To guarantee a safe and successful soldering experience, electronic hobbyists must prioritize essential safety precautions to prevent accidents, injuries, and damage to equipment and components. A well-ventilated workspace, proper protective gear, and controlled soldering iron handling are vital. Additionally, electrical safety, equipment storage, and waste disposal must be addressed. By following established protocols and maintaining focus, hobbyists can minimize risks and achieve reliable connections. By taking these initial steps, you'll be well on your way to a safe and successful soldering experience, with many more best practices waiting to be discovered.

Key Takeaways

- Ensure a well-ventilated workspace to prevent harmful fume inhalation and maintain a clutter-free area to minimize accidents.

- Wear protective gear, including safety glasses, gloves, and a lab coat, to prevent burns and fume exposure.

- Handle soldering irons safely by controlling temperature, using insulated handles, and avoiding direct contact with hot tips.

- Implement electrical safety measures, such as unplugging irons when not in use, using grounded outlets, and keeping water away from the soldering area.

- Store equipment and materials safely, including designating a secure area, using heat-resistant holders, and storing solder rolls and flux in airtight containers.

Choose a Safe Work Area

When setting up a workspace for soldering, it is essential to select a well-ventilated area that is free from flammable materials and clutter, providing a stable and distraction-free environment that allows for precise and accurate work.

A well-ventilated work area is important in preventing the inhalation of harmful soldering fumes, which can be detrimental to one's health. Additionally, keeping flammable materials at a safe distance reduces the risk of fire hazards, ensuring a safe working environment.

A clutter-free workspace is also important, as it helps to prevent accidents and distractions, allowing the soldering process to be carried out with utmost precision and accuracy. Moreover, a sturdy and stable work surface is necessary to prevent accidental spills or tip-overs of soldering equipment.

Lastly, proper lighting in the work area enhances visibility, enabling electronic hobbyists to work with precision and accuracy. By choosing a safe work area, electronic hobbyists can minimize risks and guarantee a safe and successful soldering experience.

Wear Protective Gear Always

Beyond the importance of a safe work area, wearing protective gear is an essential aspect of soldering safety. It shields electronic hobbyists from the inherent hazards associated with the soldering process. Wearing safety gear is not a choice but a necessity to guarantee personal safety and prevent accidents or injuries.

Protective gear like safety glasses, gloves, and a lab coat serve as a barrier against solder splashes and burns. They minimize the risk of exposure to harmful fumes that can trigger respiratory issues and allergies. Additionally, wearing long sleeves and closed-toe shoes provides an extra layer of protection during soldering activities.

It is crucial to wear safety gear consistently, as it significantly reduces the risk of accidents or injuries. By wearing protective equipment, electronic hobbyists can maintain a safe and secure soldering environment, allowing them to focus on their projects with confidence.

