Defects in printed circuit board (PCB) production can arise from a complex interplay of factors, including design flaws, material and component issues, manufacturing process problems, human error, and environmental factors, all of which can have a significant impact on the quality and reliability of the final product. These defects can manifest as soldering errors, mechanical damage, contamination, and dimensional inaccuracies, among others. Understanding the root causes of these defects is essential for identifying areas for improvement and implementing effective quality control measures. Further analysis of these factors can reveal additional insights into the complexities of PCB production.

Key Takeaways

- Defects in printed circuit boards (PCBs) can occur due to design flaws, including insufficient spacing between traces and acute trace angles.

- Soldering errors, mechanical damage, and contamination are common causes of PCB defects during production.

- Material and component issues, such as material defects and catastrophic failures, can also lead to PCB defects.

- Human error and negligence, including misreading schematics and incorrect component installation, can result in PCB defects.

- Manufacturing process problems, including inadequate training and equipment maintenance, can increase the likelihood of PCB defects.

Causes of PCB Defects

In the complex landscape of printed circuit board (PCB) production, defects can arise from a multitude of sources, including soldering errors, mechanical damage, contamination, dimensional inaccuracies, and plating flaws, which can have far-reaching consequences on the overall quality and reliability of the final product.

These defects can be attributed to various causes, including manufacturing issues, design flaws, and material defects. Soldering defects, in particular, are a common occurrence, resulting from improper soldering techniques, inadequate temperature control, or contaminated surfaces.

Additionally, contamination risks during the assembly process can also lead to PCB defects. Improper design, inadequate material selection, and manufacturing variability further exacerbate the issue.

Understanding the causes of PCB defects is important for implementing preventive measures and process controls to mitigate their occurrence. By identifying and addressing these causes, manufacturers can reduce the likelihood of defects and ensure the production of high-quality PCBs.

Design Flaws and Errors

Design flaws and errors in printed circuit board production can have far-reaching consequences, as they can lead to a multitude of defects that compromise the overall quality and reliability of the final product.

Inadequate PCB design can result in insufficient spacing between traces and acute trace angles, severely impacting manufacturability. Additionally, errors in PCB design can lead to defects such as plating voids, acid traps, and missing solder mask between pads, ultimately affecting the overall functionality of the board.

Inadequate consideration for thermal management can result in burned components due to high temperatures during manufacturing. Moreover, PCB design errors can contribute to age-related deterioration, causing wear and breakdown of components over time.

It is essential to understand and address design flaws to prevent defects and uphold the quality and reliability of printed circuit boards. By optimizing PCB design, manufacturers can mitigate soldering issues, ensure effective thermal management, and facilitate efficient component placement, ultimately producing high-quality boards that meet performance expectations.

