Optimizing SMT component placement for small circuits necessitates meticulous planning to guarantee efficient routing, thermal management, and signal integrity. Strategic component placement is essential to prevent signal degradation and thermal issues. Collaboration with manufacturers during the design phase is important. Advanced SMT machines with precise alignment and multiple placement heads aid in efficient component placement. Optimizing PCB design for assembly involves precise Gerber files, stencils, and fiducial marks. By following guidelines for component orientation, alignment, and feeder utilization, manufacturers can secure high-quality assemblies. To discover further insights into maximizing pick and place efficiency, explore the intricacies of small circuit assembly.

Key Takeaways

- Precise component placement is crucial in small circuits to prevent signal integrity issues and ensure efficient routing.

- Collaborating with manufacturers during the design phase helps optimize SMT component placement for small circuits.

- Grouping components by function and separating power management components minimizes interference and ensures effective signal path control.

- Maintaining continuous ground planes and equal trace widths ensures signal integrity and balanced heat distribution in small circuits.

- Optimizing feeder configurations and utilizing gang pick heads minimizes nozzle switches, enhancing assembly speed and efficiency in small circuits.

Key Considerations for Small PCBs

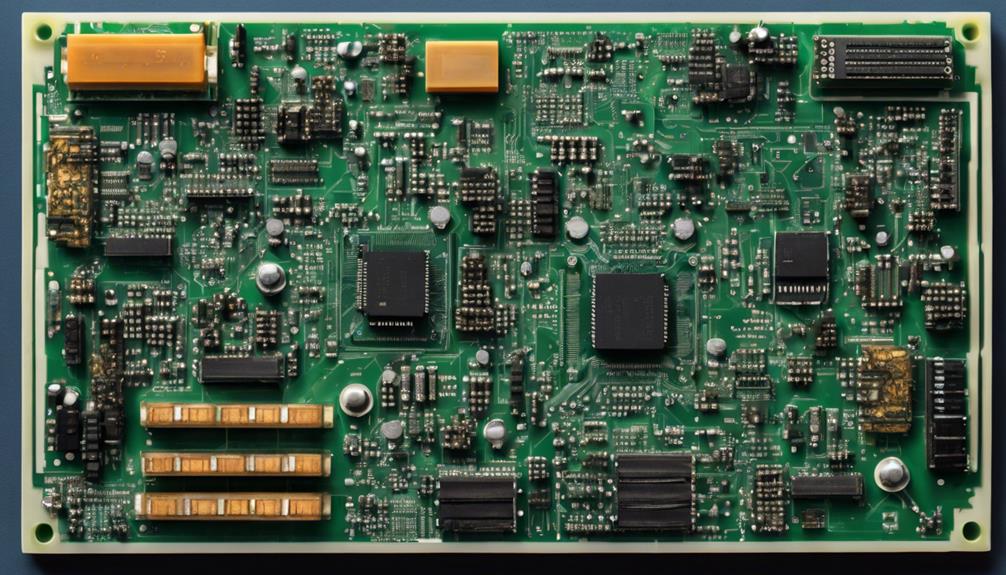

In small printed circuit boards (PCBs), where available space is severely limited, meticulous planning and strategic component placement are essential to guarantee peak performance, reliability, and manufacturability.

The compact nature of small PCBs demands precise placement of components to ensure efficient routing and best use of available space. High component density in these circuits necessitates strategic placement to prevent signal integrity issues and thermal management concerns.

Thermal management is critical in small PCBs, as closely spaced components can lead to overheating if not properly managed. Effective component placement can mitigate thermal issues by ensuring adequate airflow and heat dissipation.

Moreover, signal integrity considerations become more important in small circuits to avoid interference and electromagnetic interference. To ensure an efficient component layout for assembly, it is essential to collaborate with manufacturers during the design phase.

SMT Component Placement Machines

Sixty thousand components per hour is the pivotal placement speed achievable with state-of-the-art SMT component placement machines, which utilize advanced vision systems to guarantee precise alignment on the PCB. These machines are designed to optimize the placement process, ensuring accurate and efficient component placement.

| Feature | Description |

|---|---|

| Placement Speed | Up to 60,000 components per hour |

| Vision Systems | Advanced systems for precise component alignment |

| Placement Heads | Multiple heads for increased efficiency |

| Feeders | Accurate supply of components to placement heads |

High-end SMT component placement machines feature multiple placement heads, which significantly increase the placement speed and efficiency. Different types of feeders are used to supply components to the placement heads accurately, ensuring the correct components are placed in the correct locations. Machine configuration and optimization play a critical role in the success of SMT component placement, allowing manufacturers to achieve high-quality and reliable assemblies.

Optimizing PCB Design for Assembly

Setting up the PCB design to facilitate efficient assembly is vital, as it directly impacts the quality and reliability of the final product. To optimize PCB design for assembly, it is essential to contemplate the assembly process from the outset. This involves generating accurate Gerber files, which provide essential data for configuring machines for precise component placement.

Stencils created for solder paste application also play a pivotal role in SMT assembly optimization. Moreover, incorporating fiducial marks in the PCB design aids in accurate component placement, enhancing the efficiency of the assembly process. The arrangement of SMT components on the PCB also greatly influences the smoothness of assembly, ultimately impacting overall production quality.

Electronic Component Placement Tips

When designing a printed circuit board, strategically placing electronic components is essential to guarantee peak performance, reliability, and thermal management. Effective component placement is critical for the best PCB layout.

Some essential tips for placing electronic components include:

- Grouping components by function to control signal paths effectively, reducing electromagnetic interference and signal degradation.

- Separating power management components to minimize interference and noise, ensuring dependable power supply to the circuit.

