When selecting a surface mount technology (SMT) component placement machine, partnering with top manufacturers like Yamaha Motor, Fuji Corporation, Panasonic, and DDM Novastar guarantees access to advanced technology, precision, and speed. These industry leaders prioritize precise alignment, high-speed placement, and consistent component positioning, resulting in efficient PCB assembly, high-quality electronic devices, and reduced errors. By choosing a top SMT machine maker, manufacturers can optimize their production process, improve accuracy, and increase productivity. To discover the full range of benefits and features that top SMT machine makers provide, explore further to uncover the advantages of precision component placement.

Key Takeaways

- Partnering with top SMT machine makers grants access to cutting-edge equipment, a wide range of machine options, and after-sales support.

- Advanced technology and precision enable high-speed component placement, meeting high-volume demands and optimizing production processes.

- Leading manufacturers prioritize precise alignment, high-precision component placement, and advanced vision systems for accurate chip alignment.

- Expert support and dedicated technical assistance ensure seamless operations, rapid response guarantees, and peak performance.

- Top SMT machine makers offer machines tailored to diverse production needs and budgets, supporting a wide range of component types, sizes, and PCB layouts.

Top SMT Machine Manufacturers Matter

What sets top SMT machine manufacturers apart is their unwavering commitment to delivering high-performance machines that consistently meet the stringent demands of modern electronic assembly. Top manufacturers like Yamaha Motor, Fuji Corporation, Panasonic, and DDM Novastar have earned their reputation by providing reliable and efficient SMT machines that streamline component placement and PCB assembly processes.

These top SMT machine manufacturers are distinguished by their advanced technology, precision, and speed in component placement, ensuring efficient production outcomes. By partnering with these industry leaders, electronic assembly companies can access cutting-edge equipment, expertise, and after-sales support, guaranteeing excellent production results.

Additionally, top SMT machine manufacturers offer a wide range of machine options to cater to diverse production volumes, component types, and budget requirements. By choosing a top SMT machine manufacturer, electronic assembly companies can maintain industry-standard quality, performance, and durability in their electronic assembly processes.

Precision Component Placement Matters

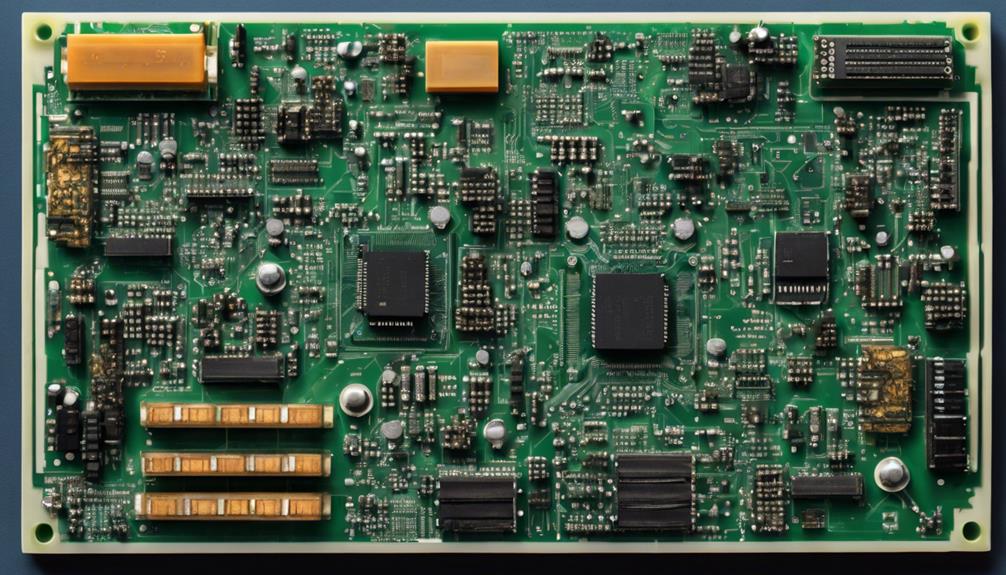

In precision component placement, accurate chip alignment is vital, as it guarantees that electronic components are positioned correctly on the printed circuit board (PCB).

High-speed placement capability is also essential, as it enables manufacturers to meet production demands while maintaining precision.

Consistent component positioning is equally important, as it reduces the risk of defects and improves overall product quality.