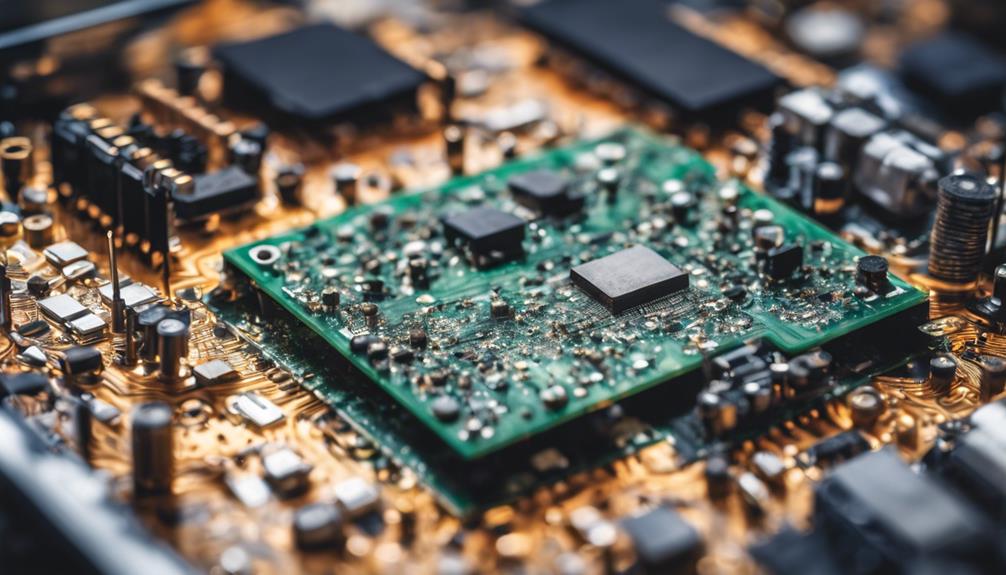

Material and Component Issues

Frequently, material defects and component issues prove to be a significant source of defects in printed circuit board production, often manifesting as catastrophic failures or latent defects that only become apparent during operation.

Material defects, such as resin starvation and pinholes, can lead to PCB failures during production. Similarly, component issues, including the use of obsolete or incorrect components, can result in assembly problems. Inadequate quality control of incoming materials can also contribute to defects in PCB production.

Additionally, poor soldering techniques and contaminated solder can lead to defects in printed circuit board production. Furthermore, lack of proper component spacing and alignment can cause issues during the PCB assembly process.

It is essential to address these material and component issues to prevent defects in PCB production. By implementing robust quality control measures and ensuring the use of high-quality materials and components, manufacturers can minimize the risk of defects and guarantee reliable PCB production.

Manufacturing Process Problems

In the field of manufacturing process problems, two critical factors contribute to defects in printed circuit board production.

Insufficient training provided to production staff can lead to mistakes and oversights, while inadequate equipment maintenance can result in faulty machinery and compromised product quality.

These factors can have a cumulative effect, exacerbating existing issues and introducing new defects into the production process.

Insufficient Training Provided

During the manufacturing process, the lack of thorough training for production staff can have far-reaching consequences, including errors and defects in assembly processes. Insufficient training in PCB production can lead to a multitude of defects, compromising the overall quality of the printed circuit board.

Some of the key areas where inadequate training can manifest include:

- Inadequate training on soldering techniques, resulting in poor quality solder joints and electrical failures

- Lack of understanding of PCB design guidelines, leading to layout mistakes and functionality issues

- Inadequate knowledge of ESD precautions, causing electrostatic discharge-related defects in PCB production

Providing extensive training to production staff is essential to mitigate these defects. This includes training on soldering techniques, PCB design guidelines, handling components, and ESD precautions.

Inadequate Equipment Maintenance

One of the most critical yet often overlooked aspects of printed circuit board production is the regular maintenance of equipment, as neglecting this crucial step can have far-reaching consequences for the quality and reliability of the final product. Inadequate equipment maintenance in PCB production can lead to increased downtime and lower production efficiency, ultimately affecting the overall quality and reliability of the final product.

| Consequence | Impact on PCB Production |

|---|---|

| Equipment Malfunctions | Decreased Quality and Reliability |

| Maintenance Delays | Disruption to Production Schedules |

| Increased Downtime | Lower Production Efficiency |

| Costly Repairs | Increased Production Costs |

| Defects in PCBs | Reduced Customer Satisfaction |

Proper equipment maintenance is essential to prevent unexpected breakdowns and costly repairs in PCB manufacturing. Regular maintenance checks can help identify potential issues early on, reducing the risk of defects in PCB production. By prioritizing equipment maintenance, manufacturers can make sure that their production schedules are met, and high-quality PCBs are delivered to customers on time.

Human Error and Negligence

As the most prevalent and preventable cause of defects in printed circuit board production, human error can have far-reaching consequences, including costly rework and compromised product reliability. Human error plays a vital role in defects in PCB production, with misreading schematics, incorrect component installation, and poor soldering being common errors.

These mistakes can lead to rework, resulting in wasted time and resources. To minimize human errors, design engineers, assemblers, and quality engineers are involved in the production cycle. Proper training and attention to detail are important in reducing human errors in PCB production.

