and compact, setting a new standard for electronic device design.

Faster Production With Automation

Building on the space-saving advantages of SMT components, the incorporation of automation in the production process further accelerates the manufacturing cycle, enabling faster production and improved product quality.

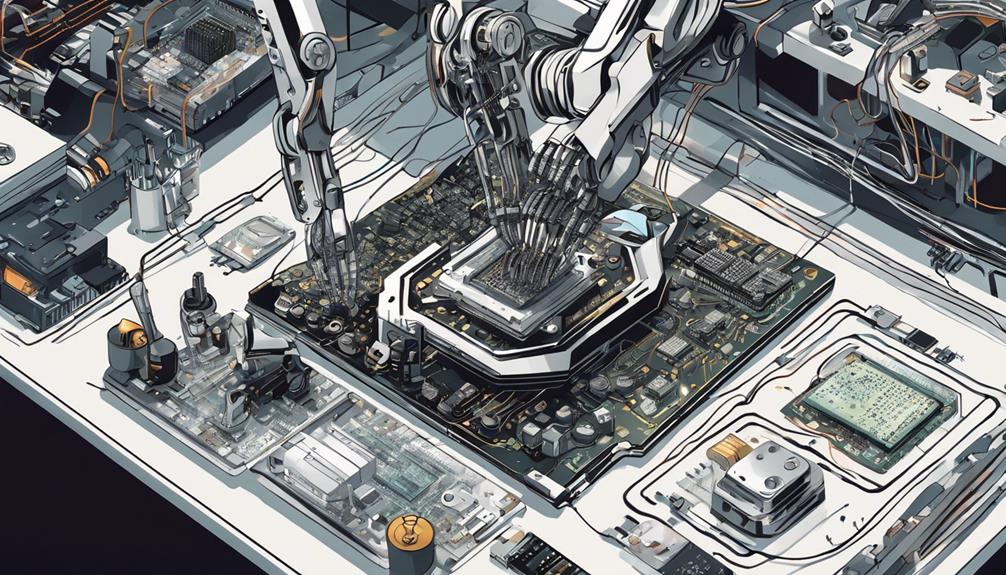

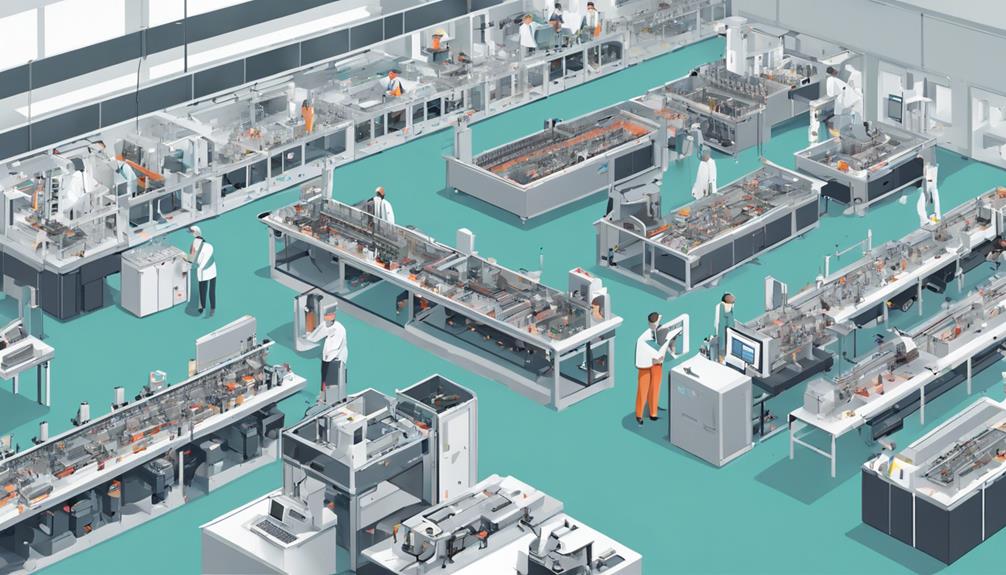

Automation plays a pivotal role in enhancing production efficiency, as it minimizes manual labor and reduces the likelihood of human error. Pick-and-place machines, for instance, accurately place components at high speeds, allowing for rapid production. Additionally, automated inspection systems guarantee higher precision and quickly detect defects, thereby maintaining consistent quality.

The combination of automation and SMT technology enables continuous production runs, minimizing downtime and improving overall productivity. With SMT, high-volume production becomes feasible without compromising quality, making it an attractive option for manufacturers seeking to optimize their production processes.

Lower Manufacturing Costs

In the domain of surface mount technology (SMT), decreasing manufacturing costs is a substantial advantage.

By leveraging the reduced material consumption inherent in SMT components and streamlining the production process through automation, manufacturers can greatly lower their expenses.

