Measuring the water absorption rate in PCB laminates is essential for ensuring the reliability and performance of electronic components, as excessive moisture absorption can compromise the material's integrity, leading to electrical shorts, corrosion, and delamination. The water absorption rate impacts PCB laminate performance, mechanical and electrical properties, and material durability. Standardized test methods, such as ASTM D 570-57T, are employed to measure water absorption behavior. Understanding the water absorption rate is vital for material selection, PCB design, and manufacturing processes. By exploring further, you can uncover the intricacies of water absorption in PCB laminates and its significance in ensuring the reliability of electronic systems.

Key Takeaways

- The ASTM D 570-57T test method measures water absorption rate in PCB laminates by quantifying weight gain over immersion time.

- Gravimetric Analysis provides a quantitative assessment of moisture absorption, helping evaluate long-term performance and reliability.

- The Weight Gain Method is a common technique for measuring water absorption rate, assessing a material's ability to absorb moisture.

- Accurate measurement of water absorption rate is crucial, as high absorption rates can compromise mechanical, electrical, and chemical properties.

- Understanding water absorption behavior is essential for selecting suitable PCB laminate materials and ensuring reliability in humid environments.

Importance of Water Absorption Rate

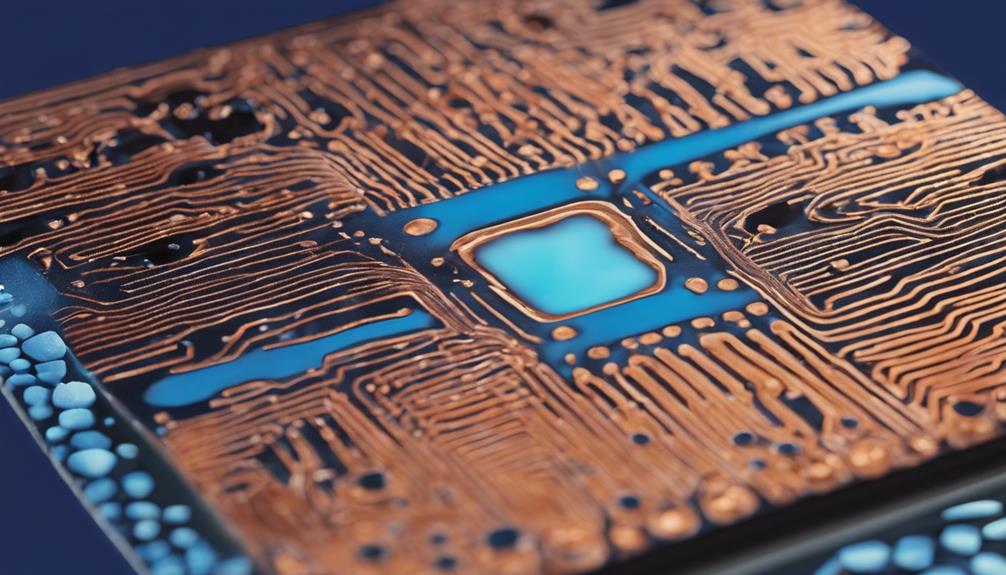

The water absorption rate of PCB laminates is an important material property that has a profound impact on the overall performance and reliability of printed circuit boards in various applications. Moisture absorption, a critical aspect of water absorption rate, greatly affects the mechanical, electrical, and chemical properties of PCB laminates. A high water absorption rate can compromise the material's integrity, leading to reduced performance and durability. Conversely, low water absorption rates are essential for maintaining the performance and durability of PCB laminates in various applications.

The importance of water absorption rate lies in its ability to determine the material's vulnerability to moisture, which is an important factor in PCB laminate selection.

Understanding the water absorption rate of PCB laminates is crucial in ensuring the reliability and performance of printed circuit boards. The ASTM D 570-57T test method is commonly used to measure water absorption rates in PCB laminates, taking into account factors such as immersion time and temperature, which greatly influence the water absorption rate. By measuring and controlling water absorption rates, manufacturers can guarantee the production of high-quality PCB laminates that meet the demands of various applications.