Accurate Chip Alignment

High-precision alignment of surface-mount technology (SMT) components is essential for the best performance and reliability of electronic devices, as even slight misalignments can compromise the entire assembly. Top SMT component placement machine makers understand the importance of precise alignment, guaranteeing that components are accurately placed on printed circuit boards (PCBs). This precision is achieved through advanced vision systems that enable accurate chip alignment, minimizing errors and ensuring excellent product quality.

Accurate chip alignment is critical in SMT component placement, as it ensures efficient PCB assembly and reliable electronic devices. Leading SMT machine manufacturers provide high-precision component placement capabilities, ensuring that components are placed with exactness and precision.

This precise alignment ensures that electronic devices function as intended, with excellent performance and reliability. By choosing top SMT machine makers, manufacturers can secure precise alignment of components, resulting in high-quality electronic devices that meet the desired standards.

High-Speed Placement Capability

Among the key differentiators of top SMT component placement machine makers is their ability to achieve remarkably high placement speeds, with market leaders like Yamaha capable of reaching rates of up to 200,000 components per hour. This high-speed placement capability is critical in precision component placement, where accuracy is paramount.

Advanced vision systems on top SMT machines guarantee precise component alignment and orientation during high-speed placement, allowing for consistent and reliable production. By reducing production time and costs, top SMT machines are ideal for large volume PCB assembly. Top manufacturers prioritize reliability, repeatability, and efficiency in component placement to meet the demands of modern electronics manufacturing.

With precision component placement down to 25 microns, top SMT machines deliver unparalleled accuracy and speed. By leveraging high-speed placement rates, manufacturers can significantly lower production time and costs, making top SMT component placement machines the ideal choice for high-volume electronics production.

Consistent Component Positioning

Top-tier SMT component placement machine makers prioritize consistent component positioning, leveraging advanced technologies to guarantee precise placement that is essential for ideal electronic device functionality and reliability.

Consistent component positioning is paramount in guaranteeing the reliability and performance of electronic devices. Leading SMT machine manufacturers employ high-precision technologies to achieve accurate and repeatable component placement, minimizing errors and rework. This precision component placement capability enables the production of high-quality electronic devices with increased reliability and reduced defects.

By choosing top SMT component placement machine makers, manufacturers can ensure reliable and high-quality assembly processes, resulting in enhanced production efficiency and reduced costs. With consistent component positioning, electronic devices can operate at peak levels, delivering superior performance and longevity.

Top SMT machine makers guarantee high-precision component placement, enabling the creation of advanced electronic devices that meet the most stringent quality and reliability standards.

Benefits of Advanced SMT Machines

Advanced SMT machines offer a range of benefits to the PCB assembly process. These include increased production efficiency, improved accuracy rates, and enhanced component flexibility.

These advantages enable manufacturers to streamline their operations, reduce errors, and cater to diverse production needs. By leveraging these benefits, manufacturers can optimize their production workflows and improve overall productivity.

Increased Production Efficiency

By leveraging high-speed component placement capabilities, top SMT component placement machines greatly enhance production efficiency, thereby enabling manufacturers to meet high-volume demands and optimize their production processes.

These advanced machines guarantee precise and accurate component placements, reducing errors and rework in the assembly process. As a result, manufacturers can achieve improved throughput rates, enabling faster production cycles and meeting high-volume demands.

Leading SMT machine makers offer cutting-edge technology and features that enhance overall production efficiency and quality. By investing in top SMT component placement machines, manufacturers can experience cost savings through optimized production processes and reduced downtime. This, in turn, enables them to respond promptly to changing market demands and stay ahead of the competition.

With SMT machines used in production, manufacturers can streamline their operations, reduce waste, and increase productivity. By choosing top SMT component placement machine makers, manufacturers can reap the benefits of advanced machines, high-speed component placement, and improved production efficiency.

Improved Accuracy Rates

High-precision component placement is a hallmark of advanced SMT machines, which achieve accuracy rates of up to 50,000 components per hour, guaranteeing reliable and consistent electronic assemblies. This level of precision is made possible by the incorporation of advanced vision systems, which enable precise component placement within microns.

As a result, top SMT machine makers offer improved accuracy rates, leading to reduced errors and rework, saving time and costs in production.