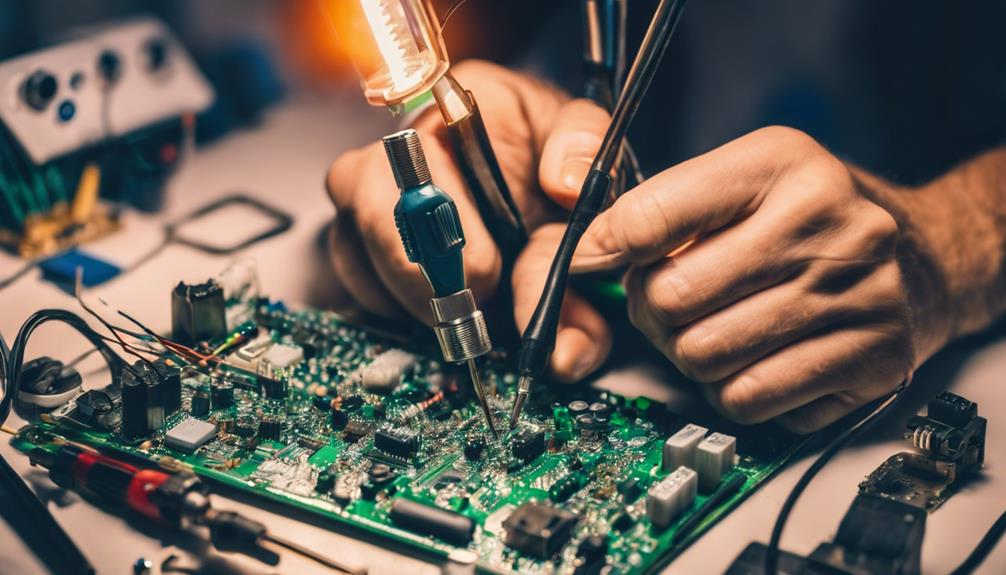

Handle Soldering Iron With Care

When handling soldering irons, it is vital to exercise extreme caution to prevent accidents and guarantee efficient soldering. Proper iron temperature control and safe handling techniques are essential to avoid burns, electrical shock, and damage to components.

Iron Temperature Control

Setting the ideal temperature on the soldering iron is an important step in achieving reliable bonds and preventing damage to sensitive components in electronic hobby projects. Iron temperature control is necessary for efficient and safe soldering practices in electronics. The ideal temperature depends on the type of solder being used, and adjusting the iron temperature accordingly ensures proper melting and bonding.

A temperature that is too high can damage components, while a temperature that is too low can result in weak bonds.

Maintaining proper iron temperature control is essential for effective soldering and preventing damage to components. The soldering iron tip should be set to the best temperature for the specific solder material being used. This ensures quality solder joints and prevents overheating, which can lead to component failure.

Safe Handling Techniques

Proper handling techniques are important to guarantee safe and efficient soldering, as improper handling can lead to accidents, injuries, and damage to components. When handling a soldering iron, it's vital to exercise caution and adhere to best practices to avoid potential hazards.

To make sure safe handling, follow these guidelines:

- Hold the soldering iron by the insulated handle to prevent burns or electrical shocks.

- Use a heat-resistant stand to securely place the hot soldering iron when not in use.

- Avoid touching the soldering iron tip directly, as it can reach high temperatures and cause burns.

Additionally, it's crucial to maintain a clean and organized workspace to prevent flux residue from accumulating on your soldering iron tip.

Regularly cleaning the soldering tip will ensure efficient performance and prevent damage to components.

Prevent Electrical Shock Hazards

Electrical shock hazards pose a significant threat to electronic hobbyists, and following essential safety precautions is important to preventing potentially fatal accidents.

When working with soldering irons, the risk of electrical shocks is ever-present. To mitigate this risk, it is essential to unplug the soldering iron when not in use, ensuring that accidental electrical shocks are avoided. Additionally, it is important to use a grounded outlet and inspect cords for damage to prevent potential shock hazards.

Moreover, wearing insulated gloves and footwear can provide an extra layer of protection against electric shocks while soldering. It is also crucial to keep water and other liquids away from the soldering area, reducing the risk of electrical hazards.

Finally, never touch the soldering iron tip with bare hands, as this can cause burns and increase the risk of electrical shocks.

Safely Store Soldering Equipment

One vital aspect of soldering safety often overlooked is the storage of equipment, which, if not done correctly, can lead to accidents, damage, or even fires. Proper storage of soldering equipment is crucial to prevent unauthorized access, damage, and fires.

To ensure safe storage, follow these essential guidelines:

- Designate a secure area: Store soldering equipment in a designated, secure area to prevent unauthorized access or mishandling.

- Use heat-resistant holders: Keep soldering irons and tips in a heat-resistant holder or stand to avoid accidental burns or damage.

- Store materials properly: Store solder rolls and flux in airtight containers to prevent contamination and extend their shelf life.

Ventilate the Workspace Properly

Proper ventilation is crucial to maintaining a safe soldering environment.

To guarantee ideal airflow, it is essential to remove contaminants quickly and utilize exhaust fans effectively, thereby minimizing the risk of inhalation of toxic fumes.

Remove Contaminants Quickly

Effective ventilation of the workspace is critical to swiftly eliminate harmful contaminants generated during soldering operations, thereby safeguarding the health and safety of electronic hobbyists. Proper ventilation is essential to prevent the accumulation of hazardous substances in the air, reducing the risk of respiratory issues and promoting a safer and healthier environment for soldering activities.

