When designing high-speed circuits, selecting the essential material is vital to guarantee signal integrity, minimize signal loss, and maintain consistent electrical performance. Thermoset hydrocarbon laminates, such as Rogers 4350B and Megtron 6, offer low dielectric constants, controlled impedance, high thermal conductivity, and superior dimensional stability. These properties make them ideal for high-speed circuits. Alternative materials, such as polyimide and PTFE, also provide benefits for specific design requirements. By understanding the key properties required for best performance, designers can make informed material selections to ensure reliable and efficient high-speed circuit operation, and discover the most suitable material options for their specific design needs.

Key Takeaways

- Low dielectric constant (Dk) materials like Rogers 4350B and Megtron 6 minimize signal loss and maintain impedance consistency.

- Materials with high thermal conductivity and low thermal resistance, such as thermoset hydrocarbon laminates, enable efficient heat dissipation.

- Polyimide materials are suitable for harsh environments, while PTFE (Teflon) is preferred for high-frequency RF applications due to its low dielectric constant.

- Effective thermal management is crucial to prevent overheating, which can compromise signal integrity and damage components.

- Material selection should prioritize low dielectric constant, controlled impedance, and high thermal conductivity for optimal high-speed circuit performance.

Understanding High-Speed Circuit Requirements

High-speed circuits, where signal transmission rates surpass 100 MHz, require a precise set of material properties to guarantee reliable operation and minimal signal degradation. The selection of materials for high-speed circuit boards is critical, as it directly impacts signal integrity and overall performance.

A low dielectric constant (Dk) is essential to minimize signal loss at high frequencies, ensuring ideal signal transmission. Moreover, tight impedance control is necessary to maintain consistent electrical performance and prevent signal degradation. Effective thermal management is also vital, as high-speed circuits generate significant heat that can compromise performance and reliability. Materials with superior heat dissipation properties are crucial to prevent thermal-related issues.

Additionally, materials must exhibit mechanical stability, moisture resistance, and low dielectric loss factors to ensure reliable operation in varying environmental conditions. By understanding these requirements, designers and engineers can select materials that meet the stringent demands of high-speed circuits, ensuring excellent performance and reliability.

Key Properties for Optimal Performance

For peak performance in high-speed circuits, materials must possess a distinct set of properties that guarantee signal integrity, efficient heat dissipation, and mechanical stability.

When selecting high-speed PCB materials, a low dielectric constant (Dk) is essential to minimize signal loss and guarantee signal integrity. Controlled impedance is also critical, as it enables tight impedance control, resulting in consistent electrical performance in high-speed designs.

Thermal conductivity is another essential factor, as high thermal conductivity is necessary for efficient heat dissipation in high-speed circuits. This prevents overheating, which can compromise performance and reliability.

Superior dimensional stability is also important, ensuring mechanical integrity and reliable performance in high-speed circuits. Additionally, materials with moisture and chemical resistance are essential for stable operation of high-speed circuits, as they prevent degradation and ensure consistent performance over time.

Thermoset Hydrocarbon Laminates Benefits

Thermoset hydrocarbon laminates emerge as a preferred material choice for high-speed circuits due to their unique combination of advantageous properties. These laminates offer excellent dimensional stability, ensuring that the circuit design remains consistent and reliable. Additionally, they provide superior thermal management properties, efficiently dissipating heat and maintaining ideal operating temperatures.

| Property | Benefit | Advantage |

|---|---|---|

| Dimensional Stability | Consistent design | Reliable performance |

| Thermal Management | Efficient heat dissipation | Ideal operating temperatures |

| Low Loss Characteristics | Enhanced signal performance | Fast and accurate data transmission |

The low loss characteristics of thermoset hydrocarbon laminates enable high-speed circuits to achieve enhanced signal performance, ensuring fast and accurate data transmission. Moreover, these laminates allow for tight impedance control, resulting in consistent electrical performance. Their moisture and chemical resistance properties also contribute to the stable operation of high-speed circuits, making them an ideal material choice for demanding applications.