The benefits of advanced SMT machines are numerous and include:

- Enhanced precision: Precise component placement guarantees high-quality PCB assembly

- Reduced errors: Improved accuracy rates lead to fewer errors and rework

- Increased reliability: Consistent electronic assemblies are guaranteed through precise component placement

- Cost savings: Reduced errors and rework result in time and cost savings in production

Enhanced Component Flexibility

With the ability to accommodate a wide range of components on various PCB sizes, top SMT machine makers offer unparalleled flexibility in component placement. Advanced SMT machines are designed to handle diverse component types, including fine-pitch, BGA, and QFN, with high precision and accuracy.

This enhanced component flexibility is made possible through advanced features such as vision systems and intelligent feeders, which enable seamless component placement. As a result, production efficiency is improved, errors are reduced, and overall quality in PCB assembly is increased.

Investing in top SMT machine makers also guarantees compatibility with future component advancements, making your assembly process future-proof. By leveraging the capabilities of advanced SMT machines, manufacturers can stay ahead of the curve and capitalize on emerging trends in electronics production.

With enhanced component flexibility, manufacturers can respond quickly to changing market demands, ensuring a competitive edge in the industry.

High-Speed Component Placement

Achieving fast component placement rates is essential in modern surface-mount technology (SMT) assembly, as it directly impacts production efficiency and turnaround times. Top SMT component placement machine makers understand this requirement and offer high-speed machines capable of placing components at rates exceeding 100,000 components per hour. These machines utilize advanced technologies like vision systems and robotic arms to achieve precise and rapid component placement.

The benefits of high-speed component placement include:

Efficient production processes and quicker turnaround times for PCB assembly

Enhanced productivity, accuracy, and overall production efficiency

Ability to meet the demands of high-volume production environments

Precision component placement, ensuring reliable and high-quality PCB assemblies

Consistency in PCB Assembly

Consistency in PCB assembly is paramount for ensuring reliable production processes and high-quality products. Top SMT component placement machine makers prioritize precise component placement, achieving accuracy within 0.001 inches to minimize errors and guarantee consistent results.

Precise Component Placement

Accurate component placement is paramount in PCB assembly, as it directly impacts the reliability and performance of the final electronic product. Top SMT machine makers understand the importance of precision in component placement, guaranteeing consistent and accurate assembly of PCBs. Their machines are equipped with advanced vision systems and software that facilitate ideal component alignment and placement.

Some key benefits of precise component placement include:

- Enhanced reliability: Precise component placement minimizes the risk of errors and ensures that electronic components function as intended.

- Improved performance: Accurate component placement enables excellent performance of the final electronic product, ensuring that it meets the required specifications.

- Increased efficiency: Precise component placement streamlines the PCB assembly process, reducing the need for rework and minimizing production downtime.

- Consistent quality: High-quality SMT machines from top makers ensure reliable and repeatable component placement, ensuring consistent quality and performance in PCB assembly.

Reliable Production Process

By guaranteeing precise component placement, top SMT component placement machine makers establish a foundation for reliable production processes that consistently yield high-quality PCB assemblies. These machines offer high accuracy in component placement, reducing errors and improving overall product quality.

Leading SMT machine manufacturers prioritize precision and repeatability to maintain consistent assembly results. This focus on precision enables companies to achieve efficient and streamlined production processes, resulting in increased production yields and minimized rework.

Top SMT machine makers understand the importance of a reliable production process, and their machines are designed to deliver consistent assembly results. By selecting a top SMT component placement machine, companies can optimize their manufacturing operations and ensure consistent PCB assembly quality.

With high accuracy and repeatability, these machines provide a solid foundation for reliable production processes that meet the demands of today's fast-paced electronics manufacturing industry.

Advanced SMT Machine Features

Today's SMT component placement machines boast an array of advanced features that enable high-precision, high-speed, and highly flexible PCB assembly processes.

Top SMT component placement machine makers offer machines equipped with cutting-edge technologies that guarantee efficient and accurate production. Some of the key features of these advanced machines include:

- Advanced vision systems for precise component alignment and placement, guaranteeing high-quality PCB assembly.

- User-friendly interfaces and software for efficient programming and operation, reducing production downtime and increasing productivity.

- Dual-gantry systems that enhance productivity and throughput, allowing for faster and more efficient PCB assembly.

- Flexibility to handle a wide range of component sizes and types, ensuring versatility in PCB assembly processes.

These advanced features enable top SMT component placement machine makers to provide machines that meet the demanding requirements of modern PCB assembly.

