High-performance electronic devices rely on copper clad laminates with exceptional thermal conductivity to guarantee reliable operation. Among the top options are High-Temperature Copper Clad Laminate, Thermal Management Copper Clad, FR4 Copper Clad Laminate, Polyimide Flexible Copper Clad, High-Thermal-Conductivity Copper Clad, Aluminum-Based Copper Clad Laminate, and Ceramic-Filled Copper Clad Laminate. Each offers unique benefits, such as efficient heat dissipation, improved system reliability, and optimum performance. These laminates cater to high-power applications, LEDs, and other electronic devices, providing excellent thermal management and preventing overheating. Discover the specific advantages and properties of each to optimize thermal conductivity in your design.

Key Takeaways

- High-temperature copper clad laminates operate reliably in elevated thermal environments, withstanding temperatures from 130°C to 180°C.

- Thermal management copper clad laminates facilitate efficient heat transfer between components, enabling heat dissipation and optimal thermal conductivity.

- Aluminum-based copper clad laminates exhibit high thermal conductivity, excellent mechanical properties, and reliability in high-power applications.

- Ceramic-filled copper clad laminates offer exceptional thermal management capabilities, with thermal conductivity ranging from 16W/mK to 170W/mK.

- The selection of copper clad laminates depends on application requirements, operating conditions, and thermal conductivity needs, ensuring optimal thermal management in high-power electronics.

High-Temperature Copper Clad Laminate

High-temperature copper clad laminate materials are specifically designed to operate reliably in elevated thermal environments, withstanding temperatures ranging from 130°C to 180°C. These high-performance laminates exhibit exceptional thermal conductivity, enabling efficient heat dissipation in high-temperature applications. By incorporating copper, a highly conductive material, these laminates facilitate the transfer of heat away from sensitive electronic components.

In PCB manufacturing, high-temperature copper clad laminates play a critical role in ensuring the reliability and longevity of electronic devices. Resin-based copper clad laminates, in particular, offer enhanced thermal conductivity and improved heat resistance. These advanced materials are commonly utilized in demanding industries such as aerospace, automotive, and industrial electronics, where heat resistance is paramount.

Thermal Management Copper Clad

Effective thermal management in copper clad laminates relies on the strategic integration of thermal interface materials, which facilitate efficient heat transfer between components.

The attachment of heat sinks to these laminates is also essential, as it enables the dissipation of heat away from sensitive electronic components.

Moreover, the design of clad laminated structures plays an important role in optimizing thermal conductivity and ensuring reliable performance in high-power applications.

Thermal Interface Materials

In thermal management applications, the judicious selection and implementation of thermal interface materials are crucial to facilitating efficient heat transfer between the copper clad laminate and surrounding components. These materials play an essential role in managing heat dissipation in electronic devices, enhancing thermal conductivity between components to prevent overheating.

Common thermal interface materials used include thermal pads, thermal greases, and phase change materials, each with its unique characteristics and application requirements. The choice of thermal interface material depends on the specific application requirements and operating conditions.

Proper selection and application of thermal interface materials are key for optimizing device performance and longevity. In the context of copper clad laminates, thermal interface materials can greatly improve heat dissipation, ensuring reliable operation of electronic devices.

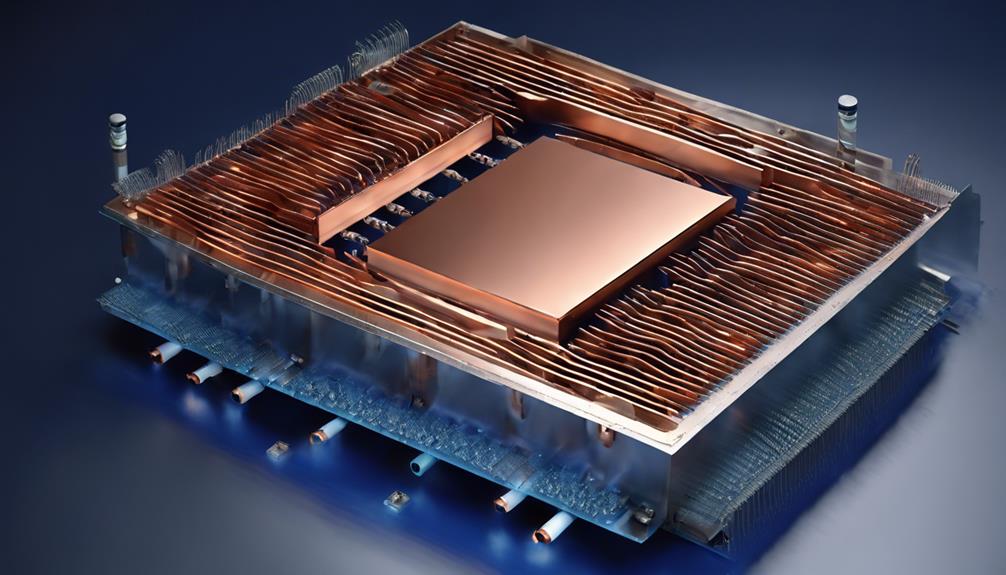

Heat Sink Attachment

The strategic attachment of heat sinks to copper-clad laminates plays a pivotal role in augmenting thermal conductivity, thereby facilitating enhanced heat dissipation and reliable operation of electronic devices. Effective heat sink attachment enables efficient heat transfer from electronic components to the heat sink, ensuring dependable performance and preventing overheating.