Copper Clad Laminate Properties

When analyzing copper clad laminate properties, it is essential to take into account the thermal expansion coefficient and its impact on water absorption rates.

The thermal expansion coefficient, which varies among laminate materials, influences the laminate's susceptibility to moisture absorption and subsequent electrical and mechanical property degradation.

Understanding these effects is important for accurately measuring water absorption rates in PCB laminates.

Thermal Expansion Coefficient

Copper clad laminates exhibit unique thermal expansion coefficients, a critical property that greatly influences their dimensional stability during temperature fluctuations. The thermal expansion coefficient, a measure of how much a material changes in size in response to temperature changes, has a substantial impact on the reliability of electronic devices.

Different laminate materials possess varying expansion coefficients, making some more suitable for specific applications than others. For instance, copper clad laminates with lower thermal expansion coefficients are preferred for high precision electronic devices, where dimensional stability is paramount.

Understanding the thermal expansion properties of PCB laminates is essential for designing reliable electronic systems. Manufacturers consider the coefficient of thermal expansion when selecting copper clad laminates to guarantee proper performance in varied environments.

A thorough understanding of this critical property enables the development of robust and efficient electronic systems. By recognizing the importance of thermal expansion coefficients, manufacturers can optimize their design and material selection, ultimately enhancing the overall performance of electronic devices.

Moisture Absorption Effects

In addition to thermal expansion, another important aspect of copper clad laminate properties is moisture absorption, which can greatly impact the mechanical, electrical, and chemical properties of printed circuit boards.

Moisture absorption in PCB laminates can have a profound effect on their performance and reliability, making it a vital factor to take into account in their design and application.

The ASTM D 570-57T test method is commonly used to measure the water absorption rate in PCB laminates, providing valuable insights into their moisture absorption properties. However, it is essential to note that different laminate formulations can result in varying interpretations of weight increase due to water absorption, highlighting the need for careful consideration of laminate selection.

Factors such as immersion time and temperature play a crucial role in determining the water absorption rate of PCB laminates. Low moisture absorption is essential for maintaining the performance and reliability of PCB laminates in various applications.

Measuring Water Absorption Methods

Measuring water absorption in PCB laminates requires precise methods to determine the rate of water uptake. This can be achieved through various techniques, including the Weight Gain Method, Gravimetric Analysis Method, and Thermogravimetric Analysis.

Each of these methods provides a distinct approach to quantify water absorption, enabling the accurate assessment of laminate performance.

Weight Gain Method

Accurate assessment of a printed circuit board (PCB) laminate's propensity for water absorption is facilitated by the weight gain method, a widely employed technique for quantifying moisture absorption in these materials. This method involves calculating the percentage increase in weight of the PCB laminate after exposure to water, providing a direct measure of water absorption.

By tracking the weight gain over time, the weight gain method helps assess the material's ability to absorb moisture, which is essential for evaluating the laminate's suitability for specific applications. The results from this method provide critical data for evaluating the laminate's long-term performance and reliability.

As measuring water absorption rate in PCB laminates is necessary for predicting reliability, the weight gain method plays an important role in ensuring the quality and durability of PCBs. By accurately quantifying moisture absorption, manufacturers can make informed decisions about material selection, design, and manufacturing processes, ultimately leading to improved product performance and customer satisfaction.

Gravimetric Analysis Method

One of the most widely employed methods for measuring water absorption in PCB laminates is gravimetric analysis, which provides a quantitative assessment of moisture absorption through precise weight measurements.

This method involves weighing the laminate before and after exposure to water, allowing for the calculation of the weight gain due to moisture absorption. The water absorption rate is then calculated by dividing the weight gain by the initial weight of the laminate.

Gravimetric analysis provides quantitative data on how much moisture the PCB laminate absorbs, enabling the assessment of the impact of water absorption on the properties and performance of the laminate. Under controlled moisture pressure, the laminate is exposed to water, and the weight measurements are taken at regular intervals.