Some common human errors in PCB production include:

- Misreading schematics, leading to incorrect component installation

- Poor soldering techniques, resulting in faulty connections

- Inadequate quality control, leading to defects escaping detection

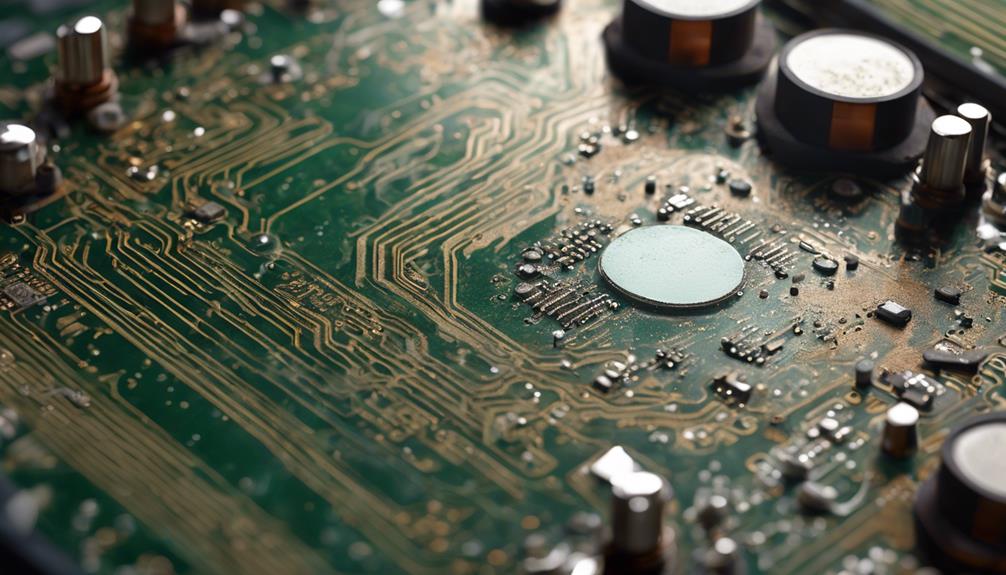

Environmental Factors and Aging

As printed circuit boards are highly susceptible to environmental influences, it is imperative to take into account the impact of humidity and moisture exposure, temperature fluctuations, and the acceleration of the aging process on PCB performance and longevity. These factors can greatly compromise the integrity of PCBs, leading to premature degradation and failure.

Humidity and Moisture Exposure

Exposure to high humidity levels can have devastating consequences for printed circuit boards, causing moisture absorption that can lead to warping, component damage, and compromised solder joints. This can ultimately result in short circuits and electrical failures, rendering the PCB unusable.

The impact of humidity on PCBs is multifaceted:

- Moisture absorption can cause warping, compromising the structural integrity of the board.

- Compromised solder joints can lead to short circuits and electrical failures over time.

- Environmental factors like humidity can accelerate the aging process, increasing the risk of defects and malfunctions.

To mitigate these risks, it is essential to produce and store PCBs in a controlled environment with regulated humidity levels. Proper handling and storage practices are vital to minimize the impact of humidity and moisture exposure on PCB production.

Temperature Fluctuations Matter

Temperature fluctuations, another critical environmental factor, can have a profound impact on the performance and reliability of printed circuit boards, particularly when combined with humidity and moisture exposure. The expansion and contraction of PCB materials due to temperature changes can cause warping and stress on soldered joints, leading to premature failure.

High temperatures during PCB production can also result in burned components, affecting the overall functionality of the board. To mitigate these effects, PCBs should have a Glass Change Temperature (Tg) of at least 170°C to withstand operating temperatures without deformation.

Environmental factors like heat and humidity can accelerate the aging process of PCB components, potentially causing premature failure. Maintaining a climate-controlled manufacturing environment can help minimize the impact of temperature fluctuations on PCB production and performance.

Aging Process Acceleration

Environmental factors, including heat, humidity, and contaminants, can greatly speed up the aging process of printed circuit boards, compromising their reliability and lifespan. High temperatures and humidity levels can lead to expansion in PCBs, causing warping and damage to soldered joints. This acceleration of the aging process can be mitigated by manufacturing PCBs in a controlled climate environment.