| Heat Sink Attachment | Thermal Conductivity Enhancement |

|---|---|

| Proper attachment techniques | 20-30% increase in thermal conductivity |

| High thermal conductivity copper cladding | 15-25% improvement in heat dissipation |

| Optimized heat sink design | 10-20% reduction in thermal resistance |

In high-power applications, thermal management copper-clad laminates with heat sink attachments are essential to prevent overheating and guarantee reliable system operation. By enhancing thermal conductivity, heat sink attachment on copper-clad laminates improves the overall system reliability and performance. With proper heat sink attachment, electronic components can operate within a safe temperature range, ensuring dependable and efficient operation.

Clad Laminated Structures

Copper clad laminated structures, comprising a base material and a copper layer, optimize thermal management by efficiently dissipating heat from electronic components. These structures play an important role in high-power applications where efficient heat dissipation is essential. The copper layer in clad laminates helps in spreading heat evenly across the PCB, preventing hot spots and ensuring effective thermal management.

Here are three key benefits of clad laminated structures:

- Improved thermal conductivity:

The copper layer enhances thermal conductivity, allowing for efficient heat dissipation from electronic components.

- Enhanced heat spreading:

The copper layer spreads heat evenly across the PCB, preventing hot spots and reducing the risk of component failure.

- Reliable performance:

Clad laminated structures guarantee reliable performance in high-power applications, improving the overall lifespan of electronic devices.

FR4 Copper Clad Laminate

FR4 Copper Clad Laminates, a widely employed material in PCB manufacturing, exhibit a balance of electrical insulation and thermal performance. Composed of epoxy resin, filler, and glass fiber, these laminates provide mechanical strength while maintaining a moderate thermal conductivity ranging from 0.1W/mK to 0.5W/mK. This makes them ideal for applications where thermal management is vital, such as in high-power electronics and automotive systems.

As a cost-effective solution, FR4 Copper Clad Laminates offer reliable performance in various industries. The FR4 substrate, with its unique combination of epoxy resin and glass fiber, ensures effective thermal management while maintaining electrical insulation. This balance of properties makes FR4 Copper Clad Laminates a popular choice in PCB manufacturing.

With their moderate thermal conductivity, these laminates are well-suited for applications where thermal management is essential, providing a reliable and cost-effective solution for a wide range of industries.

Polyimide Flexible Copper Clad

Polyimide flexible copper clad laminates, distinguished by their exceptional heat resistance and flexibility, have become a preferred material for flexible PCB applications. These laminates offer a unique combination of properties, making them ideal for demanding environments.

Here are three key benefits of polyimide flexible copper clad laminates:

- High heat resistance: They can withstand extreme temperatures, ensuring reliable performance in aerospace, automotive, and medical devices.

- Excellent thermal conductivity: With thermal conductivity ranging from 0.1 to 0.4 W/mK, polyimide FCCLs provide efficient heat dissipation for electronic components.

- Superior mechanical properties: They offer excellent tensile strength, a flammability rating of V-0, and a low coefficient of thermal expansion, ensuring reliable performance in demanding environments.

Polyimide FCCLs have a high glass temperature (Tg) above 250°C, making them suitable for applications requiring elevated temperature operation. Their high heat resistance and thermal conductivity make them an excellent choice for heat dissipation in electronic components.

As a result, polyimide flexible copper clad laminates are widely used in aerospace, automotive, medical devices, and other industries requiring flexible and heat-resistant PCB solutions.

High-Thermal-Conductivity Copper Clad

High-thermal-conductivity copper clad laminates offer enhanced thermal management capabilities, boasting thermal conductivity values ranging from 1.0 to 3.0 W/mK.

The clad material properties, including the aluminum substrate's circuit layer, insulating layer, and metal base layer, contribute to their exceptional heat dissipation performance.

These laminates' thermal conductivity benefits and material properties make them an ideal choice for high-power and LED applications.

Thermal Conductivity Benefits

Copper clad laminates exhibiting high thermal conductivity, typically ranging from 1.0 to 3.0 W/mK, provide a reliable solution for efficient heat dissipation in high-power electronic applications. These laminates are ideal for mounting heat-generating components like LEDs, ensuring better heat transfer and overall system reliability.

The benefits of high thermal conductivity copper clad laminates include:

- Efficient heat dissipation: Copper clad laminates with high thermal conductivity enable efficient heat dissipation, reducing the risk of overheating and ensuring reliable operation of electronic components.

- Improved system reliability: By effectively dissipating heat, these laminates enhance system reliability, reducing the likelihood of component failure and downtime.