To remove contaminants quickly, consider the following key measures:

- Maintain a well-ventilated area: Guarantee good airflow by opening windows, using fans, or installing ventilation systems to remove harmful fumes and vapors.

- Implement ventilation measures: Install exhaust systems, ventilation hoods, or local exhaust ventilation (LEV) systems to capture and remove contaminants at the source.

- Monitor and maintain airflow: Regularly inspect and maintain ventilation systems to ascertain they are functioning correctly and providing adequate airflow.

Use Exhaust Fans Effectively

By incorporating exhaust fans or fume extractors into the ventilation strategy, electronic hobbyists can greatly enhance the removal of hazardous soldering fumes and maintain a safer working environment.

Proper ventilation is vital to prevent the accumulation of potentially hazardous fumes and vapors in the soldering area. The use of exhaust fans or fume extractors helps reduce the risk of inhaling toxic substances released during soldering activities.

To create a safe and healthy environment for soldering, especially when working with lead-based solder or flux, adequate ventilation is essential. Consider using a ventilation hood or local exhaust system to effectively remove soldering fumes and protect your respiratory health.

By implementing an effective ventilation system, electronic hobbyists can minimize the risks associated with soldering fumes and establish a safer working environment.

Manage Soldering Temperature Wisely

When working with sensitive electronic components, it is essential to manage soldering temperature wisely, as excessive heat can cause irreparable damage. Proper temperature management is vital to prevent cold joints and guarantee a successful soldering process.

To achieve ideal solder joints, follow these temperature management guidelines:

- Adjustable temperature settings: Use a soldering iron with adjustable temperature settings to prevent overheating delicate electronic components.

- Refer to manufacturer's guidelines: Refer to the manufacturer's guidelines for the appropriate temperature range for the solder you are using.

- Avoid excessive heat: Avoid excessively high temperatures that can lead to damage or burning of the circuit board.

Avoid Overheating the Soldering Iron

One essential aspect of soldering safety is avoiding overheating the soldering iron, as excessive heat can lead to damaged components, poor solder joints, and even safety hazards.

When the soldering iron is overheated, it can cause solder to splatter, creating a hazardous environment. Additionally, high temperatures can degrade the soldering tip, reducing its lifespan.

To prevent these issues, it is important to maintain the correct temperature, ensuring smooth soldering and preventing overheating.

Following temperature guidelines for different solder types is crucial in preventing overheating issues. Each solder type has its recommended temperature range, and deviating from this range can lead to undesirable consequences.

By adhering to these guidelines, electronic hobbyists can guarantee that their soldering iron operates within a safe and optimal temperature range. This attention to detail is significant in achieving reliable and efficient solder joints.

Keep Children Away From Soldering

To guarantee a safe and hazard-free environment, it is essential to keep children away from soldering activities, as their curiosity and inexperience can lead to serious accidents and injuries. Children should never be near soldering activities due to the risk of burns, inhalation of harmful fumes, and exposure to hot soldering equipment. The soldering iron and other tools used in soldering can cause serious injuries to children if mishandled or touched.

To maintain a safe environment, follow these guidelines:

- Store soldering equipment out of reach: Keep soldering irons, wires, and other tools in a secure location where children cannot access them.

- Designate a child-free soldering area: Create a designated soldering area that is off-limits to children to minimize the risk of accidents or injuries.

- Educate children about soldering risks: Teach children about the dangers of soldering and establish clear boundaries to guarantee their safety around electronic hobby projects.

Stay Alert and Avoid Distractions

Maintaining a safe soldering environment requires not only keeping children away from the soldering area, but also staying alert and focused on the task at hand to prevent accidents or mistakes. As an electronic hobbyist, it is important to stay focused on the soldering task to guarantee precision and avoid errors.

One of the essential safety tips is to avoid distractions such as phone calls or conversations while soldering, as they can divert your attention and lead to accidents. A cluttered workspace can also be a significant distraction, so it is essential to keep your workspace organized and free of clutter. This will minimize the risk of accidents and enable you to stay focused on the task.

Practicing mindfulness and attentiveness while soldering is also critical to prevent errors or injuries. By staying alert and avoiding distractions, you can ensure a safe and successful soldering experience. Remember, safety tips such as staying focused and avoiding distractions are important for maintaining a safe soldering environment.

