Through-hole assembly guarantees a reliable choice for high-performance electronics, delivering durable and secure connections in demanding environments and high-stress applications. This traditional technology offers enhanced durability, resistance to environmental stress, and reliable connections, making it ideal for aerospace, defense, and other high-reliability industries. By combining ruggedized component selection, vibration-resistant bonding methods, and stringent quality standards, through-hole assembly assures reliable performance under extreme conditions. As you explore the nuances of through-hole assembly, discover how this tried-and-tested technology can elevate the performance of your high-performance electronics.

Key Takeaways

- Through-hole assembly provides durable and secure connections, ideal for high-performance electronics in demanding environments.

- Ruggedized component selection and vibration-resistant bonding methods ensure enhanced durability in high-stress applications.

- Certified experts utilize cutting-edge soldering methods to guarantee precise and reliable connections in high-reliability industries.

- Through-hole technology combines with modern quality control practices to set a new standard for high-performance electronics assemblies.

- Mechanically anchored connections and robust bonding methods ensure superior longevity and reliability in harsh environments.

Through-Hole Technology Applications

In high-reliability industries, such as aerospace and defense, Through-Hole technology is a preferred choice for its ability to deliver durable and secure connections in demanding environments. This technology is particularly suited for high-stress applications where component failure is not an option. Through-Hole PCB Assembly is ideal for components requiring high reliability and durability in harsh environments, making it a staple in industries where performance and reliability are paramount.

Through-Hole technology is well-suited for high-power and high-voltage components due to its robust connections, strengthening the bonds between components and the printed circuit board (PCB). This results in secure connections that can withstand the rigors of high-stress applications.

The technology's ability to deliver reliable connections in demanding environments makes it an essential component in the development of high-performance electronics. By leveraging Through-Hole technology, manufacturers can create robust and reliable systems that perform effectively in even the most challenging conditions.

High-Reliability PCB Assembly Benefits

The benefits of High-Reliability PCB Assembly, rooted in Through-Hole technology, lie in its ability to provide enhanced durability and reliability, making it an essential component in the development of high-performance electronics.

This is achieved through the creation of stronger bonds between components and the board, ensuring secure connections. The leads in Through-Hole components connect two locations on a circuit board, further reinforcing the reliability of the assembly.

The technology's resistance to environmental stress makes it highly reliable for high-power and voltage components, making it an ideal choice for high-stress applications. The aerospace and defense industries, in particular, prefer Through-Hole technology due to its exceptional reliability and durability.

Through-Hole PCB Assembly provides increased reliability, making it suitable for prototypes and full production runs. By leveraging the benefits of Through-Hole technology, manufacturers can develop high-performance electronics that meet the demands of high-stress applications, ensuring excellent performance and reliability.

Enhanced Durability for Demanding Environments

In demanding environments, through-hole assembly's enhanced durability is achieved through the strategic selection of ruggedized components, vibration-resistant bonding methods, and corrosion-proof material choices. These carefully considered design elements guarantee reliable performance under extreme conditions, making through-hole technology an ideal choice for high-reliability applications.

Ruggedized Component Selection

Ruggedized component selection is pivotal in ensuring the reliability and durability of high-performance electronics. It enables the development of robust systems capable of withstanding extreme temperatures, vibrations, and other environmental stresses.

Through-hole components are particularly well-suited for demanding applications. They are mechanically anchored to printed circuit boards (PCBs), making them more robust and resistant to mechanical stress. This anchoring provides secure connections, reducing the likelihood of damage and failure under harsh conditions.

As a result, through-hole components are less prone to failure, ensuring higher reliability and durability in rugged environments. This makes them ideal for high-stress applications in industries like aerospace and defense, where durability is paramount.