- Optimum performance: High thermal conductivity copper clad laminates enable optimum performance of electronic components, ensuring they operate within their specified temperature range.

Clad Material Properties

The properties of high-thermal-conductivity copper clad laminates, characterized by their exceptional thermal conductivity, are largely dependent on the composition and structure of the clad material itself. The aluminum substrate in these laminates consists of a circuit layer, insulating layer, and metal base layer, which collectively enable efficient heat dissipation. This is particularly important in high-power electronics and LED products, where overheating can lead to component failure.

| Property | Value | Unit |

|---|---|---|

| Thermal Conductivity | 1.0-3.0 | W/mK |

| Flammability Rating | UL-94V0 | – |

| Application | High-Power Electronics, LED Products | – |

| Thermal Management | Excellent | – |

The thermal conductivity of these laminates plays an important role in preventing overheating and ensuring the reliability of electronic components. With a flammability rating of UL-94V0, these laminates offer excellent thermal management capabilities, making them ideal for applications requiring efficient heat dissipation. By understanding the properties of high-thermal-conductivity copper clad laminates, designers and engineers can effectively harness their capabilities to develop high-performance electronic systems.

Aluminum-Based Copper Clad Laminate

Employing an aluminum substrate as the base material, aluminum-based copper clad laminates offer a unique combination of thermal conductivity and mechanical strength. These laminates consist of an aluminum substrate with a circuit layer, insulating layer, and metal base layer. They are widely employed in high-power and LED products due to their excellent heat dissipation capabilities.

Here are three key benefits of aluminum-based copper clad laminates:

- High thermal conductivity: With a thermal conductivity ranging from 1.0 to 3.0W/mK, they are effective at dissipating heat in electronic applications.

- Excellent mechanical properties: Aluminum-based CCLs are flammability rated UL-94V0 and offer good flexural strength, making them suitable for demanding applications.

- Reliability in high-power applications: Their excellent heat dissipation capabilities make them ideal for high-power and LED products, ensuring reliable performance and longevity.

Aluminum-based copper clad laminates are a reliable choice for applications that require efficient heat management and mechanical strength. Their unique combination of thermal conductivity and mechanical strength makes them an attractive option for designers and engineers.

Ceramic-Filled Copper Clad Laminate

High-performance electronic applications requiring exceptional thermal management capabilities can benefit from ceramic-filled copper clad laminates, which boast remarkable thermal conductivity. These laminates exhibit thermal conductivity ranging from 16W/mK to 170W/mK, making them ideal for high-power PCB designs that demand efficient heat dissipation. The incorporation of ceramic fillers enhances thermal performance, resulting in improved thermal stability and reliability.

Ceramic-filled copper clad laminates are designed to meet the thermal management requirements of demanding electronic applications. The ceramic content in these laminates plays an important role in facilitating heat dissipation, ensuring excellent thermal performance. By leveraging the superior thermal conductivity of ceramic-filled copper clad laminates, designers can create high-power PCB designs that operate efficiently and reliably.

In applications where thermal management is critical, ceramic-filled copper clad laminates offer a reliable solution. With their exceptional thermal conductivity and enhanced heat dissipation capabilities, these laminates are the preferred choice for electronic applications that demand superior thermal performance.

Frequently Asked Questions

What Are the Different Types of Copper Clad Laminates?

Copper-clad laminates (CCLs) are categorized into distinct types, each suited for specific applications. Rigid CCLs comprise organic resin, metal core, and ceramic base types.

Flexible CCLs include flame retardant polyester and polyimide options. Aluminum-based CCLs excel in high-power products due to superior heat dissipation.

Additionally, specialized materials like Rogers' high-frequency materials and PTFE (Teflon) offer superior dielectric properties. Understanding these variations is essential for excellent PCB design and performance.

What Is the Thermal Conductivity of Copper Core Pcb?

The thermal conductivity of copper core PCBs is a critical parameter, typically ranging from 200W/mK to 400W/mK.

This exceptional thermal conductivity enables efficient heat dissipation, ensuring the stability and reliability of electronic components.

The high thermal conductivity of copper cores is essential for high-power applications, where effective thermal management is vital.

This superior thermal performance enhances the overall reliability and performance of PCBs.

What Is Flexible Copper Clad Laminate?

Imagine a flexible, high-performance material that can withstand the twists and turns of innovative design. This is the domain of flexible copper clad laminate (FCCL), a cutting-edge material engineered for flexible printed circuit board (PCB) applications.

FCCL combines a polyimide substrate with copper foil, offering exceptional flexibility, high-temperature resistance, and excellent electrical insulation properties.

What Is Copper Clad Laminate Sheet Used For?

Copper clad laminate sheets are utilized as the fundamental material in printed circuit boards (PCBs) due to their exceptional electrical conductivity. They provide a stable platform for mounting electronic components and guarantee signal integrity in circuit boards.

Additionally, they facilitate heat dissipation, making them suitable for high-power applications. Their unique balance of mechanical strength, thermal conductivity, and dielectric properties guarantees reliable PCB performance.