This method is particularly useful in evaluating the effects of water absorption on the laminate's electrical and mechanical properties. By providing accurate and reliable data, gravimetric analysis is a valuable tool in the development of PCB laminates with improved moisture resistance.

Thermogravimetric Analysis

Thermogravimetric analysis (TGA) offers a complementary approach to gravimetric analysis, enabling the assessment of water absorption rates in PCB laminates under controlled temperature conditions. This method involves subjecting the PCB laminate to controlled temperature increases while monitoring weight changes. As water absorption occurs, it results in weight gain in PCB laminates, affecting their properties and performance.

TGA provides valuable insights into the moisture absorption behavior of different laminate formulations. By accurately measuring the weight changes, TGA data helps in understanding the water absorption rate of PCB laminates. This information is essential for ensuring the reliability and durability of PCB laminates.

The controlled temperature conditions in TGA allow for a more thorough understanding of the water absorption process, enabling the identification of ideal laminate formulations for specific applications. By leveraging TGA, manufacturers can optimize their PCB laminate designs to minimize the impact of water absorption, ultimately enhancing the overall performance and lifespan of their products.

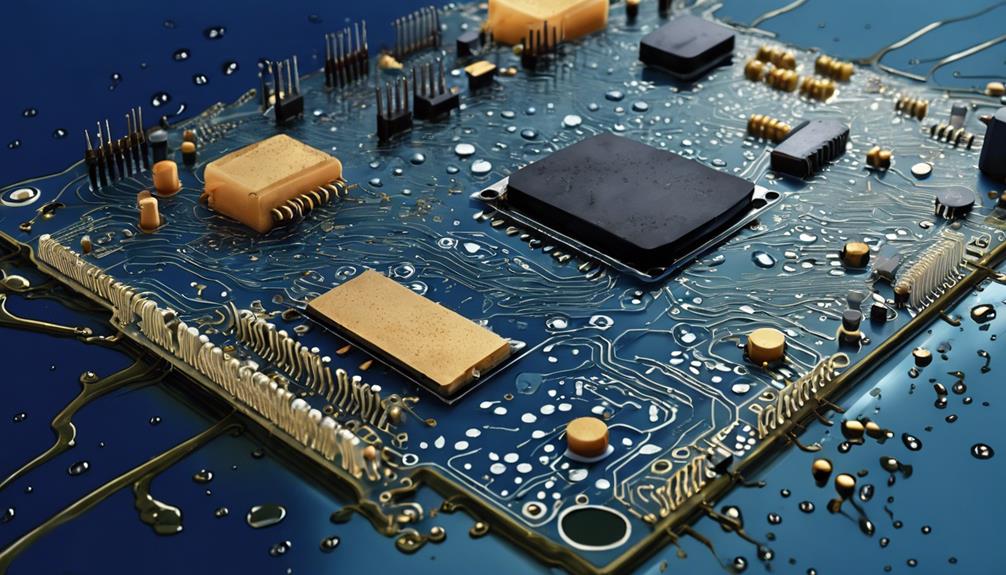

Effects on Electronic Component Reliability

In the presence of absorbed water, the reliability of electronic components mounted on PCB laminates can be severely compromised, leading to premature failure or degradation of the entire system. This is because water absorption can lead to a range of detrimental effects, including:

- Corrosion of conductive paths and components

- Delamination of the laminate, resulting in electrical shorts

- Degradation of the laminate's chemical resistance, allowing further water ingress

- Increased risk of electrochemical migration

- Reduced thermal conductivity, leading to overheating and further component degradation

The effects of water absorption on electronic component reliability can be far-reaching and devastating.

Therefore, it is essential to ensure that PCB laminates exhibit low water absorption rates, thereby maintaining their mechanical, electrical, and chemical properties. By doing so, manufacturers can minimize the risk of premature component failure and ensure the long-term reliability of their electronic systems.

