Thermal management solutions are vital for high-power devices, as excessive heat buildup can lead to reduced performance, premature failure, and even catastrophic failure. Effective heat sinks, cooling methodologies, and advanced technologies like heat pipes and Peltier cooling plates enhance heat dissipation. Material selection, thermal simulations, and proper design processes guarantee reliable thermal management. Emerging trends like nanomaterials, embedded cooling systems, and AI-driven algorithms further optimize thermal performance. As the demands on high-power devices continue to escalate, mastering thermal management is essential for ensuring peak performance and reliability, and there's more to explore on this critical topic.

Key Takeaways

- Effective thermal management solutions for high-power devices rely on minimizing thermal resistance through heat sinks, heat pipes, and advanced cooling technologies.

- Advanced materials like graphene, carbon nanotubes, and boron nitride nanotubes enhance heat dissipation and reduce thermal resistance in high-power devices.

- Thermal interface materials (TIMs) with high thermal conductivity are crucial for efficient heat transfer between surfaces in high-power devices.

- Proper PCB thermal management solutions, including thermal vias and heat sinks, prevent overheating and improve performance in high-power devices.

- Emerging trends in thermal management include nanomaterials, embedded cooling systems, AI-driven algorithms, and innovative cooling methods for high-power devices.

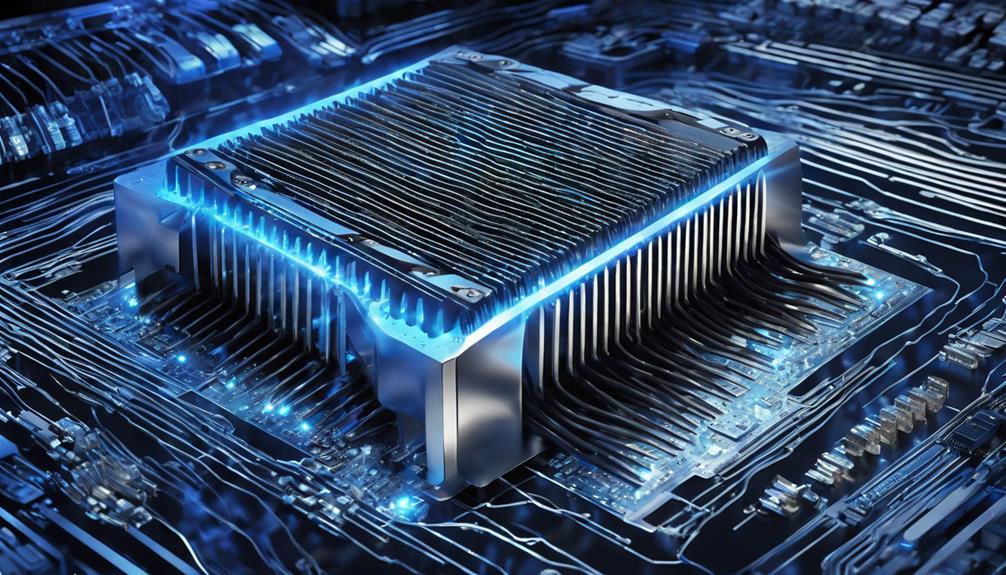

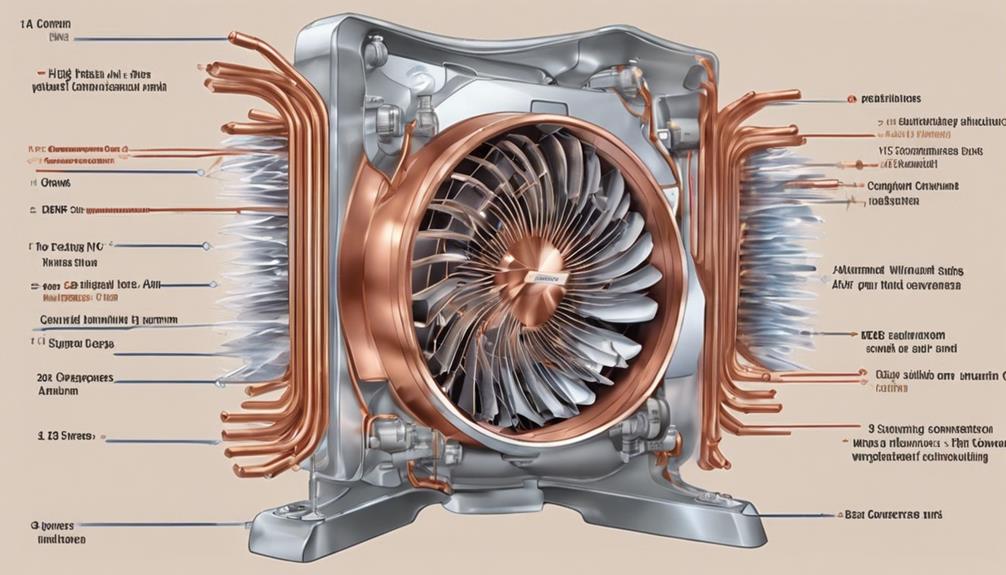

Thermal Resistance and Heat Sinks

In high-power devices, thermal resistance plays a critical role in determining the efficacy of heat dissipation, with lower values indicating superior heat transfer capabilities. Measured in degrees Celsius per watt (°C/W), thermal resistance is a key indicator of a device's ability to efficiently dissipate heat.

Heat sinks, an essential component in thermal management, facilitate heat transfer from the source to the surrounding environment, thereby maintaining safe operating temperatures and preventing overheating. By optimizing thermal conductivity and dissipation, heat sinks come in various designs and materials to suit specific high-power device applications.

Effective heat sink design and implementation are essential to minimize thermal resistance, ensuring efficient heat dissipation and reliable device operation. In high-power devices, the judicious selection and integration of heat sinks can greatly enhance overall thermal management, thereby guaranteeing excellent performance and longevity.

Cooling Methodologies and Materials

Frequently, high-power devices rely on advanced cooling methodologies and materials to maintain peak operating temperatures, thereby ensuring reliable performance and longevity. Effective cooling solutions are essential to prevent overheating, which can lead to reduced lifespan and even device failure.

