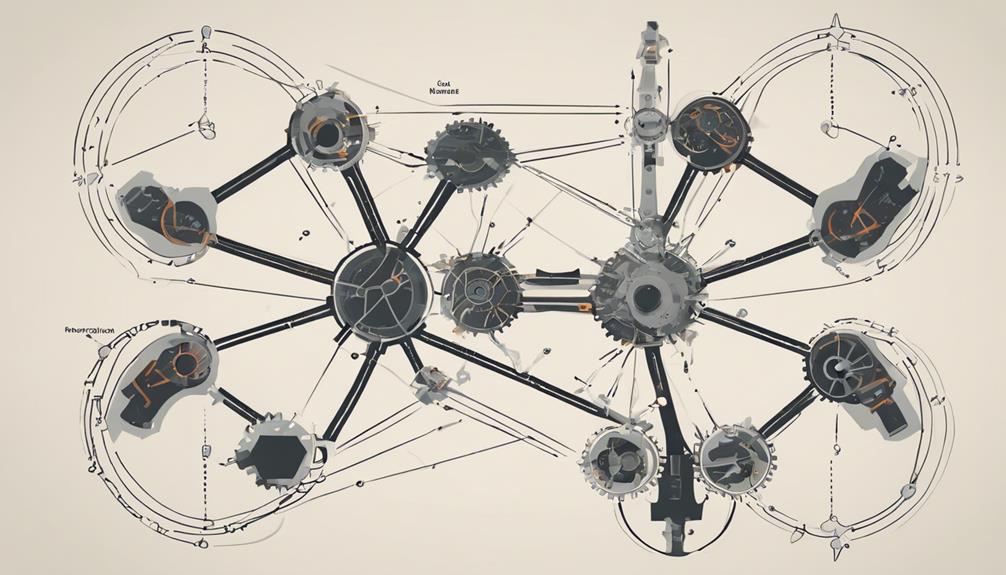

The fabrication process flow chart is a structured framework that guides the production of semiconductor devices through three distinct stages. The material preparation stage involves selecting and processing high-quality semiconductor wafers, cleaning, doping, and oxidizing the wafer, and defining patterns through lithography. The component assembly stage integrates individual components onto the semiconductor substrate, establishes electrical connections, and designs the assembly process using software. The finishing and quality control stage involves treating the device, conducting rigorous testing, and rectifying defects. As we further examine the fabrication process, the intricacies of each stage will come into sharp focus.

Key Takeaways

- The fabrication process involves three stages: material preparation, component assembly, and finishing and quality control.

- Material preparation sets the foundation for manufacturing, involving cleaning, doping, oxidizing, and lithography to define patterns.

- Component assembly integrates individual components onto the semiconductor substrate, requiring precise placement and alignment.

- Metallization patterns establish electrical connections, and software aids in designing and simulating the assembly process.

- Finishing and quality control involve treatments like polishing and coating, followed by rigorous testing to ensure compliance with specifications.

Material Preparation Stage

Selecting and processing high-quality base materials, such as semiconductor wafers, is essential in the material preparation stage, as it sets the foundation for creating integrated circuits with precise structures and properties. This stage is the first step in the fabrication process flow chart, and it is critical in guaranteeing the quality and reliability of the final product.

The key processes involved in material preparation include cleaning, doping, and oxidizing the semiconductor wafer. Additionally, lithography is applied to define patterns for subsequent fabrication steps. Proper material preparation is imperative, as it lays the groundwork for the entire manufacturing process.

A well-executed material preparation stage ensures that the integrated circuits produced meet the required specifications and possess the desired properties. By following a precise flow chart, manufacturers can ensure that their material preparation stage is optimized, resulting in high-quality integrated circuits that meet the required standards.

