Managing heat in LED lighting systems is essential to prevent premature degradation and reduced efficiency. Effective thermal management strategies include the implementation of heat dissipation techniques, thermal interface materials, and active cooling systems. Optimizing PCB design, heat sink design, and LED chip structure can also enhance thermal performance. Ambient temperature control, current level management, and the use of thermal simulation software are additional methods to mitigate overheating. By adopting these strategies, LED lighting systems can maintain peak performance, extend lifespan, and guarantee reliable operation. Further exploration of these methods reveals a thorough approach to thermal management in LED lighting systems.

Key Takeaways

- Effective thermal management in LED lighting systems involves implementing heat dissipation strategies, such as heat sinks and thermal interface materials.

- PCB heat dissipation methods, including thermal vias and optimized design, help reduce thermal resistance and improve LED performance.

- Material selection is critical, balancing thermal conductivity, thickness, and compliance to ensure efficient heat transfer and minimize interface resistance.

- Active cooling solutions, like fans, and passive cooling techniques, such as natural convection, can be used to enhance airflow and ventilation, preventing thermal buildup.

- Advanced thermal analysis, including CFD simulations, helps optimize thermal design and predict temperature distribution, ensuring efficient heat dissipation and improved LED lifespan.

Thermal Management Strategies

Effective thermal management in LED lighting systems relies on the implementation of a combination of heat dissipation strategies, including the strategic use of heat sinks, thermal pads, and efficient cooling solutions. A well-designed thermal management system is essential to maintaining ideal performance and longevity in LED lighting systems.

Heat sinks, in particular, play a key role in dissipating heat generated by LEDs, ensuring efficient heat transfer and preventing overheating. Thermal interface materials are also essential in facilitating efficient heat transfer between the LED and heat sink.

In high-power LED applications, active cooling systems, such as fans or liquid cooling, may be necessary to manage heat effectively. By optimizing heat dissipation performance, LED lighting systems can achieve improved energy efficiency, contributing to sustainability efforts.

The LED lighting industry recognizes the importance of thermal management, and therefore, thermal simulations and CFD analysis are increasingly used to design and optimize heat dissipation strategies. By adopting a holistic thermal management approach, LED lighting systems can operate at their full potential, delivering high-quality illumination while minimizing energy consumption.

PCB Heat Dissipation Methods

In addition to the strategic use of heat sinks and thermal interface materials, the printed circuit board (PCB) itself plays an essential role in dissipating heat generated by LEDs, and its design can greatly impact the overall thermal performance of the system.

To achieve efficient heat dissipation, PCB design must be optimized. This can be achieved by selecting PCB core materials with high thermal conductivity, such as metal core and MCPCBs. The strategic placement of LED modules on the PCB also profoundly influences thermal performance. Moreover, incorporating thermal vias within the PCB helps conduct heat away from LED components, enhancing overall heat dissipation capabilities.

| PCB Design Consideration | Impact on Heat Dissipation |

|---|---|

| PCB core materials | Superior thermal conductivity for efficient heat dissipation |

| Thermal vias | Conduct heat away from LED components, enhancing heat dissipation |

| Contact surfaces and thermal interface materials | Essential for effective heat dissipation, maximizing heat dissipation efficiency |

Utilizing advanced heat simulation software aids in designing PCBs that maximize heat dissipation efficiency in LED lighting systems. By optimizing PCB design, efficient heat dissipation can be achieved, ensuring reliable and long-lasting LED lighting systems.

Effective Heat Sink Design

Aluminum alloy heat sinks, prized for their high thermal conductivity, are strategically designed to dissipate heat generated by LED lighting systems, thereby maintaining ideal operating temperatures.

Effective heat sink design plays a vital role in efficient heat dissipation, ensuring ideal operating temperatures for LEDs and reducing the risk of performance degradation. Proper heat sink materials with high thermal conductivity, such as aluminum alloy, are preferred for efficient heat dissipation.

The design of heat sinks includes features like fins and surface treatments to enhance thermal performance. Incorporating thermal simulation software aids in optimizing heat sink design for maximum heat dissipation efficiency.

By selecting the right heat sink materials and designing them strategically, LED lighting systems can maintain ideal operating temperatures, ensuring reliable and efficient performance. Well-designed heat sinks can greatly enhance thermal performance, making them a critical component in LED lighting systems.

Optimizing LED Chip Design

The thermal performance of LED chips can be greatly enhanced through deliberate design considerations, as the compact nature of these chips inherently leads to higher power densities and increased heat generation. Optimizing LED chip design is important for effective heat dissipation, and this can be achieved through ideal layout and thermal management solutions.