Several advanced cooling methodologies and materials are employed to tackle thermal management challenges:

- Heat pipes: Utilize phase-change principles to transfer heat away from high-power devices.

- Synthetic jet air cooling: Generates vortices to enhance heat transfer coefficients in high-power electronic systems.

- Peltier cooling plates: Utilize the Peltier effect to provide precise temperature control for cooling electronic components.

- Electrostatic fluid acceleration: Pumps cooling fluid without the need for traditional moving parts, ideal for high-power applications.

Additionally, cold plates, made of thick metal, greatly improve heat transfer between heat sources and cooling fluids in high-power devices. These advanced cooling methodologies and materials are essential for maintaining the best operating temperatures, ensuring the reliability and longevity of high-power devices.

Advanced Cooling Technologies

The pursuit of efficient thermal management in high-power devices has led to the development of advanced cooling technologies that surpass the capabilities of traditional cooling methods.

Heat pipe technology, in particular, has emerged as a promising solution, leveraging the principles of phase-change heat transfer to efficiently manage thermal loads.

In tandem, advanced thermal materials with enhanced thermal conductivity are being explored to further augment the performance of cooling systems.

Heat Pipe Technology

Among the most effective advanced cooling technologies, heat pipe technology has emerged as a reliable solution for efficiently managing thermal loads in high-power devices. This technology utilizes phase change principles to facilitate efficient heat transfer, making it an ideal solution for high-power devices.

Here are some key benefits of heat pipe technology:

- Efficient heat transfer: Heat pipes enable rapid heat transfer through vaporization and condensation, ensuring efficient heat dissipation.

- Minimal thermal resistance: Heat pipes offer low thermal resistance, making them suitable for high-power devices that require peak performance.

- Passive cooling solutions: Heat pipes provide passive cooling solutions, eliminating the need for complex cooling systems.

- Reliability and versatility: Heat pipes are reliable and versatile, making them a popular choice for thermal management in high-power devices.

Advanced Thermal Materials

By harnessing the exceptional thermal properties of advanced materials like graphene, carbon nanotubes, and boron nitride nanotubes, high-power devices can achieve efficient heat dissipation and peak performance.

These advanced thermal materials boast high thermal conductivity, enabling the development of advanced cooling technologies such as heat spreaders, heat pipes, and thermal interface materials (TIMs). These technologies provide effective heat transfer pathways, reducing thermal resistance and maintaining safe operating temperatures.

