Copper clad laminates, widely used in printed circuit boards (PCBs), exhibit varying dielectric constant values depending on material composition, frequency, and thickness, which greatly impact signal integrity, impedance matching, and overall PCB performance. Dielectric constant values range from 3.3 to 4.8, influenced by laminate material composition and frequency-dependent behavior. Accurate control of dielectric constant values is essential for optimizing PCB designs. As frequency and thickness variations affect dielectric constant values, understanding these factors is important for material selection and high-frequency PCB design. Further exploration reveals the importance of thermal, electrical, and hygroscopic properties in copper clad laminates.

Key Takeaways

- FR4 laminates have dielectric constant values ranging from 3.3 to 4.8, influencing electrical properties and PCB performance.

- Dielectric constant values vary across different frequencies in copper-clad laminates, affecting signal integrity in high-speed designs.

- Thickness variations in copper clad laminates impact dielectric constant values, signal propagation, and impedance characteristics.

- Accurate control of dielectric constant values is crucial for optimizing PCB designs, especially in high-frequency applications.

- Different materials offer specific dielectric constant ranges for tailored solutions, making material selection critical for high-frequency performance.

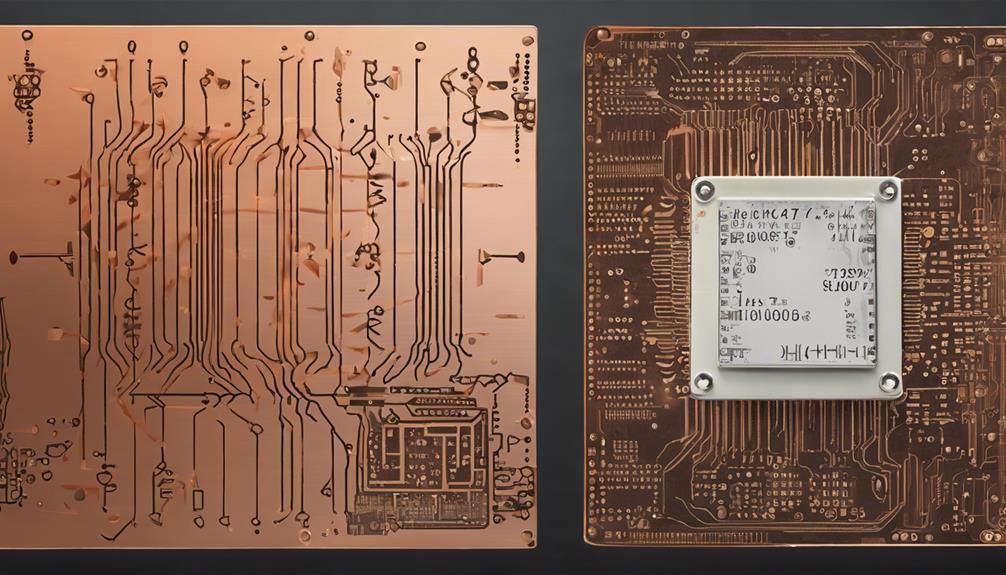

Copper Clad Laminate Material Options

Copper clad laminate material options encompass a diverse range of substrate formulations, each tailored to address specific demands in printed circuit board (PCB) design and manufacturing. The selection of a suitable laminate material is essential, as it directly influences the electrical properties, thermal properties, and overall performance of the PCB.

In the domain of high-frequency applications, laminate materials with low dielectric constants are preferred to minimize signal attenuation. Conversely, low-cost laminate options may be suitable for non-critical PCB designs.

FR4 laminates, a popular choice in the PCB industry, offer a reliable balance between electrical properties, thermal properties, and cost. They exhibit a dielectric constant ranging from 3.3 to 4.8, ensuring reliable insulation properties and a breakdown field strength of approximately 20 kV/mm. With varying glass transition temperatures and a UL94-V0 flammability rating, FR4 laminates cater to diverse PCB requirements.

Dielectric Constant Value Ranges

The dielectric constant value ranges of copper clad laminates are influenced by various material properties, which can impact the laminate's performance in different frequency ranges.