Compact chips, in particular, require careful design to mitigate hotspot formation and guarantee efficient heat dissipation. Thicker substrates can be employed to spread heat more effectively, reducing the risk of hotspot formation. Furthermore, the selection of chip materials and structures plays a significant role in balancing performance and heat generation in LED lighting systems.

Advanced chip packaging techniques, such as flip-chip bonding, can further enhance thermal conductivity, leading to improved heat dissipation. By carefully considering these factors, LED chip design can be optimized to minimize heat generation and ensure reliable operation. This, in turn, enables the development of high-power, high-reliability LED lighting systems.

Ambient Temperature Control

By regulating ambient temperatures within the ideal range of 25-35°C, LED lighting systems can maintain peak performance and extend their lifespan. Excessive temperatures can precipitate premature degradation and reduced efficiency. Ambient temperature control is important in industrial and commercial settings where LEDs are subject to varying environmental conditions.

To guarantee peak performance, it is essential to:

- Implement proper ventilation to remove heat generated by the LED lighting system.

- Install cooling systems to regulate ambient temperatures within the recommended operating range.

- Monitor ambient temperatures to prevent overheating and minimize heat-related issues.

Current Level Management

In LED lighting systems, current level management is crucial for controlling heat generation. Excessive current can significantly reduce the lifespan and efficiency of LEDs by producing more heat at higher current levels. Implementing current regulation techniques is essential to control heat dissipation in LED fixtures. Maintaining ideal current levels minimizes heat generation, ensuring the efficiency and longevity of the lighting system.

Overdriving LEDs with excessive current can lead to increased heat output and decreased efficiency, underscoring the significance of proper current level management. Effective current regulation allows LED fixtures to operate safely and efficiently, preventing excessive heat generation and ensuring peak performance.

Prioritizing current level management enables designers and manufacturers to create LED lighting systems that offer high performance, energy efficiency, and long-lasting solutions.

Thermal Interface Materials

When designing LED lighting systems, thermal interface materials play a critical role in managing heat dissipation.

To achieve peak performance, it is essential to take into account the thermal conductivity of these materials, select the appropriate type for the application, and minimize interface resistance to guarantee efficient heat transfer.

Thermal Conductivity Matters

Optimizing thermal conductivity between LED components and heat sinks relies heavily on the strategic selection and application of thermal interface materials. These materials play an essential role in enhancing heat transfer, reducing thermal resistance, and improving the overall efficiency of heat dissipation in LED lighting systems.

The choice of thermal interface materials has a significant impact on the performance and longevity of LED lighting systems. By bridging the gap between LED components and heat sinks, thermal interface materials help maintain LED efficiency and reduce junction temperatures. This, in turn, improves the overall reliability and lifespan of the system.

Some key benefits of thermal interface materials include:

- Improved heat transfer: High thermal conductivity materials enhance heat transfer between LED components and heat sinks.

- Reduced thermal resistance: Thermal interface materials minimize thermal resistance, allowing for more efficient heat dissipation.

- Increased efficiency: By reducing thermal resistance and improving heat transfer, thermal interface materials help maintain LED efficiency and performance.

Material Selection Criteria

Among the critical factors influencing the effectiveness of thermal interface materials in LED lighting systems is the selection of materials that balance thermal conductivity, thickness, and compliance to guarantee efficient heat transfer. The thermal conductivity of a TIM determines its ability to dissipate heat, while its thickness affects the material's thermal resistance. Compliance, on the other hand, guarantees that the TIM conforms to the surface roughness of the components, minimizing air gaps and thermal resistance.

| TIM Type | Thermal Conductivity (W/mK) |

|---|---|

| Thermal Grease | 0.5-5 |

| Thermal Pads | 0.5-10 |

| Phase Change Materials | 0.1-5 |

| Thermal Tapes | 0.1-2 |

Proper selection of TIMs based on application requirements helps enhance LED performance and longevity. High-performance TIMs with low thermal resistance play a key role in optimizing heat dissipation in LED lighting systems. By understanding the material selection criteria for TIMs, designers can create efficient heat transfer pathways, ensuring reliable and high-performance LED lighting systems.

Interface Resistance Reduction

By minimizing interface resistance, thermal interface materials play an important role in enhancing heat transfer efficiency in LED lighting systems. These materials effectively reduce the resistance between components, allowing heat to dissipate more efficiently.

By filling gaps and irregularities between surfaces, thermal interface materials optimize heat dissipation and improve the overall thermal management of LED lighting systems.