Boron nitride nanotubes, in particular, are being researched for their superior thermal properties, enhancing thermal management in high-power devices. The integration of these advanced thermal materials in high-power devices guarantees optimal performance, reliability, and longevity by efficiently dissipating heat.

PCB Thermal Management Solutions

Several key strategies are employed in PCB thermal management solutions to mitigate excessive heat generation in high-power devices, guaranteeing peak performance and reliability. Optimizing the layout and design of printed circuit boards is essential for efficient heat dissipation. To achieve this, various techniques are utilized, including:

- Thermal vias: connecting copper planes to efficiently transfer heat away from high-power components.

- Heat sinks: attached to high-power components to increase the surface area for heat dissipation.

- Copper planes: used to spread heat across the PCB, enabling effective heat dissipation.

- Embedded heat pipes: advanced solutions that utilize phase-change materials to efficiently transfer heat.

Proper thermal management on PCBs helps prevent overheating, improves performance, and ensures the longevity of electronic devices.

Advanced PCB thermal management solutions also incorporate liquid cooling systems and thermal interface materials for top-notch heat dissipation.

Effective PCB thermal management is vital for maintaining safe operating temperatures and preventing thermal-induced failures in high-power electronic devices. By employing these strategies, designers can create high-performance, reliable, and efficient electronic devices.

Thermal Interface Materials Explained

In the domain of thermal interface materials, the selection of best-suited materials is crucial to guarantee efficient heat transfer between electronic components and heatsinks.

The thermal conductivity of these materials plays a crucial role in reducing thermal resistance, and the choice of interface fill materials can greatly impact the overall performance of the thermal management system.

Material Selection Criteria

Between the heat source and heat sink, a thermal interface material (TIM) plays an essential role in facilitating efficient heat transfer, making the selection of a suitable TIM an important aspect of thermal management in high-power devices. The choice of TIM greatly impacts the overall thermal performance of the system, and therefore, it is vital to take into account various selection criteria.

When selecting a TIM, the following factors must be taken into account:

- Thermal conductivity: The ability of the TIM to efficiently transfer heat.

- Viscosity: The flowability of the TIM, which affects its ability to fill gaps and conform to surfaces.

- Electrical insulation properties: The TIM's ability to prevent electrical shorts and ensure safe operation.

- Material compatibility: The TIM's compatibility with the heat source and heat sink materials.

Graphite-based TIMs, conductive adhesives, and gap fillers are popular choices for high-power applications due to their high thermal conductivity and ability to fill air gaps, ensuring effective heat transfer.

Thermal Conductivity Importance

Thermal conductivity, a vital property of thermal interface materials, plays a pivotal role in determining the efficiency of heat transfer between surfaces in high-power electronic devices. The thermal conductivity of a TIM (Thermal Interface Material) has a substantial impact on the heat dissipation efficiency and thermal resistance in electronic devices.

High thermal conductivity in TIMs enhances heat dissipation efficiency, reducing thermal resistance and ensuring effective heat transfer between components and heat sinks. This, in turn, maintains safe operating temperatures, prolonging the lifespan of high-power electronic devices.

Effective TIMs with high thermal conductivity fill gaps and irregularities between surfaces, ensuring maximum thermal contact for efficient heat dissipation. The choice of TIMs with appropriate thermal conductivity values is critical to maintain efficient heat transfer, reducing the risk of overheating and device failure.

Interface Fill Materials

Five primary categories of interface fill materials are used in high-power electronic devices to facilitate efficient heat transfer between heat-generating components and heat sinks. These materials include thermal greases, pads, tapes, and phase change materials. Thermal interface materials (TIMs) are crucial in reducing thermal resistance and enhancing thermal conductivity between surfaces.

To optimize thermal performance, the selection of TIM depends on various factors such as operating temperatures, pressure requirements, application longevity, and surface conductivity. It is essential to choose a TIM that can withstand the device's operating temperature range and ensure good surface conductivity for effective heat transfer.

Proper application of TIMs is vital for achieving excellent thermal performance and reliability in high-power devices. Designers can significantly enhance the efficiency and reliability of their devices by selecting the appropriate TIM and applying it correctly.