The following environmental factors contribute to aging process acceleration:

- High temperatures that cause expansion and warping of PCBs

- Humidity levels that lead to moisture absorption and damage to soldered joints

- Foreign debris, such as dust, hair, and fibers, that can cause overheating and accelerate aging

Maintaining safe humidity levels through climate control can help prevent premature aging of printed circuit boards. By managing environmental factors, manufacturers can safeguard the reliability and lifespan of their PCBs.

It is essential to take these factors into account during the production process to prevent defects and ensure the quality of the final product.

Assembly and Soldering Issues

During the assembly and soldering stages of printed circuit board production, defects can arise from a combination of human error, inadequate soldering techniques, and design flaws, ultimately compromising the reliability and performance of the final product.

| Defect Type | Description | Causes |

|---|---|---|

| Solder Bridging | Unintended solder connections between components | Insufficient solder, poor soldering technique |

| Insufficient Solder | Inadequate solder application | Inadequate solder application, poor soldering technique |

| Tombstoning | Component standing upright on the PCB | Poor soldering technique, incorrect PCB footprint |

| Solder Balling | Solder forming into balls instead of a smooth joint | Poor soldering technique, contamination |

| Lifted or Missing Pads | Pads lifted or missing from the PCB | Human error, incorrect PCB footprint |

Assembly defects, such as solder bridging, insufficient solder, tombstoning, solder balling, and lifted or missing pads, can be attributed to human error, inadequate soldering techniques, and design flaws. Incorrect PCB footprints can also lead to assembly problems during PCB production. Proper soldering techniques are essential to avoid defects like cold joints and solder bridges. By understanding the root causes of these defects, manufacturers can take proactive measures to prevent them, ensuring the production of high-quality printed circuit boards.

Quality Control and Inspection

To prevent the defects that arise during assembly and soldering from compromising the reliability and performance of the final product, a rigorous quality control process is implemented to detect and address any issues early on. This process involves thorough inspection of the printed circuit boards (PCBs) to identify defects and confirm that they meet design specifications and industry standards.

Automated inspection methods, such as Automated Optical Inspection (AOI) and X-Ray, are used to detect soldering and component placement issues.

Early detection of defects enables prompt rework or repair, reducing the likelihood of electrical failures and performance issues.

Effective quality control measures confirm that PCBs meet the required standards, reducing the risk of costly rework and ensuring the production of high-quality PCBs.

Frequently Asked Questions

What Causes Faults on a Printed Circuit Board?

Faults on a printed circuit board (PCB) can arise from a multitude of sources. Soldering irregularities, mechanical damage, and contamination are common causes of faults, which can lead to electrical shorts, open circuits, and complete PCB failure.

Additionally, dimensional inaccuracies, plating flaws, and design flaws can also contribute to faults. To mitigate these issues, it is essential to implement robust process controls, conduct design for manufacturability analysis, and maintain strict contamination controls.

What Are the Defects of PCB Fabrication?

According to industry reports, a staggering 70% of PCB failures can be attributed to fabrication defects.

Now, regarding the defects of PCB fabrication, common issues include soldering defects, mechanical damage, contamination, dimensional inaccuracies, and plating flaws.

These defects can lead to electrical shorts, open circuits, and complete PCB failure.

It is essential to detect and resolve defects early in the fabrication process to guarantee the production of high-quality PCBs.

What Causes Damage to PCB Board?

Damage to PCB boards can be attributed to various factors. Elevated temperatures during manufacturing can cause burnout, while age-related deterioration leads to component wear and breakdown.

Chemical leakage results in corrosion and short-circuiting, and improper handling or contamination can also cause damage.

Environmental factors, such as heat, humidity, and foreign debris, can lead to warping and damaged soldered joints.

What Are the Failure Modes of Printed Circuit Boards?

Failure modes of printed circuit boards encompass a range of defects, including soldering issues, mechanical damage, contamination, dimensional inaccuracies, and plating flaws. These defects can lead to electrical shorts, open circuits, and poor aesthetics, ultimately resulting in complete PCB failure.

Understanding the various failure modes is vital for implementing effective quality control measures to guarantee the reliability and performance of printed circuit boards.