The subsequent discussion will explore how material properties, frequency dependence, and thickness variations affect the dielectric constant values, ultimately affecting the overall performance of the laminate.

Material Property Effects

Within the domain of copper clad laminates, the dielectric constant value ranges are greatly influenced by various material properties. The material composition of the laminate, including the type and amount of resin used, has a substantial impact on the dielectric constant value.

For instance, FR4 laminate dielectric constant values typically range from 3.3 to 4.8, depending on factors like weave style and resin content. In contrast, high-performance materials like PTFE can offer lower dielectric constant values compared to standard FR4 laminates.

The dielectric constant of copper clad laminates plays a critical role in signal integrity in high-speed PCB designs, as it affects impedance matching and overall circuit performance. Variations in dielectric constant values can have a significant impact on the performance of high-speed circuits, underscoring the importance of accurate measurement and control of dielectric constant values for optimizing PCB designs.

Frequency Dependence Range

Across a wide range of frequencies, the dielectric constant values of copper-clad laminates exhibit a notable variation, underscoring the importance of understanding their frequency-dependent behavior in high-speed PCB designs.

This frequency-dependent range has a noteworthy impact on signal integrity considerations, as variations in dielectric constant values can affect the performance of electronic circuits. Accurate knowledge of dielectric constant value ranges is essential for material selection in specific applications, where the wrong choice can lead to compromised performance.

The dielectric constant values of different copper-clad laminates can vary significantly within a specific frequency range, making it essential to understand their frequency-dependent behavior. This understanding is critical in high-speed PCB designs, where signal integrity considerations are paramount.

Thickness Variation Impact

Copper clad laminate thickness variations greatly impact dielectric constant values, which in turn affect signal propagation and impedance characteristics in high-speed PCB designs. The dielectric constant values for copper clad laminates can vary based on thickness, with typical ranges spanning from 3.3 to 4.8. Thicker copper clad laminates tend to exhibit higher dielectric constants within the specified range due to increased material volume.

| Thickness (mm) | Dielectric Constant Range | Material Volume |

|---|---|---|

| 0.5 | 3.3-3.8 | Low |

| 1.0 | 3.5-4.2 | Medium |

| 1.5 | 3.8-4.5 | High |

| 2.0 | 4.0-4.8 | Very High |

Understanding the dielectric constant variations in copper clad laminates is essential for high-speed PCB designs requiring precise signal integrity and impedance control. Dielectric constant values in copper clad laminates play a significant role in determining the electrical performance and overall functionality of printed circuit boards. By recognizing the impact of thickness variation on dielectric constant values, designers can enhance their PCB designs for top-notch electrical performance.