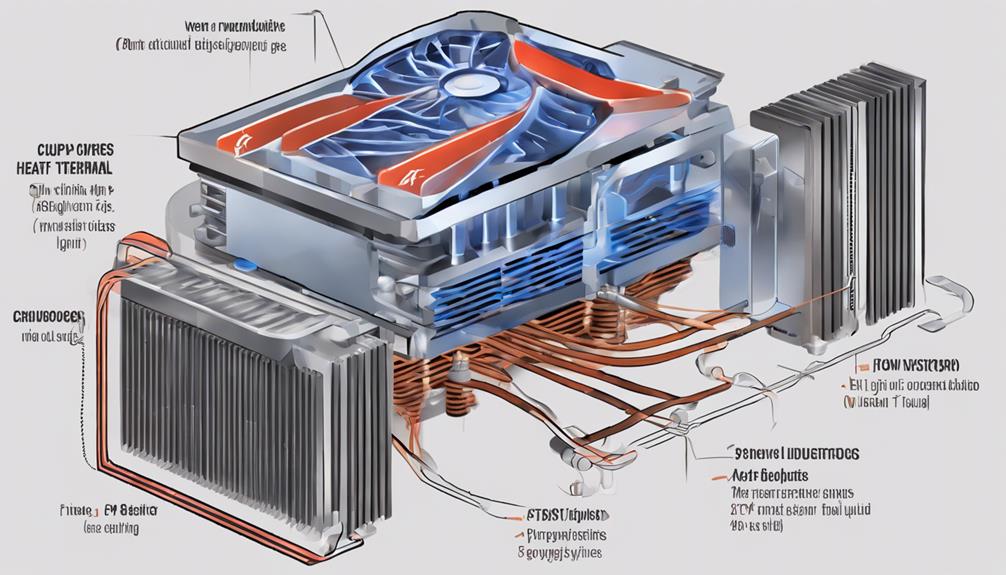

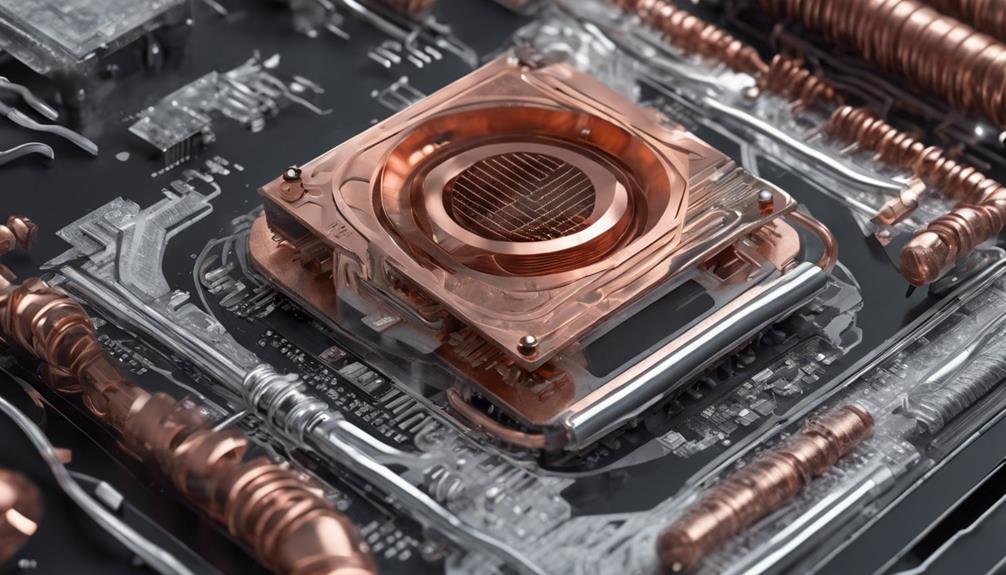

Heat Pipe and Cold Plate Solutions

In high-power applications, the synergy of heat pipes and cold plates offers a potent combination for efficient heat dissipation, leveraging the strengths of each technology to guarantee reliable operation.

Heat pipes efficiently transfer heat using phase change principles, with high thermal conductivity materials like copper or aluminum. This enables rapid heat transfer over long distances, making them ideal for high-power devices.

Cold plates, on the other hand, provide a larger surface area for heat exchange and can be customized to fit specific device configurations. They enhance heat transfer between a heat source and a cooling fluid, making them well-suited for high-power applications.