Vibration-Resistant Bonding Methods

Vibration-resistant bonding methods are essential in guaranteeing the long-term reliability of high-performance electronics, particularly in environments prone to intense mechanical stresses, where robust connections are paramount. Through-hole assembly techniques provide enhanced durability by securing components against vibration-related issues. Leads inserted through drilled holes form strong bonds, ideal for applications prone to mechanical stresses. Components soldered to PCBs offer reliable connections resistant to vibration-induced failures.

| Bonding Method | Advantages | Applications |

|---|---|---|

| Through-Hole Assembly | Enhanced durability, robust connections | Aerospace, Automotive, Industrial |

| Soldering | Reliable connections, resistance to vibration-induced failures | High-Vibration Environments, Demanding Applications |

| Mechanically Anchored Components | Resistance to mechanical stresses, enhanced durability | High-Performance Electronics, Ruggedized Applications |

Designed for demanding environments, through-hole bonding methods ensure long-term reliability in high-performance electronics. By leveraging the strengths of through-hole assembly, engineers can create reliable and durable PCB assemblies, capable of withstanding intense mechanical stresses and vibrations.

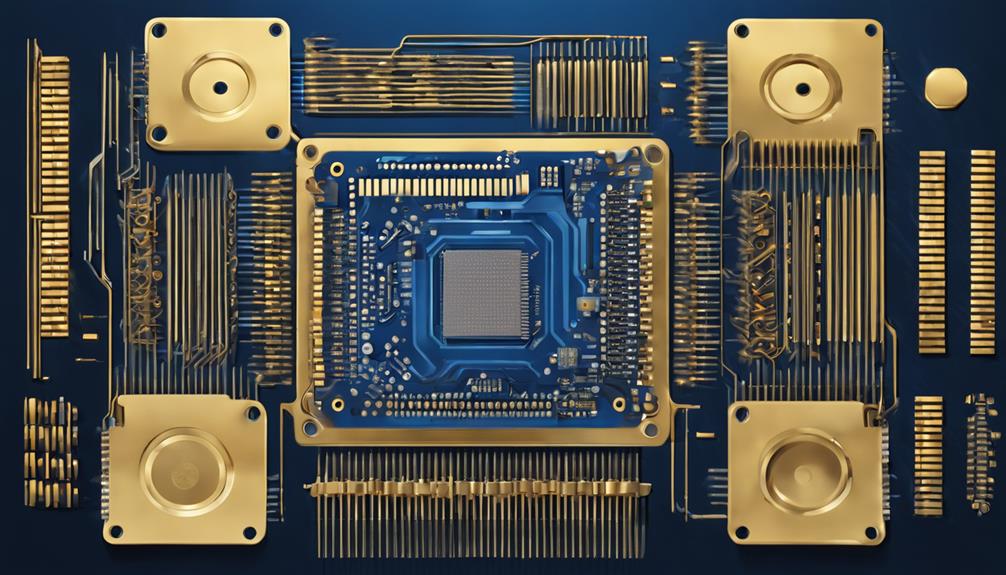

Corrosion-Proof Material Choices

Corrosion-proof material choices play a pivotal role in guaranteeing the long-term reliability of high-performance electronics, particularly in environments prone to moisture, humidity, and chemical exposure. The selection of corrosion-resistant materials is crucial to prevent component failure and ensure peak performance.

To achieve enhanced durability, consider the following corrosion-proof material options:

- Gold-plated leads for superior resistance to corrosion and oxidation.

- Nickel-plated components for excellent protection against environmental factors like humidity and chemicals.

- Tin-lead alloys for reliable protection against moisture, humidity, and chemical exposure.

In addition to these materials, applying conformal coatings like acrylic or silicone can further safeguard against corrosion and environmental damage.

Silver immersion finish on through-hole components also ensures long-term performance in harsh conditions. By selecting the right corrosion-proof materials and applying protective coatings, high-performance electronics can withstand demanding environments and maintain peak performance over an extended lifespan.

Robust Connections for Critical Systems

In high-reliability applications, such as aerospace and defense systems, the integrity of electrical connections is crucial, and Through-Hole Assembly plays a pivotal role in guaranteeing the dependability of critical systems.