To achieve the best heat transfer efficiency, it is essential to select the right thermal interface material for the specific application. Some common types of thermal interface materials include:

- Thermal greases: These are paste-like substances that fill gaps and irregularities, reducing interface resistance and enhancing heat transfer efficiency.

- Thermal pads and tapes: These materials provide a conformable interface, filling gaps and ensuring optimal heat transfer between components.

- Phase change materials: These materials change phase from solid to liquid as they absorb heat, providing a high level of heat transfer efficiency.

Proper selection and application of thermal interface materials can greatly enhance the thermal performance of LED lighting systems, ensuring reliable and efficient operation.

Airflow and Ventilation

Effective heat dissipation in LED lighting systems relies heavily on the strategic incorporation of airflow and ventilation mechanisms to prevent thermal buildup and guarantee peak performance.

Adequate airflow around LED components is essential to dissipate heat effectively and maintain peak performance. Proper ventilation helps prevent heat buildup in LED lighting systems, ensuring longevity and consistent light output.

Efficient airflow design can greatly impact the temperature of LED fixtures, improving energy efficiency and reducing the risk of overheating. Strategic placement of ventilation openings and fans can enhance heat dissipation in LED systems, promoting durability and reliability.

Effective airflow management is vital for maintaining safe operating temperatures in LED lighting setups, preventing potential damage from overheating.

Passive Cooling Techniques

Passive cooling techniques are crucial in LED lighting systems to effectively dissipate heat without the need for active cooling methods.

This is achieved through the strategic implementation of natural convection methods, carefully designed heat sink geometries, and the selection of best thermal interface materials.

Natural Convection Methods

Natural convection methods, which leverage the surrounding air to dissipate heat from LED lighting systems, offer a reliable and efficient means of thermal management. By harnessing the natural temperature differentials between the LED fixture and the surrounding air, heat is dissipated through convection currents.

This passive cooling technique is energy-efficient and cost-effective, making it an attractive solution for managing heat in LED lighting systems.

To enhance natural convection, heat sinks with fins are often employed to increase the surface area for heat transfer. Additionally, proper airflow design around LED fixtures is essential to facilitate effective heat dissipation.

By optimizing these design parameters, natural convection methods can provide reliable thermal management for LED lighting systems.

Key Considerations for Effective Natural Convection:

- Heat sinks with fins: Increase surface area for heat transfer to enhance natural convection.

- Airflow design: Ensure adequate airflow around LED fixtures to facilitate heat dissipation.

- Temperature differentials: Leverage natural temperature differences between the LED fixture and surrounding air to drive convection currents.

Heat Sink Designs

In conjunction with natural convection methods, heat sink designs play a vital role in LED lighting systems. They efficiently dissipate heat generated by LEDs and printed circuit boards (PCBs) to maintain ideal operating temperatures.

Heat sink designs in LED lighting systems involve using materials like aluminum alloy with high thermal conductivity. This enables efficient passive heat dissipation. Effective heat sink design includes optimizing surface area, fin shapes, and thermal conductivity for efficient cooling.

Additionally, radiative heat dissipation and surface treatments on heat sinks improve overall thermal performance in LED systems. Proper heat sink selection and placement are essential for maintaining ideal temperatures and extending LED lifespan.

By optimizing heat sink designs, LED lighting systems can operate within ideal temperatures, ensuring reliable and efficient performance. This, in turn, contributes to a longer LED lifespan and reduced maintenance costs.

Thermal Interface Materials

Effective thermal management in LED lighting systems relies heavily on the strategic integration of thermal interface materials, which greatly enhance heat transfer efficiency between LED components and heat sinks. The proper selection of thermal interface materials is vital in reducing thermal resistance and enhancing heat dissipation. This, in turn, helps maintain ideal LED performance and longevity.

The following thermal interface materials are commonly used:

- Thermal pads: Provide a reliable and consistent thermal interface between LED components and heat sinks.

- Thermal greases: Fill microscopic gaps between surfaces, reducing thermal resistance and enhancing heat transfer efficiency.

- Phase change materials: Absorb and release heat as they change phase, providing a dynamic thermal interface solution.

The thickness and application method of these materials play a significant role in their effectiveness in dissipating heat. By carefully selecting and applying thermal interface materials, designers can minimize thermal resistance and guarantee efficient heat transfer. This careful consideration is essential for maintaining ideal LED performance and extending the lifespan of LED lighting systems.

Active Cooling Solutions

How do LED lighting systems overcome the challenge of heat dissipation, particularly in high-power applications?