Follow Proper Soldering Techniques

By following established soldering protocols, electronic hobbyists can guarantee reliable connections and prevent common pitfalls that can compromise the integrity of their projects. Proper soldering techniques are essential to secure the quality and reliability of electronic assemblies.

Here are three essential soldering tips to keep in mind:

- Preheat and maintain the correct temperature: Secure the soldering iron is set to the correct temperature for the solder being used to achieve best results.

- Clean the soldering iron tip regularly: Remove any oxidation or debris that can affect soldering quality by cleaning the tip regularly.

- Apply solder correctly: Apply solder to the heated components, not the soldering iron, to achieve strong and reliable connections.

Dispose of Waste Materials Safely

When participating in soldering activities, it is essential to prioritize the safe disposal of waste materials. This involves adopting proper disposal methods and handling hazardous waste responsibly.

Proper Disposal Methods

The responsible disposal of waste materials is a critical component of a safe and sustainable electronic hobbyist practice, as it guarantees environmental protection and maintains a clean and healthy workspace. To secure proper disposal, electronic hobbyists must dispose of used solder, flux, and cleaning materials in designated hazardous waste containers to prevent environmental contamination.

Here are three essential steps to follow:

- Store waste materials in sealed containers to avoid exposure to harmful substances and secure safe disposal practices.

- Follow local regulations and guidelines for disposing of electronic waste, including solder scraps and flux residue.

- Consider recycling options for solder waste to minimize environmental impact and promote sustainability in electronic hobbyist practices.

Hazardous Waste Handling

Proper disposal of hazardous waste is only half the battle, as electronic hobbyists must also handle waste materials safely to prevent environmental contamination and health risks.

Hazardous waste generated from soldering activities, including solder scraps, flux residue, and contaminated materials, requires careful handling and disposal. To mitigate risks, store waste in sealed containers to prevent leakage and exposure. It is important to dispose of waste according to local regulations, ensuring proper handling and recycling.

Direct contact with solder waste should be avoided to prevent skin irritation and inhalation of harmful substances. Implementing safe waste disposal practices is essential to protect oneself, others, and the environment from potential hazards.

Adherence to disposal regulations is crucial to prevent environmental pollution and health risks. By adopting responsible hazardous waste handling practices, electronic hobbyists can minimize their ecological footprint and ensure a safe working environment.

Frequently Asked Questions

What Are the Safety Precautions When Soldering Electronics?

When soldering electronics, safety precautions are crucial to prevent injuries and damage. Wearing protective gear, including safety glasses, gloves, and long sleeves, is vital to shield against solder splashes and burns.

Additionally, working in a well-ventilated area or utilizing a fume extractor helps mitigate exposure to harmful fumes and vapors. A first aid kit should be nearby, and a soldering iron stand guarantees safe storage when not in use.

How to Protect Yourself When Soldering?

When soldering, it's essential to don the armor of protection to shield yourself from the fiery sparks of risk. Just as a knight prepares for battle, a soldering warrior must gear up with safety glasses and gloves to deflect solder splashes and burns.

Additionally, a well-ventilated arena or fume extractor will safeguard against noxious fumes. By suiting up with these essential protections, you'll conquer the soldering battlefield with confidence and precision.

What Is the Number 1 Rule of Soldering?

When engaging in soldering activities, the essential rule is to avoid touching the tip of the soldering iron at all costs. This vital precaution safeguards against severe burns and injuries.

Direct contact with the iron's hot tip can result in serious harm, emphasizing the importance of maintaining a safe distance and utilizing heat-resistant tools to handle the iron.

What Are the Best Soldering Iron Tips for Electronics?

As a master artisan shapes a fine sculpture, a skilled electronics enthusiast must carefully select the ideal soldering iron tip to craft precise connections.

For intricate work on circuit boards, conical tips with fine sizes (0.5mm) are ideal.

Chisel tips excel at efficient heat transfer for larger joints, while bevel tips reach tight spots, creating strong solder joints.

High-quality copper tips guarantee durability and peak heat conductivity, empowering electronics enthusiasts to shape their masterpieces.