This efficient production process, characterized by the minimized use of expensive through-hole components, ultimately leads to a cost-effective solution for high-volume PCB manufacturing.

Reduced Material Consumption

By eliminating the need for drilled holes in PCBs, Surface Mount Technology (SMT) greatly reduces material consumption, leading to lower manufacturing costs. The absence of drilled holes in SMT-based PCBs translates to a significant reduction in material usage. Moreover, SMT components are designed to be smaller and lighter, which further contributes to reduced material consumption.

In contrast, through-hole technology requires more material to accommodate the drilling process, resulting in higher material costs. SMT's surface mounting technology minimizes waste compared to through-hole mounting, ensuring an efficient use of materials. This cost-efficient approach to material usage enables manufacturers to produce high-volume orders at a lower cost.

The reduced processing steps in SMT also contribute to cost efficiency, as fewer processing steps mean less material waste and lower production costs. By leveraging SMT's material-efficient design, manufacturers can optimize their production processes, reducing material consumption and lowering manufacturing costs.

Efficient Production Process

Moreover, the streamlined production process inherent to Surface Mount Technology enables manufacturers to achieve significant reductions in manufacturing costs, primarily due to the automation of assembly processes and the reduced material requirements of surface-mounted components. This efficiency is attributed to the automation of machinery, which reduces labor costs and increases production speeds.

Additionally, the use of surface-mounted components minimizes material consumption, resulting in lower manufacturing expenses. The automation of SMT assembly processes leads to higher throughput and lower overhead expenses compared to THT methods, making it a cost-effective choice for large-scale production.

Moreover, the streamlined production process minimizes the need for additional drilling, resulting in cost savings and quicker turnaround times. Overall, the efficient nature of SMT assembly translates to reduced overall manufacturing expenses, making it an attractive option for manufacturers seeking to optimize their production processes.

Higher Component Density Benefits

Compact electronic devices and complex circuit designs rely heavily on surface mount technology (SMT) to achieve higher component density on printed circuit boards (PCBs). This is made possible by the smaller package sizes and closer placement of components, allowing for more complex circuit designs and miniaturization of electronic devices.

The benefits of higher component density in SMT are numerous:

Increased component density leads to reduced PCB size and weight, making it ideal for compact and lightweight products.

Higher component density in SMT leads to improved electrical performance and signal integrity in high-frequency applications.

SMT's higher component density offers cost savings in production by utilizing smaller, more affordable components efficiently.

The smaller size of SMT components enables more complex circuit designs and miniaturization of electronic devices.

Miniaturization and Size Reduction

Surface mount technology's ability to accommodate higher component density has a direct impact on the miniaturization of electronic devices, enabling the creation of smaller, more efficient products.

This miniaturization is achieved through the use of smaller components, which in turn enables higher component density on the printed circuit board (PCB). The result is a significant reduction in the overall PCB footprint, making it ideal for space-constrained applications.

The smaller package sizes offered by SMT technology contribute to improved thermal management and overall system efficiency. In addition, the compact designs enabled by SMT's miniaturization capabilities make it the preferred choice for portable electronics, wearables, and IoT devices.

By leveraging SMT's size reduction capabilities, designers can create more compact and lightweight products that meet the demands of modern electronics.

Improved Reliability and Yield

When considering reliability and yield, SMT technology inherently offers higher levels and efficiencies compared to traditional through-hole technology by leveraging automated assembly processes and reducing mechanical stress on components. This is accomplished through the elimination of mechanical stress on components, which can result in premature failure. Moreover, the automated assembly processes minimize human error, leading to increased yields.

The advantages of SMT regarding reliability and yield are further emphasized by the following benefits:

- SMT components have better resistance to shock and vibration, enhancing overall product reliability.

- The smaller size and weight of SMT components contribute to improved thermal management and overall system performance.

- SMT's surface mounting eliminates the need for drilled holes, reducing the risk of PCB damage and enhancing manufacturing efficiency.

- SMT assembly yields are generally higher than THT due to automated processes that minimize human error.

Reduced Labor Costs and Time

The adoption of SMT technology greatly reduces labor costs and time, primarily due to the automation of the assembly process. This leads to lower assembly times, efficient production processes, and a reduced operator count.

Lower Assembly Times

Efficiency gains in SMT assembly translate to greatly reduced labor costs and time, yielding a competitive edge in the production of electronic components. This is largely attributed to the automated machinery used in SMT, which enables faster production times and reduces the need for manual labor.

Some key benefits of SMT's lower assembly times include:

- Faster production cycles: With the ability to assemble up to 50,000 components per hour, SMT production cycles are considerably quicker than manual THT assembly.

- Reduced labor costs: By minimizing the need for manual labor, SMT assembly reduces labor costs by up to 60% compared to THT.