Moisture Ingress Detection Techniques

Moisture ingress detection techniques are essential for evaluating the water absorption rate in PCB laminates. Two prominent methods used for detecting moisture ingress are the Gravimetric Analysis Method and the Electrical Property Shift method.

These techniques enable the accurate measurement of moisture absorption rates, which is critical for ensuring the reliability and performance of PCBs.

Gravimetric Analysis Method

By tracking the incremental weight gain of PCB laminates exposed to controlled humidity environments, gravimetric analysis provides a reliable means of quantifying water absorption rates. This method is commonly used to measure moisture absorption in PCB laminates, as it allows for accurate tracking of weight changes over time. The data obtained from gravimetric analysis is essential in evaluating the performance of laminates in humid environments.

The advantages of gravimetric analysis include:

- High accuracy in measuring water absorption rates

- Non-destructive testing method

- Ability to detect subtle changes in laminate properties

- Cost-effective compared to other moisture detection methods

- Provides valuable insights into laminate performance in humid environments

Electrical Property Shift

Electrical property shifts in PCB laminates, triggered by the ingress of moisture, can greatly impact the reliability and performance of electronic devices, making timely detection essential for preventing malfunctions.

Moisture ingress can alter the electrical properties of PCB laminates, leading to changes in capacitance, insulation resistance, and dielectric strength. These shifts can compromise the functionality of electronic components, resulting in faulty operation or complete failure.

To mitigate these risks, it is important to detect moisture ingress and monitor electrical property shifts in real-time. This can be achieved through various moisture ingress detection techniques, including the measurement of electrical properties such as impedance, capacitance, and resistance.

By tracking these parameters, manufacturers can identify potential failures and take preventive measures to ensure the reliability and durability of their products.

Understanding electrical property shifts is crucial for improving the performance and longevity of PCB laminates in various applications.

PCB Material Selection Criteria

When selecting PCB materials, a thorough evaluation of various factors is important to guarantee top performance in diverse environments. Understanding the water absorption rate in PCB laminates is essential for choosing materials that can withstand environmental stresses and maintain peak performance.

To secure long-term reliability, manufacturers must carefully consider the following key factors:

- Dielectric constant: affects signal speed and impedance

- Thermal conductivity: influences heat dissipation and component reliability

- Moisture absorption rate: impacts material durability and electrical performance

- Mechanical strength: determines PCB's resistance to physical stress

- Chemical resistance: affects material compatibility with various solvents and cleaning agents