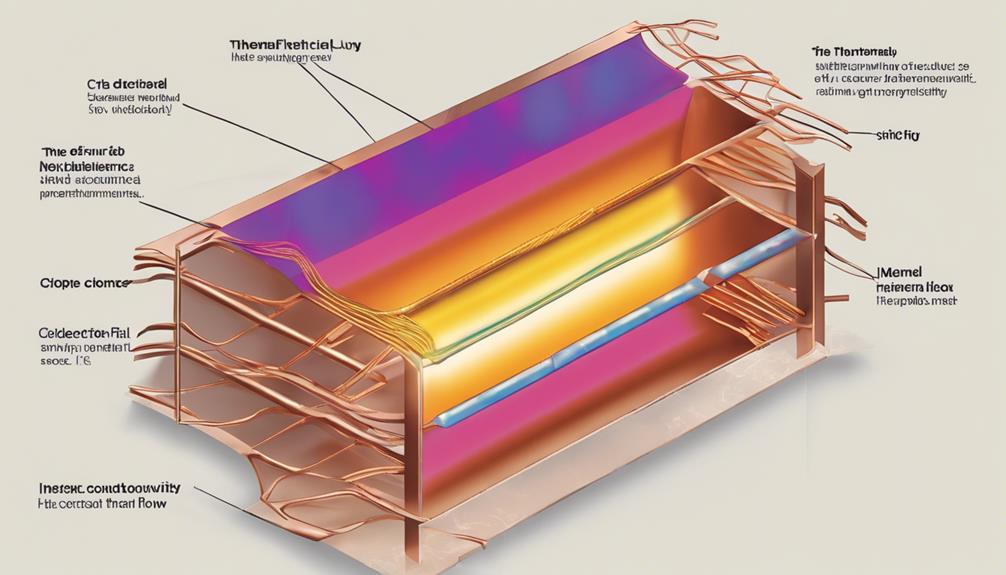

Thermal and Electrical Properties

In the domain of thermal and electrical properties, copper clad laminates exhibit a distinct set of characteristics that are critical to understanding their performance in printed circuit board (PCB) applications. The thermal conductivity of these laminates, which is influenced by factors such as resin content and material composition, plays a key role in heat dissipation.

With regards to dielectric properties, copper clad laminates display a dielectric constant (Dk) range of 3.3 to 4.8, making them suitable for various PCB applications. FR4 laminates, a common type of copper clad laminate, offer a standard thickness of 1.57 mm and a flammability rating of UL94-V0. These laminates also exhibit a glass temperature (Tg) of around 130°C for low-Tg variants and approximately 170°C for high-Tg variants.

The breakdown field strength of approximately 20 kV/mm highlights their electrical insulation capability. Understanding these thermal and electrical properties is essential for designing reliable and efficient PCBs. By considering these characteristics, designers can optimize their PCB designs and ensure top-notch performance.

Chemical Properties and Moisture Absorption

When evaluating the chemical properties of copper clad laminates, it is essential to take into account the impact of chemical structure on dielectric constant values.

The rate of moisture absorption and hygroscopic properties of these materials also play a critical role in determining their suitability for specific PCB applications.

Chemical Structure Impact

The dielectric constant of copper clad laminate materials is greatly influenced by their chemical structure, which can be tailored through the strategic selection of resin types and additives. This chemical structure has a substantial impact on the dielectric constant values, ultimately affecting signal integrity in PCB applications. Variations in chemical composition can alter the dielectric constant of laminates, leading to unstable signal transmission.

Different resin types and additives play an important role in determining the dielectric constant of copper clad laminates. By understanding the chemical properties of laminates, manufacturers can control moisture absorption, which can alter dielectric constant values. Monitoring moisture absorption levels is essential to maintain stable dielectric constant values in copper clad laminate materials.

This is particularly important in PCB applications, where signal integrity relies on a stable dielectric constant. By optimizing the chemical structure of copper clad laminates, manufacturers can ensure reliable signal transmission and maintain the integrity of their PCB applications.

Moisture Absorption Rate

Moisture absorption rate, an essential factor influencing dielectric material performance, greatly impacts the reliability and stability of copper clad laminates in PCB applications. The ability of a dielectric material to absorb moisture greatly affects its dielectric constant, leading to signal degradation and fluctuations in performance reliability. A low moisture absorption rate is vital for maintaining stable dielectric properties, guaranteeing long-term functionality in PCB applications.

| Material Type | Moisture Absorption Rate (%) |

|---|---|

| FR4 | 0.15 – 0.30 |

| FR5 | 0.10 – 0.20 |

| Polyimide | 0.05 – 0.15 |

Proper evaluation of moisture absorption rates is critical in selecting suitable dielectric materials for specific PCB design requirements. By understanding the moisture absorption characteristics of copper clad laminate materials, designers can secure the reliable performance of their PCBs over time. The table above illustrates the varying moisture absorption rates of different material types, highlighting the importance of material selection in maintaining stable dielectric properties.

Hygroscopic Properties

Inherent to copper clad laminates is a propensity to absorb moisture, a characteristic that greatly impacts their dielectric properties and overall performance in PCB applications. This hygroscopic property is an important aspect of laminate behavior, as it directly affects signal integrity and reliability.

Moisture absorption can alter the dielectric constant, leading to unpredictable electrical characteristics and compromised signal integrity. Consequently, copper clad laminates with low moisture absorption rates are preferred for high-performance applications, where stable electrical characteristics are paramount.