One effective solution is the integration of active cooling solutions, which play an important role in maintaining ideal operating temperatures. Active cooling solutions, such as fans, are commonly integrated into LED fixtures to enhance airflow and prevent heat buildup. By dissipating heat effectively, fans aid in reducing junction temperatures, thereby extending the lifespan of the LEDs.

In high-power LED applications, active cooling systems are essential for maintaining ideal operating temperatures, which is critical for ensuring reliable performance and longevity. The use of fans in LED lighting systems contributes to improved performance, reliability, and longevity.

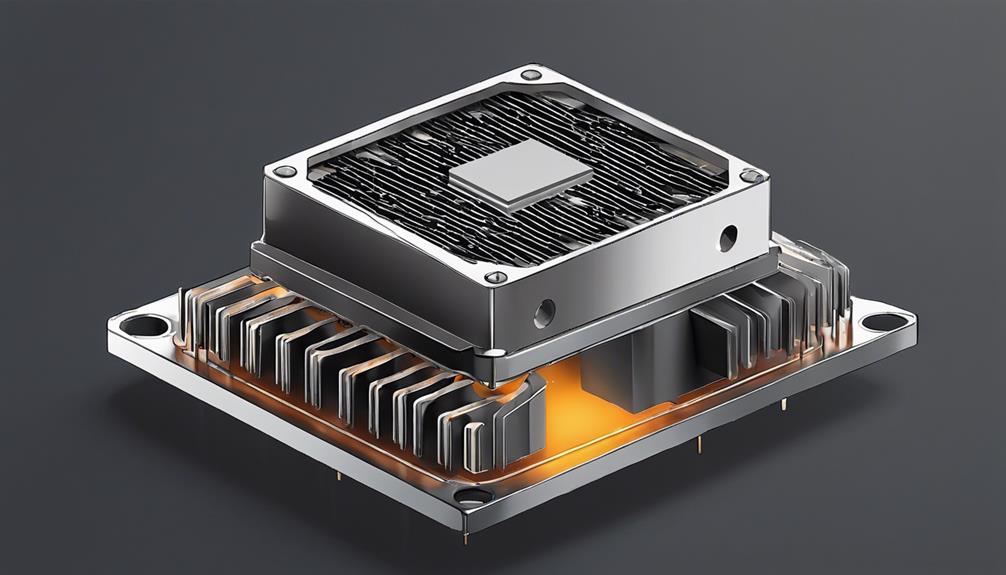

Heat Sink Material Selection

Frequently, the thermal performance of an LED lighting system hinges on the judicious selection of heat sink materials, which plays a critical role in maintaining ideal operating temperatures. The choice of heat sink material has a major impact on the system's ability to dissipate heat efficiently.

When selecting a heat sink material, thermal conductivity is a vital factor. Aluminum alloys are a popular choice due to their high thermal conductivity, making them suitable for LED lighting systems. However, copper heat sinks offer even better thermal conductivity, although they are heavier and more expensive.

Here are three key considerations for heat sink material selection:

- Thermal conductivity: Higher thermal conductivity enables more efficient heat dissipation.

- Surface area: Increasing the surface area through the use of fins or heat pipes enhances heat dissipation.

- Thermal interface materials: Using thermal pads and compounds ensures ideal heat transfer between the LED and heat sink.

Proper heat sink material selection is essential for efficient heat management and prolonged lifespan of LED lights. By understanding the importance of thermal conductivity, surface area, and thermal interface materials, designers can create LED lighting systems that operate within ideal temperature ranges, ensuring reliable performance and extended lifespan.

LED Module Thermal Design

In LED module thermal design, the choice of thermal interface materials and heat sink design are critical components.

Thermal interface materials facilitate efficient heat transfer between the LED chip and heat sink, while optimized heat sink design enables effective dissipation of heat away from the module.

Thermal Interface Materials

The thermal interface material's thermal conductivity, thickness, and application method are critical factors in determining its effectiveness in facilitating efficient heat transfer between LED modules and heat sinks. The choice of thermal interface materials greatly impacts the thermal resistance and overall heat dissipation in LED lighting systems.

Proper thermal interface materials guarantee efficient heat transfer, reducing the risk of overheating by providing a pathway for heat to move away from the LED modules. This, in turn, enhances the longevity and performance of LED lighting systems by managing heat effectively.

Key considerations for selecting thermal interface materials:

- Thermal conductivity: High thermal conductivity ensures effective heat transfer between LED modules and heat sinks.

- Thickness: Ideal thickness minimizes thermal resistance and maximizes heat dissipation.

- Application method: Correct application ensures uniform contact and maximizes heat transfer.