Alternative Material Options Compared

While thermoset hydrocarbon laminates offer an attractive combination of properties for high-speed circuits, alternative materials like Rogers 4350B and Megtron 6 have emerged as viable options, boasting low loss tangent and dielectric constant for demanding PCB designs.

These alternative materials are designed to address the limitations of traditional FR-4, providing superior electrical properties, stability, and reliability. Rogers 4350B, for instance, offers excellent high-frequency performance with a dielectric constant of approximately 3.48, making it an ideal choice for high-speed PCB designs.

Megtron 6, on the other hand, provides improved signal integrity and reduced signal loss with a dielectric constant of around 3.66. By choosing the right material, designers can minimize signal loss, maintain signal integrity, and optimize performance in high-speed circuits.

With their low loss tangent and dielectric constant, Rogers 4350B and Megtron 6 are well-suited for high-speed applications where signal integrity and reliability are paramount.

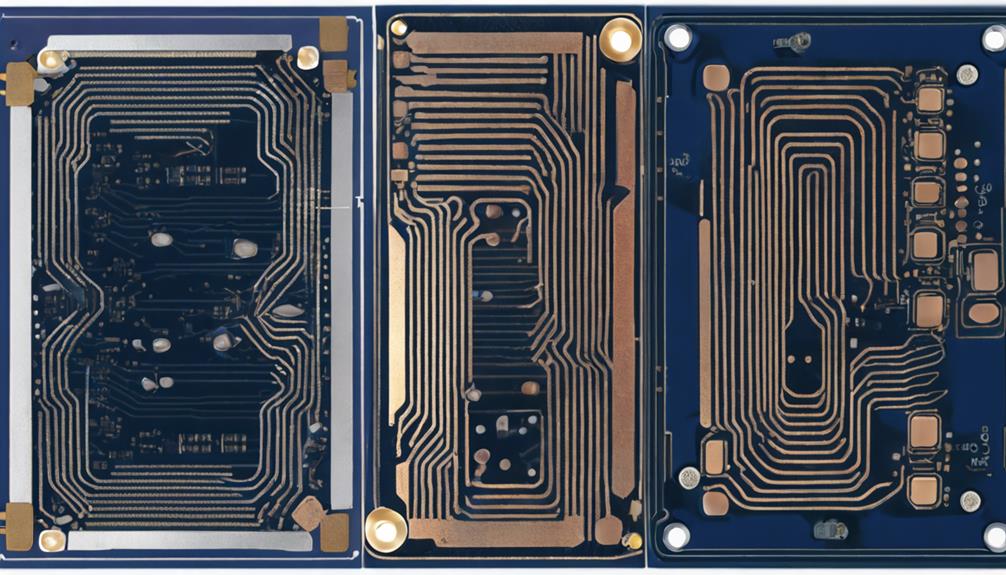

PCB Fabrication Material Options

Beyond the domain of alternative materials, the selection of PCB fabrication materials presents a diverse array of options, each tailored to address specific high-speed circuit requirements. When it comes to high-speed PCBs, the choice of material is critical.

Epoxy resins (FR-4) are a common choice, but they may not be ideal due to challenges in controlling impedance tightly, higher signal loss at high frequencies, limited mechanical stability, and higher moisture absorption. Enhanced epoxy materials, on the other hand, offer improved properties for high-speed designs.

Polyimide materials are suitable for harsh environments, while PTFE (Teflon) is preferred for high-frequency RF applications due to its low dielectric constant and dissipation factor. The selection of materials involves careful consideration of signal performance, durability, cost, controlled impedance concerns, thermal considerations, and exposure to different environments.

Material Selection for High-Speed Designs

When selecting materials for high-speed circuits, it is essential to take into account the intrinsic properties of the material, as they directly impact signal integrity and thermal management.

The material's dielectric properties, signal loss at operating frequencies, and resistance to environmental factors all play a critical role in maintaining signal integrity.