Water Absorption Test Procedures

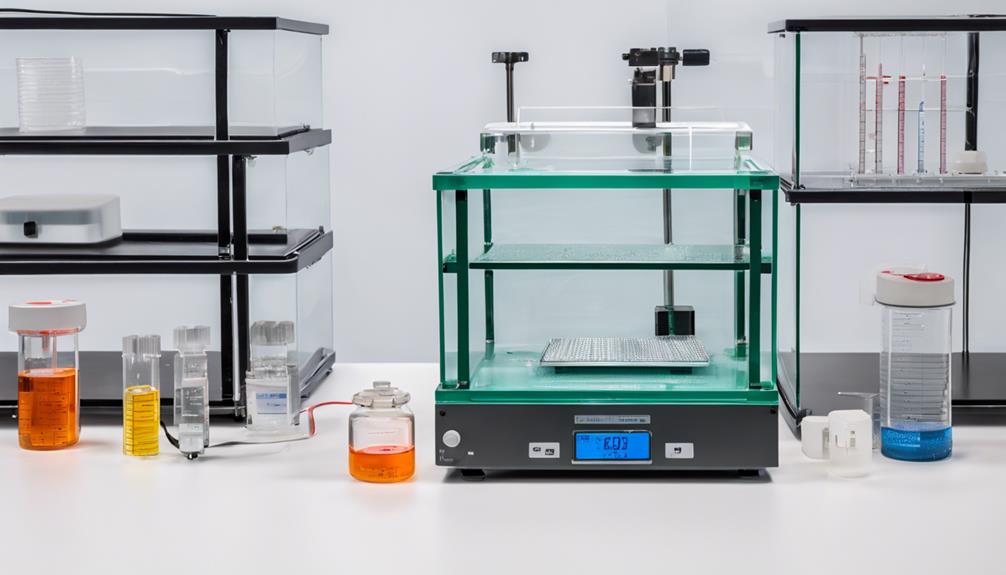

Measuring water absorption rates in PCB laminates necessitates a standardized approach, with the ASTM D 570-57T test method being the most commonly employed procedure to determine the material's susceptibility to moisture ingress. This test method involves conditioning specimens in a controlled environment, followed by immersion in water, and subsequent measurement of weight gain due to moisture absorption.

The ASTM D 570-57T method provides a reliable means of evaluating the moisture absorption characteristics of different laminate formulations, which is essential for maintaining the mechanical, electrical, and chemical properties of PCB laminates. Factors such as immersion time and temperature can influence the water absorption rate, and thus, must be carefully controlled during testing.

Understanding Water Absorption Behavior

The water absorption behavior of PCB laminates, characterized by the rate and extent of moisture ingress, profoundly influences their performance and reliability in various industrial applications. Understanding this behavior is essential for ensuring the durability and reliability of PCB laminates.

The chemical properties of PCB laminates play a significant role in determining their water absorption behavior. Factors such as immersion time and temperature can have a notable impact on the water absorption rate, leading to varying interpretations of weight increase due to water absorption. Different laminate formulations can also result in distinct water absorption behaviors.

Some key aspects of water absorption behavior in PCB laminates include:

- The impact of water absorption on mechanical, electrical, and chemical properties

- The role of immersion time and temperature on water absorption rate

- The effect of laminate formulations on water absorption behavior

- The importance of low water absorption for ensuring durability and reliability

- The use of standardized test methods, such as ASTM D 570-57T, to measure water absorption behavior

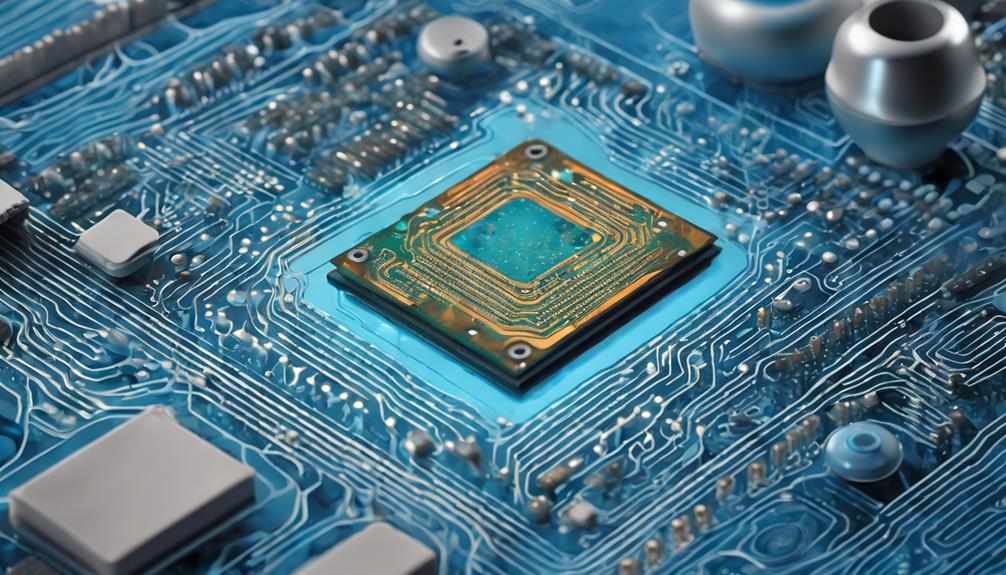

PCB Design Considerations for Moisture

PCB designers must consider the potential for moisture ingress and its impact on laminate performance when developing board layouts and selecting materials. The moisture absorption rate in PCB laminates can greatly affect the overall performance and reliability of the printed circuit board.