- Placing heat-generating components at the center of the board for efficient heat dissipation, preventing thermal hotspots and component failure.

- Maintaining continuous ground planes to ensure signal integrity, reducing electromagnetic radiation and noise.

SMT Component Placement Guidelines

Efficient SMT component placement relies on adhering to meticulous guidelines. Even slight deviations can compromise the overall performance and reliability of the assembled circuit. To guarantee excellent SMT component placement, manufacturers provide specific guidelines considering thermal factors and signal integrity.

These guidelines dictate precise component orientation and alignment, which is achieved through the utilization of automated placement equipment. Additionally, following equal trace width for pins helps balance heat distribution during reflow, preventing issues like tombstoning.

In addition, SMT part spacing can be tighter for reflow compared to wave soldering, optimizing the soldering process for surface mount components. By following these guidelines, manufacturers can secure accurate functionality and reliability in their assembled circuits.

Best Practices for PCB Placement

Optimizing PCB placement requires a strategic approach. Components should be deliberately grouped by function to facilitate efficient return paths and minimize signal interference. This deliberate placement enables the creation of continuous ground planes, which are essential for best signal integrity.

To achieve best PCB placement, consider the following best practices:

Separate power management components from other circuit elements to reduce electromagnetic interference.

Guarantee ground planes are continuous without interruptions to maintain signal integrity.

Consider component size and its impact on heat dissipation and airflow path planning on the PCB.

Strategically position ground planes on intermediate layers to reduce signal interference.

What are the best practices for optimizing SMT component placement in small circuits?

When it comes to optimizing SMT component placement in small circuits, a comprehensive approach is essential. By carefully considering factors such as component orientation, signal integrity, and thermal management, engineers can ensure that the placement is both efficient and effective. Taking a comprehensive approach to SMT component placement can lead to improved circuit performance and reliability.

Maximizing Pick and Place Efficiency

To maximize pick and place efficiency, it is essential to implement efficient machine placement strategies that minimize travel time and reduce component misplacement.

Effective management of component batch sizes is also critical, as it directly impacts production throughput and feeder utilization.

Machine Placement Strategies

In high-volume production environments, manufacturers rely on advanced machine placement strategies to maximize pick and place efficiency, ensuring the rapid assembly of small circuits. Efficient pick-and-place machines are vital for meeting market demands and guaranteeing error-free assembly.

To achieve the best results, manufacturers employ various machine placement strategies that prioritize precision component placement.

Some key features of these strategies include:

- High-end pick and place machines capable of achieving up to 200,000 Components Per Hour (CPH) for efficient placement.

- Machines with multiple nozzles that allow simultaneous placement of various components, enhancing productivity.

- Conveyor belts in machine configuration that aid in smooth transfer of PCBs for continuous assembly.

- Precision heads and gantries in machine setups that ensure accurate component placement on small circuits.

Component Batch Sizes

Six key factors influence the ideal component batch size for maximizing pick and place efficiency in SMT assembly processes. By optimizing component batch sizes, manufacturers can greatly improve the efficiency of their SMT assembly processes.

Smaller batch sizes, for instance, reduce changeover times and minimize downtime in pick and place machines, resulting in increased productivity. Batch sizes can be adjusted based on component complexity, size, and production requirements, allowing for a tailored approach to maximize pick and place efficiency.

Efficient batching strategies can enhance overall production throughput and reduce assembly costs, promoting smoother workflow coordination and enhancing assembly line productivity. In small circuits, optimizing component batch sizes is essential to achieving maximum pick and place efficiency.

Optimizing Feeder Utilization

Efficient feeder utilization is essential to maximizing pick and place efficiency, as it enables the smooth and uninterrupted supply of components to the assembly line. This is particularly vital in small circuit assembly, where production output and speed are paramount.

To optimize feeder utilization, several key considerations must be made:

- Proper feeder setup reduces machine downtime, increasing overall productivity during SMT assembly.

- Utilizing gang pick heads allows simultaneous pickup of multiple components, enhancing assembly speed.

- Consistent feeder performance guarantees accurate component supply for seamless pick and place operations.

- Optimizing feeder configurations minimizes nozzle switches, streamlining the assembly process for small circuits.

Frequently Asked Questions

Where Should Components Be Placed in a Circuit?

When determining component placement in a circuit, strategic positioning is vital to minimize signal interference and optimize heat dissipation.

Components should be grouped by function and voltage levels to guarantee efficient signal integrity and noise reduction.

Avoid placing components near heat sources or high-power areas to prevent thermal issues.

How Do You Manage Component Placement to Optimize Signal Integrity?

Surprisingly, signal integrity is often compromised by inadequate component placement. To optimize signal integrity, a systematic approach is essential.

Components should be strategically positioned to separate high-speed signals from noise sources, while impedance control and precise routing techniques are employed for signal paths.

Additionally, grouping components by function and voltage levels minimizes interference, and strategically placed ground planes reduce electromagnetic interference, ensuring signal fidelity.

How Can I Improve My SMT Process?

To improve your SMT process, focus on optimizing component placement, ensuring precise alignment, and minimizing defects.

Implement fiducial marks and tooling strips to enhance machine accuracy and grip.

Leverage PCB design software, such as Cadence Allegro, to streamline component orientation and placement rules.

This methodical approach will enhance signal integrity, reduce assembly time, and increase overall process efficiency.

How Do I Know Where to Place Components on a Pcb?

As the puzzle pieces of a PCB design come together, the question arises: where to place the components? Coincidentally, the answer lies at the intersection of functionality and precision.

To determine best placement, consider the fiducial marks on the PCB, thermal management, and signal integrity. Manufacturer guidelines and automated placement equipment guarantee accurate positioning.

Proper orientation and alignment are essential for successful SMT assembly.