Material Properties Matter

The careful selection of materials for high-speed circuits is crucial, as the inherent properties of these materials greatly impact signal integrity and overall system performance. Material properties, such as dielectric constant and dissipation factor, are essential for guaranteeing signal integrity in high-speed circuits.

Selecting materials with low loss tangent and dielectric constant helps minimize signal loss and maintain reliable high-speed performance. Additionally, high-speed circuit materials should offer tight impedance control and superior thermal management for efficient signal transmission and heat dissipation.

Ideal materials exhibit dimensional stability, low loss, moisture resistance, and consistent impedance for reliable and efficient operation. It is important to take into account electrical, thermal, chemical, and mechanical properties when selecting materials for high-speed circuit applications.

Signal Integrity Impact

Material selection for high-speed circuits has a profound impact on signal integrity, as the inherent properties of the chosen material can greatly influence the reliability and efficiency of signal transmission. The dielectric constant (Dk) and dissipation factor (Df) of a material play significant roles in maintaining impedance consistency and minimizing signal loss.

| Material | Dielectric Constant (Dk) | Dissipation Factor (Df) |

|---|---|---|

| FR4 | 4.2-4.5 | 0.02-0.03 |

| Rogers 4350B | 3.48 | 0.0037 |

| Megtron 6 | 3.8 | 0.004 |

| Taconic TLX-8 | 3.9 | 0.0035 |

| Nelco N4000-13 | 3.9 | 0.0035 |

Premium materials like Rogers 4350B and Megtron 6 are often preferred for high-speed circuits due to their low loss tangent and dielectric constant, ensuring excellent signal transmission. Proper material selection is crucial for reducing power consumption, EMI/EMC issues, and ensuring reliable high-speed signal transmission. By choosing materials with ideal properties, designers can guarantee signal integrity and reliable signal transmission in high-speed circuits.

Thermal Management Needs

Effective thermal management is vital in high-speed circuit designs, as excessive heat buildup can compromise signal integrity, damage components, and undermine overall system reliability. In high-speed circuits, thermal management needs are essential to guarantee reliable performance and longevity.

The selection of materials with superior thermal management properties is critical to prevent overheating, which can lead to signal degradation, component damage, and system instability. Materials with high thermal conductivity, low thermal resistance, and excellent heat dissipation capabilities are ideal for high-speed circuits.

These materials facilitate efficient heat dissipation, thereby maintaining signal integrity, preventing component damage, and improving overall system reliability. The choice of materials with excellent thermal management characteristics has a significant impact on the efficiency and stability of high-speed circuits. By selecting materials with superior thermal management properties, designers can ensure that their high-speed circuits operate efficiently, reliably, and with minimal risk of component damage or system failure.

Effective thermal management is essential for achieving optimal system stability and reliability in high-speed circuit designs.

Optimizing Performance With the Right Material

When it comes to optimizing performance in high-speed circuits, material properties play a pivotal role. The selection of materials with ideal electrical and thermal characteristics is essential to minimize signal loss, maintain signal integrity, and guarantee reliable operation.

Material Properties Matter

In the domain of high-speed circuits, a plethora of material properties converge to dictate signal performance, with dielectric constant and dissipation factor emerging as paramount considerations. The selection of materials with essential properties is pivotal for achieving high-speed design goals.

Material properties that profoundly impact high-speed circuit performance include:

- Dielectric constant (Dk) and dissipation factor (Df): influencing signal loss and impedance control

- Thermal properties: affecting heat dissipation and material stability

- Moisture and chemical resistance: ensuring stable operation and preventing material degradation

- Electrical performance: impacting signal integrity and impedance control

Circuit Speed Demands

Optimizing high-speed circuit performance relies heavily on selecting materials that can mitigate signal degradation. The relentless pursuit of faster data transfer rates demands materials with exceptional dielectric properties. High-speed circuits require materials with low dielectric constant (Dk) and dissipation factor (Df) to minimize signal loss and maintain signal integrity.