To mitigate this, designers can employ design considerations such as copper plane meshing to inhibit moisture travel between layers. This is essential, as water absorption in PCBs can compromise mechanical, electrical, and chemical properties essential for their performance.

Immersion time and temperature are critical factors influencing the water absorption rate of PCB laminates. Hence, designers should carefully select materials and design layouts that minimize moisture absorption. Low moisture absorption is crucial for ensuring the durability and reliability of PCBs in various applications.

Material Properties and Water Absorption

When examining the material properties of PCB laminates, it is essential to understand the mechanisms of water uptake, as different laminate material classes exhibit varying levels of moisture absorption.

The rate of moisture diffusion through the laminate material plays a critical role in determining the overall water absorption rate. By understanding these factors, designers and manufacturers can select materials that minimize water absorption, ensuring the reliability and integrity of PCBs in diverse applications.

Water Uptake Mechanisms

Material properties, such as resin type and fiber content, greatly influence the water uptake mechanisms in PCB laminates, leading to varying levels of water absorption. The water absorption rate in PCB laminates is a critical factor in determining their performance in humid environments.

The water uptake mechanisms in PCB laminates can be attributed to the following factors:

- Diffusion through resin matrix: Water molecules penetrate the resin, leading to swelling and degradation of the laminate.

- Capillary action along fiber reinforcements: Water seeps into the gaps between fibers, causing delamination and dimensional changes.

- Surface finish: The type of surface finish can either enhance or hinder water absorption, depending on its hydrophobic or hydrophilic nature.

- Fiber content and orientation: The type and orientation of fibers can affect the rate of water absorption and diffusion.

- Interfacial interactions: The interaction between the resin and fibers can influence the water uptake mechanisms, leading to varying levels of water absorption.

Understanding these water uptake mechanisms is essential for designing PCB laminates with optimal water absorption rates, ensuring reliable performance in humid environments.

Laminate Material Classes

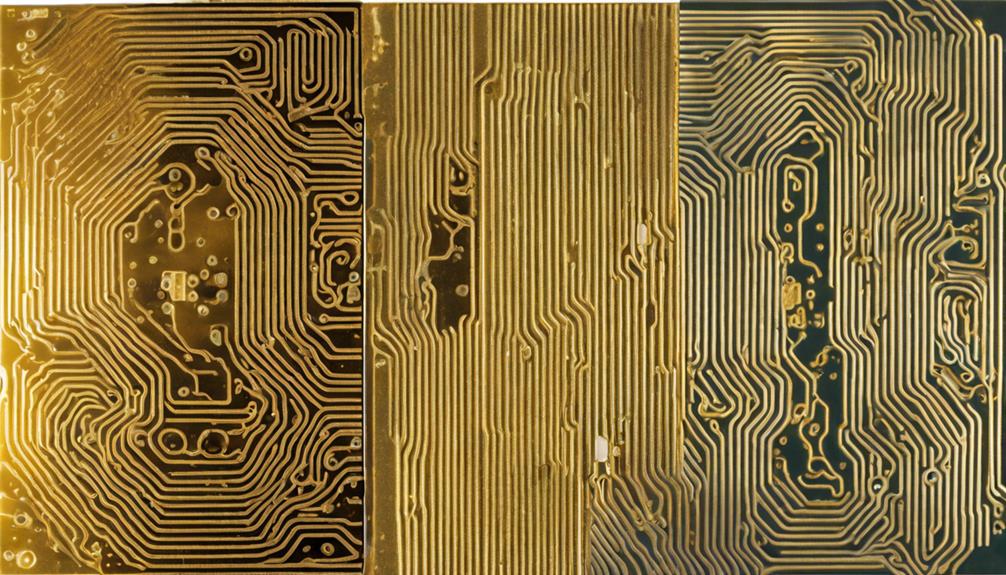

The diverse range of laminate material classes, each with its unique composition, exhibits distinct water absorption characteristics that greatly impact PCB performance. The water absorption rates of these materials vary substantially, depending on their composition.