The robust connections created through this process are essential for maintaining system performance and preventing component failure. By inserting leads through drilled holes on printed circuit boards (PCBs), Through-Hole Assembly creates strong, durable connections that can withstand mechanical stress and harsh environmental conditions. This makes it an ideal choice for applications where reliability is paramount.

The versatility of Through-Hole Assembly also allows for the accommodation of various component types and sizes on the same board, providing designers with greater flexibility. In high-performance electronics, the reliability of Through-Hole Assembly ensures that critical systems operate consistently and efficiently, even in the most demanding environments.

Industry-Leading Through-Hole Expertise

Leading industry players, such as PCBTok, Aimtron, and Profab Electronics, have established themselves as authorities in Through-Hole Assembly, leveraging their expertise to deliver high-quality solutions that meet the stringent demands of high-performance electronics.

These industry leaders have achieved exceptional quality standards, with certifications such as AS9100D and ISO 9001, ensuring precision and reliability in their through-hole assembly services. Their advanced soldering techniques, including wave soldering and robotic soldering, guarantee precise and reliable connections.

Here are three key benefits of partnering with industry-leading through-hole assembly experts:

- Unparalleled quality: Certified to stringent quality standards, ensuring reliability and precision in every assembly.

- Advanced techniques: Utilizing cutting-edge soldering methods for robust and durable connections.

- Proven expertise: Decades of experience in delivering high-performance through-hole assembly solutions for critical applications.

Proven Track Record of Success

Through-Hole Assembly has consistently demonstrated a proven performance history, with a long-standing reputation for delivering high-quality electronic assemblies that meet the most stringent requirements.

This consistent quality delivery is a direct result of the technology's ability to guarantee secure connections and longevity in demanding environments.

Proven Performance History

With a legacy of dependability, Through-Hole Assembly has consistently demonstrated its ability to deliver high-reliability connections in demanding environments. This technology has a proven track record of success in high-stress applications, such as aerospace and defense, where failure is not an option.

Through-Hole technology has reliably connected circuits in demanding environments for many years, and its longevity and availability make it a dependable choice for industrial equipment.

Here are just a few examples of its proven performance history:

- Reliable performance in extreme conditions: Through-Hole Assembly has a history of providing secure connections and high reliability in extreme temperatures, vibrations, and other environmental stressors.

- Durability under mechanical stress: Through-Hole technology is known for its durability and resistance to mechanical stresses, ensuring reliable performance even in the most challenging applications.

- Long-term availability and support: With a long history of use and a wide range of available components, Through-Hole Assembly offers a reliable and sustainable solution for high-performance electronics.

Consistent Quality Delivery

Building on its legacy of reliability, Profab Electronics reinforces its commitment to delivering consistent quality through-hole PCB assembly services, backed by a proven track record of success. This commitment is underpinned by stringent quality assurance processes, which guarantee reliable connections and durable performances in high-performance electronics.

With ISO 9001, AS9100, and ITAR certifications, Profab Electronics maintains industry-leading standards in PCB assembly, ensuring customers receive top-tier through-hole assembly solutions.

Profab Electronics' hybrid assembly process combines traditional through-hole technology with modern practices, enhancing performance and reliability. This unique approach enables the company to deliver versatile and reliable through-hole assembly solutions across various industries.

Meeting Stringent Quality Standards

Consistently, Profab Electronics adheres to exacting quality standards in its Through-Hole Assembly services, guaranteeing that every PCB meets the most stringent industry regulations. This commitment to quality is reflected in our certifications, including ISO 9001, AS9100, and ITAR, which demonstrate our dedication to delivering high-performance electronics.

To assure the reliability and durability of our components, we prioritize stringent quality assurance processes in our manufacturing practices. Each PCB undergoes meticulous inspection and testing to confirm compliance with industry standards.