Materials with low Dk and Df, such as Rogers 4350B and Megtron 6, are preferred for high-speed circuits due to their ability to reduce signal loss and maintain signal integrity. The rise and fall time of edge rates are critical considerations in selecting materials for high-speed circuits, as they directly impact signal integrity.

Proper material selection is essential for reducing power consumption and addressing EMI/EMC challenges in high-speed circuits. By selecting materials with excellent dielectric properties, designers can ensure reliable and efficient high-speed circuit performance.

Ultimately, the right material selection is essential for achieving high-speed circuit performance that meets the demands of modern applications.

Signal Integrity Key

By emphasizing signal integrity, designers can fully leverage the potential of high-speed circuits, as the careful selection of dielectric materials plays an essential role in maintaining signal fidelity and ensuring reliable performance.

In high-speed circuits, signal integrity optimization is vital, as it directly impacts performance and reliability.

To achieve the best signal integrity, designers must prioritize the following key factors:

- Dielectric material selection: Choosing materials with low loss tangent and dielectric constant, such as Rogers 4350B and Megtron 6, minimizes signal loss and ensures consistent impedance.

- Impedance consistency: Maintaining low loss and impedance consistency is critical for efficient signal transmission in high-speed PCB designs.

- Electromagnetic compatibility: Proper material selection enhances electromagnetic compatibility, reducing power and EMI/EMC issues.

- Power integrity: Optimizing signal integrity ensures reliable power delivery, reducing the risk of power integrity issues.

Frequently Asked Questions

Can High-Speed Circuits Be Built on Low-Cost FR4 Material?

Fastidious fabrication demands necessitate a nuanced examination of the feasibility of constructing high-speed circuits on low-cost FR4 material.

While FR4's affordability and widespread availability are undeniable, its limitations regarding dielectric loss, signal attenuation, and thermal instability necessitate careful consideration.

For high-speed applications, FR4's shortcomings may compromise signal integrity, rendering it a less-than-ideal choice for high-performance circuits.

Are There Any Eco-Friendly Alternatives to Traditional Circuit Materials?

When considering eco-friendly alternatives to traditional circuit materials, designers can explore bioplastics, recycled copper, and plant-based substrates. These innovative materials reduce environmental impact while maintaining performance.

For instance, bioplastics like polylactic acid (PLA) offer a biodegradable and renewable alternative to traditional plastics.

Similarly, plant-based substrates derived from bamboo or sugarcane can replace traditional FR4 materials, reducing carbon footprint and toxicity.

Do High-Speed Circuits Require Special Soldering Techniques?

In stark contrast to traditional circuit assembly, high-speed circuits demand meticulous attention to soldering techniques to guarantee signal integrity.

Unlike conventional methods, high-speed circuits require precise control of solder viscosity, temperature, and flux composition to prevent signal degradation.

Advanced techniques, such as reflow soldering and precision dispensing, are essential to minimize signal loss and secure superior performance in high-frequency applications.

Can I Use a Single Material for Both Analog and Digital Circuits?

When designing high-speed circuits, it's vital to contemplate the material selection for both analog and digital components.

While a single material for both circuits may seem attractive, it's important to prioritize signal integrity and noise reduction.

In reality, analog circuits often require low-loss, high-frequency materials, whereas digital circuits benefit from high-speed, low-latency materials.

A compromised material may not optimize performance for either circuit, leading to subpar system performance.

How Do Material Choices Impact Electromagnetic Interference Shielding?

Did you know that electromagnetic interference (EMI) can reduce circuit performance by up to 30%?

When it comes to material choices for high-speed circuits, EMI shielding is a critical consideration. The ideal material should have high conductivity, permeability, and magnetic shielding effectiveness.

Copper, for instance, is an excellent EMI shield due to its high conductivity and permeability. However, other materials like mu-metal or ferrite may be more suitable for specific applications.

Careful material selection is essential to minimize EMI and guarantee reliable circuit performance.