By combining heat pipes and cold plates, a thorough cooling solution is achieved, improving overall system reliability. The heat pipes rapidly transfer heat to the cold plate, which then efficiently dissipates the heat to the cooling fluid.

This hybrid approach ensures that high-power devices operate within a safe temperature range, preventing overheating and maintaining peak performance. Accordingly, heat pipe and cold plate solutions are a popular choice for thermal management in high-power devices.

Peltier Cooling Plate Applications

By leveraging the Peltier effect, Peltier cooling plates provide a precise and compact solution for efficiently cooling high-power electronic components, particularly in applications where traditional heat sinks are ineffective. These plates utilize the Peltier effect to create a temperature difference, allowing for efficient heat transfer and precise temperature control.

Here are some key benefits of Peltier cooling plates:

- Compact design: Peltier cooling plates are ideal for applications where space is limited, providing a compact solution for cooling high-power devices.

- Accurate temperature control: These plates offer accurate temperature control, ensuring ideal operating temperatures for high-power devices.

- Below-ambient cooling: Peltier cooling plates can achieve below-ambient cooling, making them ideal for applications where overheating is a concern.

- Effective heat transfer: The Peltier effect enables effective heat transfer, ensuring that heat is transferred away from electronic components, maintaining ideal operating temperatures.

Air Cooling and Convection Methods

Within the domain of air cooling and convection methods, natural convection techniques and heat sink design emerge as pivotal components in thermal management solutions.

Natural convection techniques, which rely on passive airflow, are often employed in applications where space and power constraints are paramount.

The design of heat sinks plays a critical role in optimizing heat dissipation. Careful consideration of their geometry, material, and surface finish is essential for effective thermal management.

Natural Convection Methods

Employing natural convection principles, air cooling and convection methods leverage the inherent movement of air to efficiently dissipate heat from high-power devices. This approach is essential for maintaining safe operating temperatures and preventing overheating, which can lead to reduced performance, reliability issues, or even complete system failure.

Natural convection methods are widely used due to their cost-effectiveness and simplicity. Here are some key benefits of natural convection methods:

- Cost-effective: Air cooling solutions are often less expensive than other thermal management methods.

- Efficient heat dissipation: Convection methods can efficiently transfer heat away from high-power devices.

- Wide applicability: Air cooling solutions are suitable for various applications, including electronics, automotive, and industrial systems.

- Reliable operation: Natural convection methods ensure dependable functioning by averting overheating and maintaining ideal temperatures.

Heat Sink Design

Well-designed heat sinks are essential components in air cooling and convection methods. They facilitate efficient heat dissipation from high-power electronic devices through a combination of conduction and convection.

Effective heat sink design involves careful consideration of heat sink geometries, thermal resistance, and surface area optimization. This is done to minimize thermal resistance and maximize heat dissipation efficiency. Material choice also plays a critical role, as it directly impacts thermal conductivity and heat dissipation rates.

Convection methods, including natural and forced convection, rely on heat transfer through the movement of air to dissipate heat away from the heat sink. Forced convection, in particular, offers higher cooling rates compared to natural convection, making it a popular choice for high-power applications.

Liquid Cooling and Flow Rates

In high-power devices, liquid cooling systems rely on precisely controlled flow rates to effectively dissipate heat and maintain ideal operating temperatures. The coolant's flow rate plays a critical role in heat dissipation, as it directly affects the system's ability to remove heat from the device.

Here are some key considerations for flow rates in liquid cooling systems:

- Essential flow rates: Ensure consistent cooling performance and prevent hot spots in high-power devices.

- Inadequate flow rates: Can lead to insufficient heat dissipation, resulting in thermal issues and potential damage to components.

- Monitoring flow rates: Essential for maximizing cooling efficiency and protecting high-power devices from overheating.

- Adjusting flow rates: Important for maintaining ideal temperatures and preventing thermal issues in high-power devices.

Thermal Simulation and Modeling

Thermal simulation and modeling tools have become essential components of the design process, enabling engineers to optimize thermal performance and guarantee reliable operation of high-power devices. Advanced software tools, such as Ansys IcePak and Mentor Graphics FloTHERM, facilitate thermal simulation and modeling, allowing engineers to visualize temperature distributions and airflow in electronic devices.