Expert Support for SMT Machines

Leading SMT machine manufacturers prioritize expert support, guaranteeing seamless operations and minimal downtime. This commitment is evident in their rapid response guarantees, which secure prompt technical assistance in the event of an issue.

Dedicated technical teams provide extensive support, empowering operators to maximize machine efficiency and optimize production workflows.

Rapid Response Guarantee

Among the key benefits offered by top SMT component placement machine makers is a rapid response guarantee, which provides assurance that expert support is always readily available to minimize downtime and maximize machine efficiency.

This guarantee provides confidence to users of SMT component placement machines that they can quickly resolve any issues that may arise, minimizing production delays and maximizing productivity. With a rapid response guarantee, users can have assurance that they will receive prompt and effective support whenever it is needed.

Some of the key features of a rapid response guarantee include:

- 24/7 technical assistance to maintain continuous operation of SMT machines

- On-site training and troubleshooting to optimize machine efficiency

- Global network of service centers for immediate assistance

- Warranty coverage and maintenance plans to reduce downtime and production delays

Dedicated Technical Assistance

Through dedicated technical assistance, top SMT machine makers like Yamaha Motor and Fuji Corporation provide expert support to guarantee peak performance and minimize downtime in PCB assembly processes. This thorough support encompasses troubleshooting, maintenance, and training on how to optimize SMT machine performance. By offering online resources, manuals, and on-site assistance, manufacturers secure smooth operation of SMT machines and facilitate rapid issue resolution.

Access to knowledgeable technicians and engineers enables prompt troubleshooting and efficient maintenance, thereby minimizing production downtime. Moreover, training programs provided by top SMT machine makers empower operators to maximize machine productivity and reliability. By leveraging technical assistance from industry leaders, manufacturers can ensure maximum productivity and reliability in PCB assembly processes.

With dedicated technical support, manufacturers can focus on what matters most – delivering high-quality products efficiently and effectively.

Optimizing PCB Assembly Process

How can manufacturers guarantee that their PCB assembly process operates at peak efficiency, minimizing errors and maximizing productivity?

By partnering with top SMT component placement machine makers, manufacturers can optimize their PCB assembly process. These machines offer advanced features such as high-speed placement, high accuracy, and versatility to handle various component types and PCB sizes efficiently.

- High-speed placement capabilities enable rapid assembly of complex PCBs, reducing production time and increasing output.

- Advanced features, such as component tracking and automated inspection, minimize errors and guarantee high-quality assemblies.

- Versatility in handling various component types and PCB sizes allows for efficient production of diverse product lines.

- Real-time monitoring and data analytics enable manufacturers to track production efficiency and make data-driven decisions to optimize their PCB assembly process.

SMT Machine Quality Control

Precise component placement accuracy, a critical aspect of PCB assembly, hinges on rigorous SMT machine quality control measures. Leading SMT machine makers prioritize quality control to meet industry standards, ensuring reliable and consistent operation for PCB assembly.

To achieve this, SMT machines undergo rigorous quality checks, including machine calibration, inspection, and testing procedures. These measures guarantee that the machines can accurately place components, resulting in high-quality PCBs.

Machine calibration is an essential step in SMT machine quality control, as it ensures that the machine's mechanical and electrical systems are functioning accurately. Inspection and testing procedures are also vital, as they identify any defects or errors that may affect component placement accuracy.

By implementing these quality control measures, top SMT machine makers can guarantee that their machines consistently deliver high-precision component placement, resulting in reliable and efficient PCB assembly.

Flexibility in SMT Machines

Offering a range of machines tailored to diverse production needs and budgets, top SMT machine makers provide flexibility in handling various component types, sizes, and PCB layouts. This flexibility is essential in modern electronics manufacturing, where production lines need to adapt to changing product designs and production volumes.

Top SMT machine makers achieve this flexibility through innovative design and advanced features, including:

- Support for a wide range of component types, including small chips, BGAs, and QFNs

- Ability to handle various PCB sizes and layouts, including small, flexible, and irregularly shaped boards

- Advanced placement heads with high precision and accuracy, ensuring reliable component placement

- User-friendly interfaces and easy programming for efficient operation and reduced downtime

Reliability in Component Placement

Reliability in component placement is a critical factor in guaranteeing the quality and consistency of electronic assemblies. Even minor variations in placement accuracy can greatly impact the overall performance and reliability of the final product. Top SMT component placement machine makers understand the importance of precision and accuracy in component placement, offering machines that provide exceptional reliability.