For instance, FR-4 laminates, commonly used in PCBs, have a water absorption rate ranging from 0.15% to 0.17% after 24 hours of immersion. In contrast, other laminate material classes, such as FR-3 and CEM-1, exhibit different water absorption rates due to their distinct compositions.

Understanding the water absorption properties of laminate materials is essential for designing moisture-resistant PCBs. High water absorption rates in laminates can compromise mechanical and electrical properties, ultimately impacting PCB performance. Different laminate material classes have specific water absorption characteristics, influencing their suitability for diverse PCB applications.

Moisture Diffusion Rates

In addition to their distinct water absorption rates, laminate materials exhibit unique moisture diffusion rates that greatly impact PCB performance. The rate at which moisture diffuses through a laminate material can have a significant effect on its electrical and mechanical properties. This is particularly important in applications where PCBs are exposed to humid or wet environments.

Moisture diffusion rates vary among laminate materials, and understanding these rates is essential for selecting the right material for a specific application. Factors such as immersion time, temperature, and material properties influence the moisture diffusion rate.

Some key aspects of moisture diffusion rates in PCB laminates include:

- The rate of moisture diffusion affects the material's electrical insulation properties

- Moisture diffusion can lead to delamination, reducing the material's mechanical properties

- The diffusion rate influences the material's susceptibility to corrosion

- Material properties, such as density and porosity, impact the moisture diffusion rate

- Temperature and humidity levels significantly affect the diffusion rate

Water Absorption Rate Measurement Tools

Characterizing water absorption in PCB laminates relies on employing precise measurement tools that can accurately detect subtle changes in weight and dimensional stability. The ASTM D570-57T test method is commonly used to measure water absorption rates in PCB laminates. This method involves immersing the laminate in water and measuring the weight increase over time. The specific laminate formulation, immersion time, and temperature all influence the measurement results.

| Measurement Tool | Description |

|---|---|

| ASTM D570-57T | Standard test method for water absorption of plastics |

| Gravimetric analysis | Measures weight increase due to water absorption |

| Dimensional analysis | Measures changes in laminate dimensions |

| Environmental chambers | Controls temperature and humidity for precise measurements |

| Data loggers | Records weight and dimensional changes over time |

Accurate measurement of water absorption rates is essential for ensuring the long-term performance and reliability of PCB laminates. When PCB laminates absorb moisture when they're packaged, it can lead to compromised mechanical, electrical, and chemical properties. By employing precise measurement tools, manufacturers can optimize laminate formulations and processing conditions to minimize water absorption rates, ensuring high-performance PCBs.

Assessing Water Absorption in PCBs

Accurate assessment of water absorption in PCBs is essential to guarantee the long-term reliability and performance of these critical components. Water absorption can greatly impact the mechanical, electrical, and chemical properties of PCB laminates, making it vital to measure and control this parameter.

To assess water absorption in PCBs, several factors must be considered:

- Immersion time and temperature: These factors greatly influence the rate of water absorption in PCB laminates.

- Laminate formulation: Different formulations can lead to varying interpretations of weight increase due to water absorption.

- Moisture exposure: PCBs are susceptible to moisture when they're packaged, which can affect their performance and reliability.

- ASTM D 570-57T test method: This standardized test method is commonly used to measure water absorption in PCB laminates.

- Low water absorption: This is essential for maintaining the performance and reliability of PCB laminates in various applications.

Moisture Protection Strategies for PCBs

What measures can be taken to protect PCBs from the detrimental effects of moisture, and how do these strategies mitigate the risks associated with water absorption?

Moisture protection strategies for PCBs are vital to prevent electrical short circuits and corrosion, guaranteeing long-term reliability and performance.

Moisture-resistant materials and sealing techniques are commonly employed to safeguard PCBs from moisture ingress. By using these strategies, PCB manufacturers can minimize the risks associated with high water absorption rates, which can lead to dimensional changes and degradation of insulation properties.