- Quicker time-to-market: With faster production cycles, SMT enables electronic products to reach the market faster, giving manufacturers a competitive edge.

- Improved accuracy: SMT's automated process minimizes human error, resulting in higher accuracy and consistency in component placement.

Efficient Production Process

In the pursuit of optimizing electronic component production, Surface Mount Technology (SMT) offers a distinct advantage over Through-Hole Technology (THT) due to its highly efficient production process, which yields notable reductions in labor costs and time. By leveraging automated pick-and-place machines, SMT assembly reduces labor costs by up to 60% compared to THT, allowing for substantial savings.

Moreover, SMT production is considerably faster, with cycle times up to 5 times quicker than THT assembly processes. Automated SMT lines can achieve placement rates of over 30,000 components per hour, enhancing production efficiency.

The streamlined manufacturing process, which allows for simultaneous soldering of multiple components, also contributes to lower error rates and higher production yields compared to THT methods. This efficient production process, enabled by SMT technology, results in faster production times, reduced labor costs, and improved overall production quality.

Reduced Operator Count

By minimizing the need for human intervention, Surface Mount Technology (SMT) reduces operator count by up to 90% compared to Through-Hole Technology (THT), resulting in substantial labor cost savings and accelerated production timelines.

This significant reduction in operator count is made possible by the automation capabilities of SMT. Automated machinery handles component placement, soldering, and inspection tasks, minimizing manual labor requirements. The reduced need for manual labor in SMT assembly translates to faster production times and quicker turnaround for projects.

Some key benefits of SMT's reduced operator count include:

- Automated machinery: Robotic pick-and-place machines and automated soldering equipment promote high efficiency in component mounting.

- Labor cost savings: With fewer operators required, SMT assembly results in significant labor cost savings.

- Production consistency: SMT's automation capabilities enhance overall production consistency and quality control.

- Accelerated production timelines: By minimizing manual labor, SMT enables faster production times and quicker project turnaround.

Is SMT Assembly More Efficient and Effective for High-Performance Electronics Than Through-Hole Assembly?

When it comes to high-performance electronics, SMT assembly offers a more efficient and effective solution compared to reliable throughhole assembly. The smaller components and higher density of SMT technology allow for faster processing and improved performance, making it the preferred choice for cutting-edge electronics.

Enhanced Design Flexibility Options

Compact designs are made possible with SMT, as the absence of holes on the printed circuit board (PCB) allows for a more flexible and efficient use of space. This, in turn, enables designers to create innovative and compact designs that cater to modern electronics' needs, such as miniaturization and high-speed operations.

SMT components offer higher circuit density, allowing for more functionality in limited space, which is especially vital in today's compact and powerful devices. Designers have more flexibility with SMT layouts, optimizing for performance and space efficiency. This flexibility is further enhanced by the ability to automate assembly processes, reducing production time and costs.

The culmination of these advantages is a significant enhancement in design flexibility, allowing designers to push the boundaries of innovation and creativity. By leveraging SMT technology, designers can create cutting-edge electronics that deliver exceptional performance and meet the ever-growing demands of the industry.

Frequently Asked Questions

Why Is Surface Mount Technology Beneficial Over Through Hole Technology?

In addition, Surface Mount Technology (SMT) offers distinct advantages over Through Hole Technology (THT).

By enabling higher component density and smaller package sizes, SMT facilitates more compact and lightweight PCB designs.

Moreover, SMT's automated assembly processes are faster and more cost-effective, resulting in reduced production costs.

Additionally, SMT components are generally cheaper due to their smaller size and high-volume production capabilities, making it a more economical option.

What Is the Main Difference Between THT and SMD Ics?

Notably, over 80% of modern electronic devices rely on Surface Mount Technology (SMT). The main difference between THT (Through-Hole Technology) and SMD (Surface Mount Device) ICs lies in their mounting methods.

SMD ICs are mounted directly onto the PCB surface, eliminating the need for drilled holes, whereas THT ICs have leads that pass through holes on the board. This fundamental difference has a substantial impact on PCB design, assembly, and overall production efficiency.

Which Statement Gives the Advantage of Using SMT Components?

When considering the advantages of Surface Mount Technology (SMT) components, the statement that highlights their benefit is: 'SMT components offer higher component density and smaller package sizes.'

This characteristic enables more compact designs, increased functionality, and improved performance in electronic devices.

The smaller size and higher density of SMT components make them an attractive choice for modern electronics, driving innovation and advancement in the industry.

Is Surface Mount Cheaper Than Through-Hole?

Surface mount technology (SMT) is indeed cheaper than through-hole technology (THT).

The primary cost advantage of SMT stems from reduced material usage and faster assembly processes. Additionally, smaller and lighter SMT components result in lower material and shipping expenses.

Automated SMT assembly further increases efficiency and reduces labor costs, making it a more cost-effective option, particularly in large-scale production runs.