Here are just a few ways we meet stringent quality standards:

- Rigorous testing and inspection: Every PCB is thoroughly tested and inspected to confirm it meets the highest quality standards.

- Adherence to industry regulations: We comply with ISO 9001, AS9100, and ITAR regulations, guaranteeing our Through-Hole Assembly services meet the most stringent industry standards.

- Prioritizing quality in every step: From component selection to final assembly, we prioritize quality assurance processes to ensure our Through-Hole Assembly services deliver exceptional performance.

Component Assembly for Harsh Conditions

Operating in harsh environments, high-reliability electronics demand robust assembly solutions that can withstand extreme temperatures, vibration, and mechanical stress. Through-Hole assembly is a dependable option for component integration in high-reliability sectors, such as aerospace, where components are exposed to challenging operating conditions. This adaptable technology is suited to different component types and sizes, offering flexibility in design.

| Characteristics | Benefits |

|---|---|

| Robust connections | Withstands mechanical stress and harsh environments |

| Versatile technology | Adaptable to different component types and sizes |

| Hybrid assembly solutions | Combines Through-Hole with Surface Mount Technology for greater design flexibility |

| Stringent quality assurance | Guarantees compliance with industry standards and regulations |

Through-Hole assembly creates robust connections suitable for components exposed to mechanical stress or harsh environments. By integrating Through-Hole with Surface Mount Technology, hybrid assembly solutions can be achieved, offering greater design flexibility and component integration. Stringent quality assurance processes guarantee compliance with industry standards, such as ISO 9001, AS9100, and ITAR regulations, resulting in durable and reliable PCB assembly.

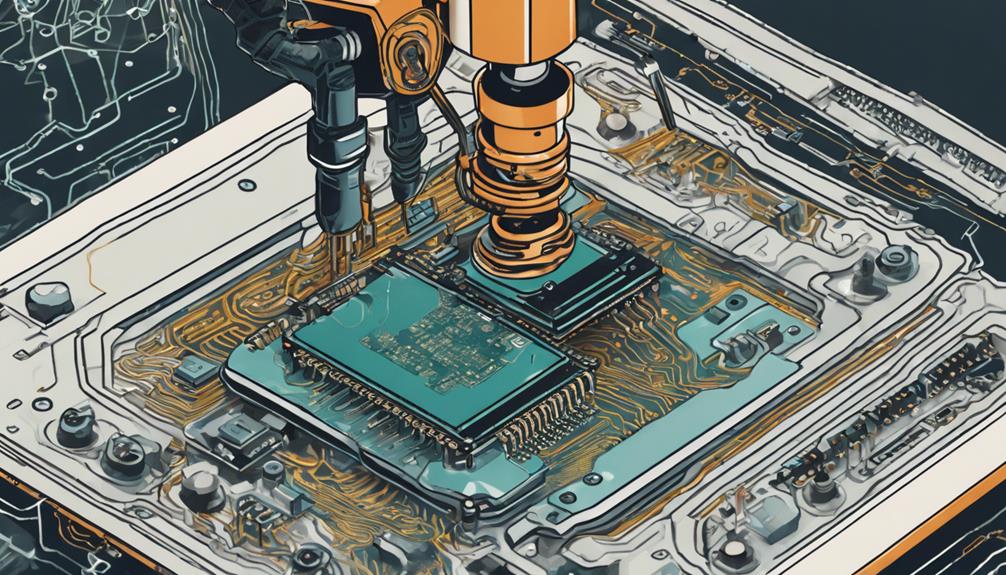

Traditional Technology With Modern Twist

The integration of traditional Through-Hole technology with modern practices enables a robust assembly process that combines the benefits of both worlds.

This hybrid approach allows for the incorporation of advanced quality control measures, ensuring the production of high-reliability electronics.

Modernized Manufacturing Process

Profab Electronics' modernized manufacturing process seamlessly integrates traditional Through-Hole technology with modern practices to achieve enhanced reliability and versatility in high-performance electronics. By combining the strengths of Through-Hole technology with the flexibility of Surface Mount Technology, our hybrid assembly process enables the integration of a wide range of components. This approach allows us to create highly reliable and durable electronic assemblies that thrive in high-stress environments.