Proper moisture protection is essential to prevent electrical short circuits and corrosion, ensuring the dependable operation of PCBs in various environments.

Effective moisture protection strategies involve a combination of material selection, design considerations, and manufacturing processes. By understanding the water absorption rate in PCB laminates, manufacturers can develop targeted strategies to mitigate the risks associated with moisture exposure.

IPC Standards for Water Absorption

To ensure the reliability and performance of printed circuit boards (PCBs) in diverse environments, adherence to industry standards for water absorption in PCB laminates is vital, and IPC standards provide a framework for evaluating and controlling water absorption rates.

IPC standards specify acceptable water absorption rates for PCB laminates, ensuring that they meet industry requirements. The standards outline testing methods to determine water absorption properties, which impact the mechanical and electrical performance of PCB laminates. Compliance with IPC standards is essential for quality control in PCB laminate manufacturing.

Key aspects of IPC standards for water absorption include:

- Specifying acceptable water absorption rates for PCB laminates

- Outlining testing methods to determine water absorption properties

- Ensuring compliance with industry requirements

- Impacting mechanical and electrical performance of PCB laminates

- Providing a framework for quality control in PCB laminate manufacturing

Enhancing PCB Reliability With Water Absorption Testing

Enhancing PCB reliability becomes a critical concern when water absorption testing reveals the vulnerabilities of laminates to moisture-related issues.

The ASTM D 570-57T test method provides a standardized approach to measuring water absorption rates, which is essential for evaluating the reliability and performance of PCBs.

Moisture absorption can compromise the mechanical, electrical, and chemical durability of PCB laminates, making it vital to understand water absorption rates.

Factors such as immersion time and temperature have a substantial impact on the water absorption characteristics of PCB laminates, and low water absorption rates are essential for ensuring the durability of these components.

By conducting water absorption testing, manufacturers can identify vulnerabilities and optimize their designs to minimize the risk of moisture-related failures.

By doing so, they can enhance PCB reliability, reducing the likelihood of premature failure and ensuring top-notch performance.

Frequently Asked Questions

How to Measure Moisture Absorption?

To accurately measure moisture absorption, a controlled environment is crucial. Utilize a precise weighing method, such as a analytical balance, to quantify weight gain.

Maintain consistent immersion conditions, including temperature and time, to minimize variability. ASTM D 570-57T provides a standardized protocol for measuring water absorption, which involves immersing the material in distilled water at a controlled temperature, followed by periodic weighing to calculate the weight gain percentage.

What Is the Absorption of FR-4 in Water?

The absorption of FR-4 in water is a critical parameter in maintaining PCB performance and reliability. FR-4, a widely used PCB laminate, exhibits a water absorption rate of approximately 0.15% to 0.2% by weight.

This absorption occurs primarily through exposed edges and cutouts, leading to changes in electrical properties and dimensional stability. Understanding this absorption behavior is essential for optimizing PCB design and ensuring reliable performance in various environmental conditions.

What Is the Moisture Sensitivity Level of a Pcb?

The age-old question: what is the moisture sensitivity level of a PCB?

It's not as if our precious PCBs are delicate flowers that wilt in the presence of moisture. Alas, they do.

In reality, the Moisture Sensitivity Level (MSL) of a PCB determines its susceptibility to moisture-induced damage. Ranging from 1 to 6, higher MSL ratings indicate greater sensitivity, necessitating stringent handling and storage to prevent failures.

Understanding MSL requirements is vital for ensuring PCB assembly quality and longevity.

What Is the Formula for Water Absorption?

The formula for water absorption is a critical calculation in evaluating a material's susceptibility to moisture.

The formula is:

Water Absorption (%) = [(Wet Weight – Dry Weight) / Dry Weight] x 100.

This calculation determines the percentage increase in weight due to water absorption, providing a precise measure of a material's moisture sensitivity.

This formula is essential in designing reliable electronic applications, particularly in harsh environmental conditions.