Heat Sink Design

Optimizing heat sink design is important in LED module thermal design, as it directly impacts the efficient dissipation of heat away from the LED modules.

A well-designed heat sink should maximize surface area to enhance heat dissipation efficiency. This is essential in maintaining LED junction temperatures within ideal operating ranges, ensuring longevity and preventing performance degradation.

Heat sinks with high thermal conductivity materials, such as aluminum alloy, greatly improve thermal management in LED lighting systems. By minimizing thermal resistance, heat can transfer away from LEDs effectively, reducing junction temperatures and enhancing overall LED performance.

Effective heat sink design plays an important role in preventing LED performance degradation due to excessive heat buildup. By optimizing heat sink design, LED manufacturers can guarantee reliable and efficient operation of their products.

Advanced Thermal Analysis

Sophisticated thermal management in LED lighting systems relies heavily on advanced thermal analysis techniques, which offer an in-depth understanding of heat transfer mechanisms and airflow patterns. These techniques enable the optimization of heat dissipation in LED lighting technology, ensuring efficient thermal performance and prolonged lifespan.

Advanced thermal analysis involves the use of Computational Fluid Dynamics (CFD) simulations, which accurately predict temperature distribution, airflow patterns, and thermal performance in complex LED designs. By simulating heat transfer and airflow, engineers can evaluate different cooling solutions and optimize heat management strategies for LED fixtures.

Some key benefits of advanced thermal analysis include:

- Enhanced heat dissipation: Advanced thermal analysis helps design efficient thermal paths, ensuring efficient heat dissipation and maintaining ideal operating temperatures.

- Improved thermal performance: Thermal analysis tools enable engineers to evaluate and optimize thermal performance, leading to improved LED performance and lifespan.

- Streamlined design efficiency: Advanced thermal analysis streamlines the design process, reducing the need for physical prototypes and accelerating the development of high-performance LED lighting systems.

Frequently Asked Questions

How Do I Ensure Thermal Management in High-Power LED Applications?

When designing high-power LED applications, thermal management is vital to prevent overheating, which can lead to decreased luminous efficacy and reduced lifespan.

To guarantee effective thermal management, it is imperative to take into account the LED's thermal resistance, junction temperature, and heat sink design.

Implementing a thorough thermal management strategy involves selecting suitable materials, optimizing heat sink geometry, and incorporating active cooling solutions, such as fans or heat pipes, to maintain ideal operating temperatures.

Can I Use Thermal Tapes for Mounting Heat Sinks in LED Systems?

When considering thermal interface materials for mounting heat sinks in LED systems, thermal tapes can be a viable option. These tapes offer a convenient, low-cost solution for filling gaps and ensuring peak thermal conductivity. However, their thermal impedance and durability should be carefully evaluated to guarantee reliable performance.

It is essential to select a thermal tape that meets the specific requirements of your LED application, considering factors such as operating temperature, pressure, and environmental conditions.

What Is the Ideal Thermal Interface Material for High-Reliability Leds?

When selecting a thermal interface material (TIM) for high-reliability LEDs, an important consideration is the material's thermal conductivity, stability, and compatibility.

Ideal TIMs exhibit high thermal conductivity (>5 W/m-K), low thermal impedance, and minimal thermal resistance.

Graphite-based materials, such as graphite foils or graphite-based thermal tapes, are often preferred due to their high thermal conductivity and stability.

However, ceramic-based TIMs, like boron nitride or alumina, can also be suitable alternatives.

Ultimately, the best TIM choice depends on the specific LED application and operating conditions.

Are There Any Safety Considerations for LED Cooling Systems?

When designing LED cooling systems, safety considerations are paramount. Guarantee that the thermal management system is designed to prevent electrical shock, fire hazards, and burns.

Implement protective measures such as insulation, grounding, and over-temperature protection. Additionally, consider the risk of thermal runaway and make sure that the system is designed to mitigate this risk.

Comply with relevant safety standards and regulations, such as UL and IEC, to ensure a safe and reliable LED cooling system.

Can I Use Simulation Software to Predict LED Thermal Performance?

Can simulation software accurately predict LED thermal performance? Empirical evidence suggests yes. By leveraging advanced algorithms and thermal modeling, simulation tools can accurately forecast heat dissipation patterns, junction temperatures, and thermal resistances.

This enables designers to optimize LED layouts, material selections, and cooling strategies, ensuring reliable and efficient thermal management. By validating simulations against experimental data, designers can confidently rely on virtual prototyping to streamline the development process and mitigate thermal-related failures.