Understanding the hygroscopic properties of laminates is essential for maintaining reliable performance over time. Manufacturers specify moisture absorption levels to guarantee the reliability and performance of copper clad laminates. By controlling moisture absorption, manufacturers can ensure stable electrical characteristics, essential for high-performance applications.

In these demanding environments, even slight variations in dielectric constant can have significant consequences. Therefore, a thorough understanding of hygroscopic properties is crucial for optimizing laminate performance and ensuring the reliability of PCBs in high-stress applications.

High-Frequency Material Selection Guide

For ideal high-frequency performance, selecting materials with suitable dielectric constant values is essential, as they directly impact signal integrity and loss.

A high-frequency material selection guide is important in choosing dielectric materials with low dielectric constant values, which are critical for best signal transmission.

Dielectric constant values play a significant role in signal integrity and high-frequency performance, making it important to understand their impact on high-speed PCBs.

Best material selection ensures minimal signal loss and efficient high-frequency operation.

Different materials offer specific dielectric constant ranges, allowing for tailored high-frequency solutions.

By understanding dielectric constant values, designers can create high-speed PCBs for various applications, ensuring reliable and efficient signal transmission.

A detailed material selection guide aids in handling the complexities of dielectric materials, enabling designers to make informed decisions for excellent high-frequency performance.

PCB Design Implications and Considerations

When designing high-speed PCBs, the dielectric constant values of copper clad laminates must be carefully considered to mitigate signal degradation and guarantee peak performance. This is particularly vital in high-frequency applications where signal integrity and impedance control are paramount.

| Dielectric Material | Dielectric Constant (Dk) | Impedance Control |

|---|---|---|

| FR4 | 3.3-4.8 | Moderate |

| Low-Dk Material | 2.5-3.0 | High |

| High-Frequency Material | 2.0-2.5 | Excellent |

To ensure top-notch PCB performance, designers must adhere to PCB Design Guidelines that account for dielectric constant variations in laminates. This includes selecting dielectric materials with low Dk values to minimize insertion losses and guarantee controlled impedance. By doing so, high-speed design limitations can be overcome, and signal integrity can be maintained.

In high-frequency applications, impedance control is critical to prevent signal degradation. Accurate measurement and control of dielectric constant values are essential for optimizing PCB performance. By considering the dielectric constant values of copper clad laminates, designers can create high-performance PCBs that meet the demands of high-speed design.

Frequently Asked Questions

What Is the Value of the Dielectric Constant of Copper?

Importantly, 90% of electronic circuits rely on copper's exceptional conductivity. Regarding the dielectric constant of copper, it is approximately 1, which is markedly lower than that of insulating materials.

This low value indicates copper's limited ability to store electrical energy, making it an excellent conductor for efficient signal transmission. This property is vital for high-speed electronic circuits, as it minimizes signal loss and distortion.

What Is the Dielectric Constant of Copper Pcb?

The dielectric constant of a copper PCB, a critical parameter in printed circuit board design, typically falls within the range of 3.3 to 4.8.

This variability is attributed to factors such as weave style, resin content, and material composition.

Understanding the specific dielectric constant value is crucial for maximizing PCB performance, as it directly impacts signal integrity and electromagnetic interference.

Which PCB Material Has a High Dielectric Constant?

When selecting a PCB material, high dielectric constants are often desirable for controlled impedance and signal transmission properties.

Among various PCB materials, high-Tg FR4 laminates typically exhibit higher dielectric constants, ranging from 4.2 to 4.8.

Additionally, certain copper clad laminates are engineered to possess high dielectric constants, making them suitable for specific designs.

Rogers laminates, in particular, are known for their high dielectric constants, often exceeding 4.5.

What Is the Dielectric Properties of Copper?

'A bird in the hand is worth two in the bush,' emphasizing the importance of understanding copper's dielectric properties.

The dielectric constant of copper is approximately 1, a markedly low value compared to most dielectric materials.

This low dielectric constant is vital in minimizing signal loss and interference in high-frequency applications, contributing to improved signal integrity and high-speed performance in electronic circuits.