Component Assembly Stage

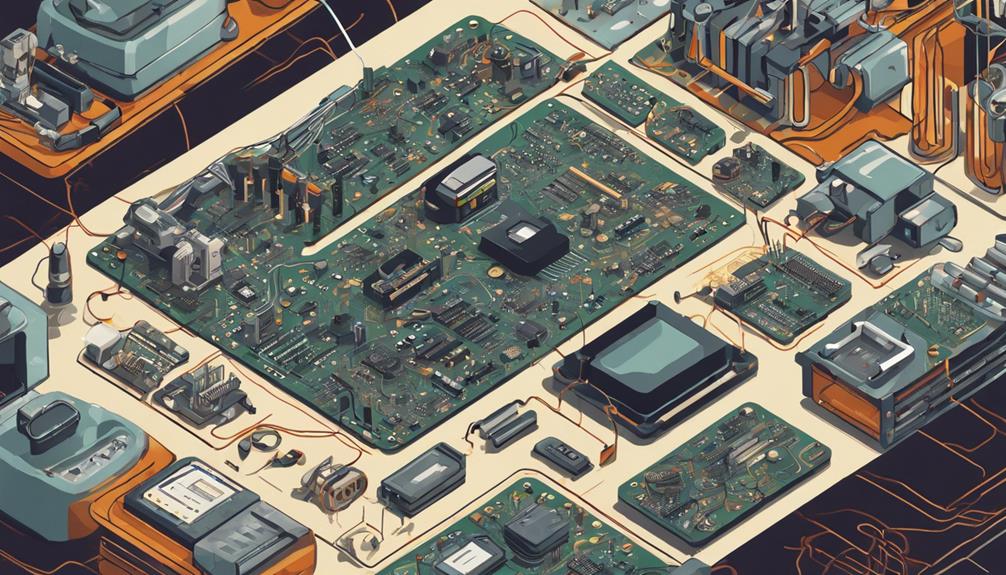

In the component assembly stage, individual components, including resistors, capacitors, and transistors, are meticulously integrated onto the semiconductor substrate to form a functional integrated circuit. This stage is vital in the manufacturing flowchart, as it involves precise placement and alignment of components to guarantee proper functionality of the integrated circuit.

The assembly process follows specific design rules to make certain the components are positioned correctly for efficient operation. The components are connected using metallization patterns or wires to establish the necessary electrical connections. The flow diagram for this stage would include symbols used to represent each component and their connections. This accurate representation is essential for analyzing new designs and optimizing the product flow.

The tasks listed in this stage are critical, as any misalignment or incorrect connection can compromise the entire integrated circuit. Software offers valuable tools for designing and simulating the assembly process, allowing for precise analysis and refinement of the steps involved. By following the precise steps outlined in this stage, manufacturers can guarantee the production of high-quality, reliable integrated circuits.

Finishing and Quality Control

Following the component assembly stage, the finishing and quality control stage ensues, where the integrated circuit undergoes final treatments and rigorous testing to guarantee compliance with specifications and customer requirements.

In this stage, the finishing process involves treatments such as polishing, coating, or surface modifications to enhance appearance and functionality. The quality control process validates that the product meets the required standards through a wide variety of inspection methods, including visual checks, measurements, and performance tests.

These methods validate product integrity and identify any defects that may require rectification. Defect rectification may occur during the finishing stage if quality control identifies deviations from standards. The quality assurance protocols in place aim to meet customer requirements and maintain consistent product quality, ensuring that the final product meets the desired specifications.

Frequently Asked Questions

What Is the Three 3 Major Steps of Fabrication Flow?

The three major steps of fabrication flow are lithography, deposition, and etching.

Lithography involves pattern transfer onto a substrate using photoresist materials.

Deposition adds or removes materials to create specific structures, while etching selectively removes materials to form desired circuit patterns.

These sequential steps are critical in the fabrication of integrated circuits and semiconductor devices, enabling the creation of complex electronic components.

What Are the 3 Types of Process Flow Diagram?

As the threads of complexity are woven into the fabric of process management, three distinct types of process flow diagrams emerge to guide us through the labyrinth of operational efficiency.

The high-level process flow diagram provides a bird's-eye view of the entire process, while the detailed process flow diagram explores the intricacies of specific steps and sequences.

Meanwhile, the process flow diagram for decision-making shines a spotlight on critical decision points, illuminating the path to optimized operations.

What Are the Three Levels of Flowchart?

The three levels of flowcharts serve distinct purposes in process visualization.

High-level flowcharts provide a broad overview, focusing on major steps and decision points.

Detailed flowcharts outline specific actions and interactions.

Deployment flowcharts specify task assignments and roles.

This hierarchical approach guarantees a thorough understanding of a process, from overall structure to detailed execution.

What Are the Steps in Process Flow Chart?

Did you know that 85% of companies that implement process flow charts experience a significant reduction in production errors?

A process flow chart consists of three primary stages: input, processing, and output.

The input stage involves gathering raw materials or information, followed by the processing stage where actual work or transformation occurs.