Here are three key benefits of our modernized manufacturing process:

- Enhanced Reliability: Through-Hole technology creates strong, durable connections that withstand harsh environments.

- Increased Flexibility: Our hybrid assembly process integrates a wide range of components, ensuring versatility in design and application.

- Unparalleled Quality: Our stringent quality assurance processes guarantee compliance with ISO 9001, AS9100, and ITAR regulations, ensuring the highest level of quality and reliability.

Advanced Quality Control

By combining traditional Through-Hole technology with modern quality control methodologies, Profab Electronics guarantees that its high-performance electronics assemblies meet the most stringent standards of reliability and compliance.

This advanced quality control process assures that every Through-Hole assembly surpasses industry benchmarks, adhering to rigorous ISO 9001, AS9100, and ITAR regulations. Profab Electronics' meticulous inspection and testing procedures ensure durable and compliant PCB assembly services, providing customers with unwavering confidence in their products.

The hybrid assembly process at Profab Electronics offers greater design flexibility and component integration options, further enhancing the reliability of the final product. By marrying traditional Through-Hole technology with modern quality control practices, Profab Electronics sets a new standard for high-performance electronics assemblies.

This synergy of traditional and modern approaches enables the company to deliver exceptional quality and reliability, making it the go-to partner for demanding applications.

How Can Through-Hole Assembly and SMT Component Placement Improve Electronics Performance?

Through-hole assembly and SMT component placement play a vital role in optimizing small circuits placement. By carefully positioning and soldering components, electronics performance can be greatly enhanced. This method allows for better signal integrity, reduced electrical noise, and overall improved functionality of electronic devices.

Reliable Connections for High-Performance

Durability is paramount in high-performance electronics, where reliable connections are critical to guaranteeing the integrity of the entire system. Through-hole assembly is a preferred method for creating durable connections in high-performance electronics, as it involves inserting component leads through drilled holes on the printed circuit board (PCB). This approach guarantees reliable bonds between components and the board, making it ideal for high-performance applications.

The benefits of through-hole assembly include:

- Mechanically anchored connections, providing enhanced durability for high-stress applications.

- Superior longevity and reliability, even in demanding environments.

- Robustness and reliability, making it a preferred choice in industries like aerospace and defense.

Frequently Asked Questions

What Are the Disadvantages of Through-Hole Components?

The use of through-hole components presents several disadvantages. To begin with, their larger physical size and spacing requirements can limit component density on a printed circuit board (PCB).

Manual insertion and soldering are time-consuming and labor-intensive, impacting production efficiency. Moreover, through-hole components may require mechanical support, adding complexity to the assembly process.

Additionally, the through-hole plating process is more susceptible to defects, and repairing or replacing these components can be challenging and costly.

What Are the Advantages of Through-Hole Technology?

Through-hole technology offers several advantages, particularly in high-stress applications. It provides robust bonds between components and PCBs, ensuring durability and reliability.

Through-hole components can handle high power and voltage levels, making them ideal for demanding applications. Additionally, this technology facilitates easier prototyping and testing, enabling quicker design iterations and troubleshooting.

What Are the Two Types of Through-Hole Components?

In the domain of Through-Hole technology, an important distinction lies in the two primary types of components: radial lead and axial lead. The former features leads emerging from the component body, while the latter boasts leads extending from each end.

This fundamental difference has significant implications for PCB assembly, as radial lead components are soldered directly into holes, whereas axial lead components require insertion and soldering on both sides.

What Is Through-Hole Assembly?

Through-hole assembly is a method of mounting electronic components on a printed circuit board (PCB) by inserting leads through pre-drilled holes, creating a strong mechanical bond.

This assembly technique enables reliable connections, ensuring durability and longevity in high-performance applications.