Through thermal modeling, engineers can analyze and improve heat transfer efficiency in high-power devices, identifying potential hot spots and optimizing heat dissipation. Simulation results provide valuable insights into thermal behavior, aiding in the development of effective cooling solutions.

By simulating thermal performance, engineers can validate designs, optimize heat dissipation, and ensure devices operate within safe temperature limits. This enables the creation of reliable and efficient thermal management solutions, critical for high-power devices.

Optimizing Thermal Performance

By leveraging advanced materials and innovative cooling technologies, engineers can optimize thermal performance in high-power devices, ensuring reliable operation and minimizing the risk of thermal-related failures.

To achieve the best thermal performance, engineers can employ various strategies:

- Selecting materials with high thermal conductivity: Copper and diamond are prime examples of materials that excel in heat dissipation.

- Efficient heat dissipation: Heat sinks and heat spreaders are essential components in high-power devices, facilitating efficient heat transfer.

- Thermal simulations: Visualizing temperature distribution and airflow helps optimize the design for maximum cooling.

- Active cooling technologies and thermal interface materials: Thermoelectric coolers and thermal interface materials (TIMs) can greatly enhance thermal performance in high-power electronic components.

Design and Verification Process

Effective thermal management solutions depend on a rigorous design and verification process to guarantee that high-power devices operate within a safe temperature range, mitigating the risk of thermal-related failures.

During the design phase, material selection is critical, as materials with high thermal conductivity, such as copper or diamond, are essential for efficient heat dissipation.

Thermal simulations play an important role in optimizing designs, visualizing temperature distributions, and ensuring efficient heat dissipation.

Verification of thermal designs is essential to prevent delays and cost overruns in high-power device development. Fixing thermal design issues early in the process saves time and resources during the development of high-power devices.

Early consideration of thermal properties in the design phase leads to innovative and effective thermal management solutions. By integrating thermal considerations into the design process, developers can create high-power devices that operate reliably and efficiently.

A thorough design and verification process ensures that thermal management solutions meet the demands of high-power devices, enabling excellent performance and reliability.

Emerging Trends in Thermal Management

As the pursuit of enhanced thermal performance intensifies, innovative solutions are emerging to tackle the complexities of heat management in high-power devices. The thermal management landscape is evolving, driven by the need for efficient heat dissipation in advanced electronic components.

Some of the key emerging trends in thermal management include:

- Nanomaterials: Enhancing thermal conductivity in high-power devices through the adoption of nanomaterials.

- Embedded Cooling Systems: Managing heat in advanced electronic components with embedded cooling systems.

- AI-Driven Algorithms: Revolutionizing thermal management with AI-driven algorithms that optimize heat control.

- Advanced Digital Threads: Enabling efficient thermal management strategies through the integration of advanced digital threads.

These emerging trends are transforming the way heat is managed in high-power devices.

Innovative cooling methods, such as heat pipes, are also being increasingly utilized to address thermal challenges.

As the demand for high-performance electronics continues to grow, these emerging trends will play a critical role in shaping the future of thermal management.

Frequently Asked Questions

What Is Thermal Management in Power Electronics?

Thermal management in power electronics refers to the deliberate control and regulation of heat generation and dissipation to maintain ideal operating temperatures. This critical process guarantees that electronic components operate within safe temperature limits, preventing overheating-related failures and premature degradation.

Effective thermal management is essential to extend the lifespan, reliability, and performance of high-power devices, enabling them to function efficiently and sustainably.

How Does a Thermal Management System Work?

A thermal management system is the unsung hero that saves high-power devices from the brink of catastrophic failure, working tirelessly behind the scenes to regulate temperature and prevent overheating.

It achieves this through a trifecta of heat transfer mechanisms: conduction, convection, and radiation.

What Are the Thermal Management Strategies?

Thermal management strategies for high-power devices encompass a range of techniques to dissipate heat efficiently and prevent overheating. These strategies include heat sinks, heat spreaders, liquid cooling systems, and active cooling techniques.

Each approach is designed to maintain safe operating temperatures, ensuring peak performance, reliability, and longevity of electronic components.

What Is the Thermal Management System in Electric Vehicles?

In electric vehicles, the thermal management system is a critical component that guarantees ideal operating temperatures of high-power components. This system utilizes advanced cooling technologies, such as liquid cooling and heat sinks, to dissipate heat effectively.