With placement repeatability of up to 0.001mm and positioning accuracy of ±0.025mm, these machines guarantee that components are placed with precision and consistency. Advanced vision systems enable precise alignment and component recognition, further enhancing the dependability of the placement process.

The ability to handle a wide range of component sizes and types also contributes to the dependability of the assembly process. With fast and precise component placement rates of up to 60,000 components per hour, top SMT machine manufacturers provide reliable solutions for diverse PCB assembly needs.

Advanced Technology in SMT

Advanced technology has become a hallmark of top SMT component placement machine makers, enabling them to deliver high-speed and high-precision component placement solutions that meet the demanding requirements of modern PCB assembly. These leading manufacturers have continued to push the boundaries of innovation, incorporating cutting-edge features into their machines to enhance performance and efficiency.

Some of the advanced technologies employed by top SMT machine makers include:

- Vision systems for precise component inspection and placement

- Intelligent feeders for efficient component supply

- Robotic arms for flexible and precise assembly

- AI-powered systems for optimized production and reduced errors

Efficient PCB Assembly Process

By leveraging high-speed and high-precision machines, top SMT component placement machine makers guarantee efficient PCB assembly, characterized by accurate component placement and reduced errors. This results in high-quality printed circuit boards, ideal for electronic applications.

The Surface Mount Technology (SMT) PCB assembly process is streamlined, ensuring rapid production of complex electronic components. Top machine makers prioritize speed, precision, and versatility in their products, enabling efficient reflow soldering and minimizing defects. As a result, the overall production quality of PCBs is greatly improved.

What are the Advantages of Using Top SMT Component Placement Machines Over THT?

When it comes to smt vs tht comparison, using top SMT component placement machines offers several advantages. SMT machines are capable of placing components with higher accuracy and precision, leading to better overall product quality. Additionally, SMT machines allow for smaller and more complex designs, resulting in more efficient use of PCB space.

Improved Production Output

High-volume production of printed circuit boards is facilitated by top SMT component placement machine makers, whose machines can accurately place a large quantity of components at rapid speeds, thereby greatly improving production output.

Top SMT component placement machine makers offer high-performance machines that enhance production efficiency. Some key benefits of these machines include:

- High-speed placement: Up to 100,000 components can be placed per hour, greatly improving production output.

- Precise component placement: Advanced machine vision systems guarantee accurate placement, reducing errors and improving overall production efficiency.

- Versatile machines: Machines can handle a wide range of component types and sizes, catering to diverse production needs.

- Enhanced placement accuracy: Machines detect component orientation and position for best soldering, ensuring high-quality PCB assembly.

Frequently Asked Questions

What Is SMT Component Placement?

SMT (Surface Mount Technology) component placement is a precise process of positioning electronic components onto a Printed Circuit Board (PCB).

It involves accurately placing components, such as capacitors, resistors, and integrated circuits, onto the board's surface.

This process demands high accuracy and precision to guarantee the proper functionality and reliability of the assembled electronic device.

How to Select Pick and Place Machine?

To select the best pick and place machine, a detailed evaluation of key performance indicators is essential. Visualize the production process and assess the machine's ability to meet specific requirements.

Consider the speed, accuracy, and flexibility of the machine, as well as advanced features such as vision systems and intelligent feeders.

Additionally, evaluate the user interface, maintenance requirements, and after-sales support to guarantee seamless integration into your production line.

What Is the Pick and Place Process in Smt?

In Surface Mount Technology (SMT), the pick and place process involves accurately retrieving components from feeders and positioning them onto the Printed Circuit Board (PCB). This vital step in PCB assembly guarantees precise and efficient component placement.

Leveraging vision systems, SMT pick and place machines achieve high placement speeds and precision alignment, catering to diverse production needs through manual, semi-automatic, and fully automatic machine types.

What Are the Different Types of SMT Assemblies?

SMT assemblies encompass various types, each catering to specific application requirements.

Rigid Printed Circuit Board (PCB) assemblies are the most common, featuring a solid, inflexible substrate.

Flexible PCB assemblies, on the other hand, utilize a flexible substrate, enabling dynamic applications.

Rigid-Flex assemblies combine both, offering a hybrid solution.

Additionally, there are Chip-On-Board (COB), Flip Chip, and 3D Stacked assemblies, each with unique characteristics and advantages.